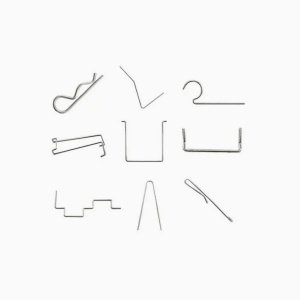

About Wire Forms

Wire forms are precisely shaped wire components, custom-engineered to perform specific mechanical functions beyond conventional coil springs. Designed through bending, shaping or cutting wire into various configurations, wire forms serve as essential elements in countless industrial, commercial and consumer applications.

Manufacturing Technology

At ZW Precision Hardware, we employ sophisticated manufacturing techniques, including advanced CNC wire bending, precision forming, automated cutting, stamping and welding processes, ensuring accurate dimensions, consistent quality and reliable performance. We expertly work with a wide variety of materials such as stainless steel, carbon steel, titanium alloys, phosphor bronze and specialized alloys to meet diverse customer specifications and rigorous industry standards.

Strengths of ZW Precision Hardware

A distinctive strength of our operation is our rapid and responsive customer service, providing prompt quotations, quick prototype production and efficient manufacturing turnaround, significantly shortening lead times. We maintain strict compliance with international quality standards including ISO 9001 certification, and our comprehensive quality assurance includes rigorous inspections, dimensional verification, load testing and corrosion resistance evaluations.

Introduction of Wire Forms Usage

Wire forms from our facilities find extensive usage across numerous sectors, including automotive components, medical instruments, electronics, agricultural machinery, industrial equipment, retail displays and consumer products. Our commitment to continuous innovation and advanced technological integration enables us to deliver customized wire form solutions tailored precisely to the unique needs and performance demands of each industry and application.

.png)