About ZW Precision Hardware

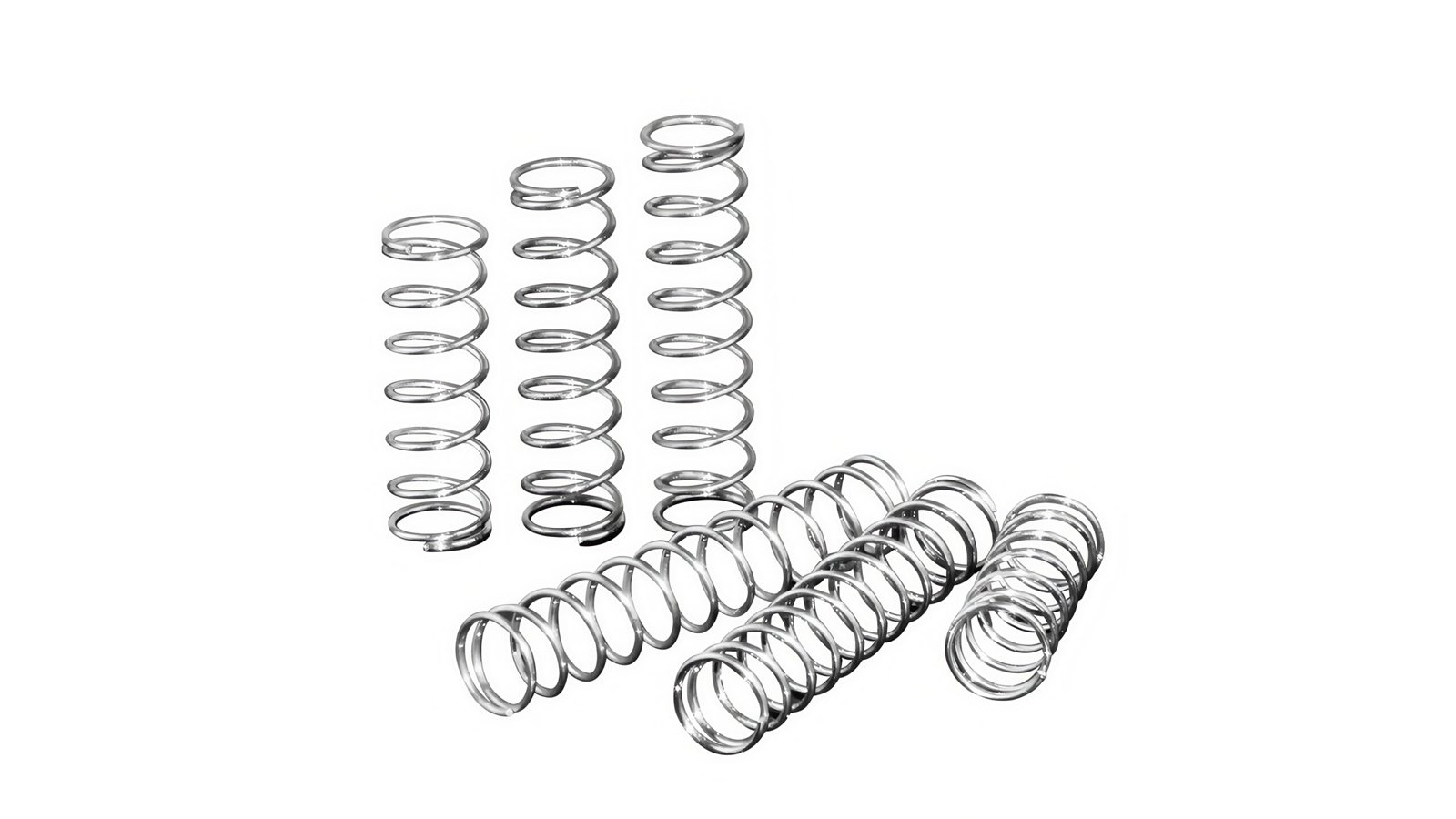

Founded in 1998, ZW Precision Hardware specializes in the custom manufacturing of precision springs, stampings, wire forms and non-standard hardware components. Our products are widely used in medical, industrial, household and office automation. With over 20 years of experience and ISO 9001 certification, we are committed to being a trusted supplier of precision components to serve global clients.

Our Service Process

When you send us your drawings, specifications, or design concepts via phone, email, or our online form, our team of professional sales engineers will respond within 24 hours. They possess not only commercial knowledge but also a deep engineering background, allowing them to quickly understand your core requirements and technical challenges, setting the stage for an efficient partnership from day one.

Upon receiving your inquiry, the project is immediately transferred to our engineering team. They conduct a comprehensive Design for Manufacturability (DFM) analysis of your design, evaluating the rationality of material selection, tolerance settings, structural form, and forming processes. We proactively provide constructive feedback aimed at:

- Optimizing Performance: Ensuring the component perfectly achieves its intended function.

- Reducing Cost: Finding the most cost-effective manufacturing solution by improving the design or process.

- Enhancing Reliability: Foreseeing and mitigating potential manufacturing risks in advance. A detailed technical proposal and quotation will be completed and submitted to you at this stage.

Once the technical proposal is approved, we utilize our advanced rapid prototyping capabilities to create samples for you. Whether through CNC machining, laser cutting, or dedicated sample machinery, we can provide high-precision, functional prototypes in the shortest possible time for your assembly and performance testing. We believe that a physically validated prototype is the only standard for launching mass production.

As soon as the prototype is confirmed, we activate our efficient, modern production workshops. Whether for precision springs, stampings, or wire forms, our production lines are highly automated and utilize Statistical Process Control (SPC) for real-time monitoring of key parameters. Our production management system ensures the accurate flow of order information, making every step from raw material input to finished product packaging orderly and fully traceable.

We execute a multi-layered quality inspection process that runs through every stage of production. This is not just a final step but a habit integrated into every process.

- IQC (Incoming Quality Control): Ensures all raw materials meet specifications.

- IPQC / PQC (In-Process / Process Quality Control): First-article, patrol, and operator self-inspections during production.

- FQC (Final Quality Control): A comprehensive inspection of finished goods, either 100% or according to AQL standards.

- OQC (Outgoing Quality Control): A final verification before packaging and shipment. We guarantee that every component delivered to you is 100% compliant with your drawings and specifications.

We provide comprehensive after-sales support for all our products. Whether you have questions about product performance, technical issues during application, or follow-ups for future orders, your dedicated customer service team is always on standby. We value the long-term partnerships we build with every client and are committed to providing you with continuous support and service.

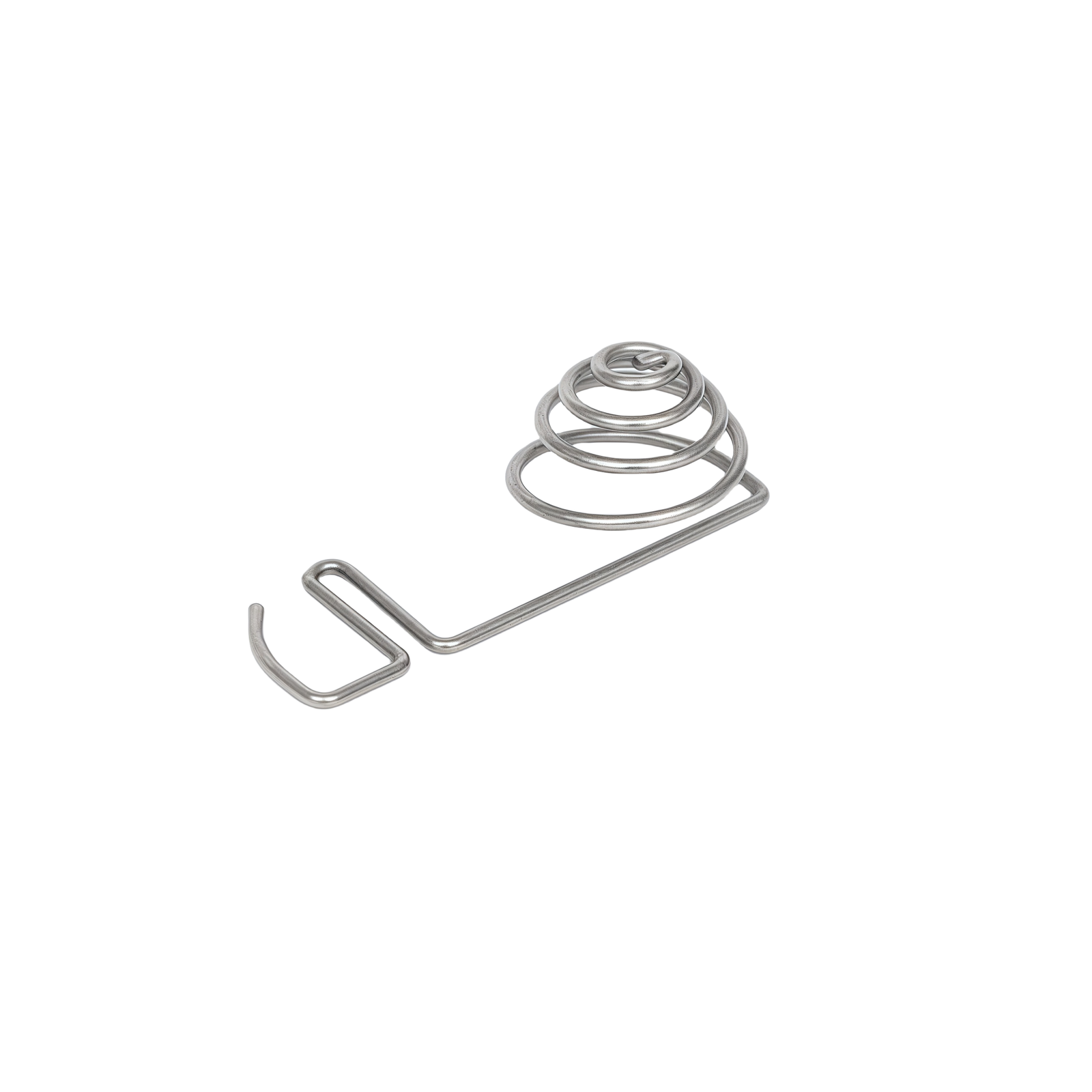

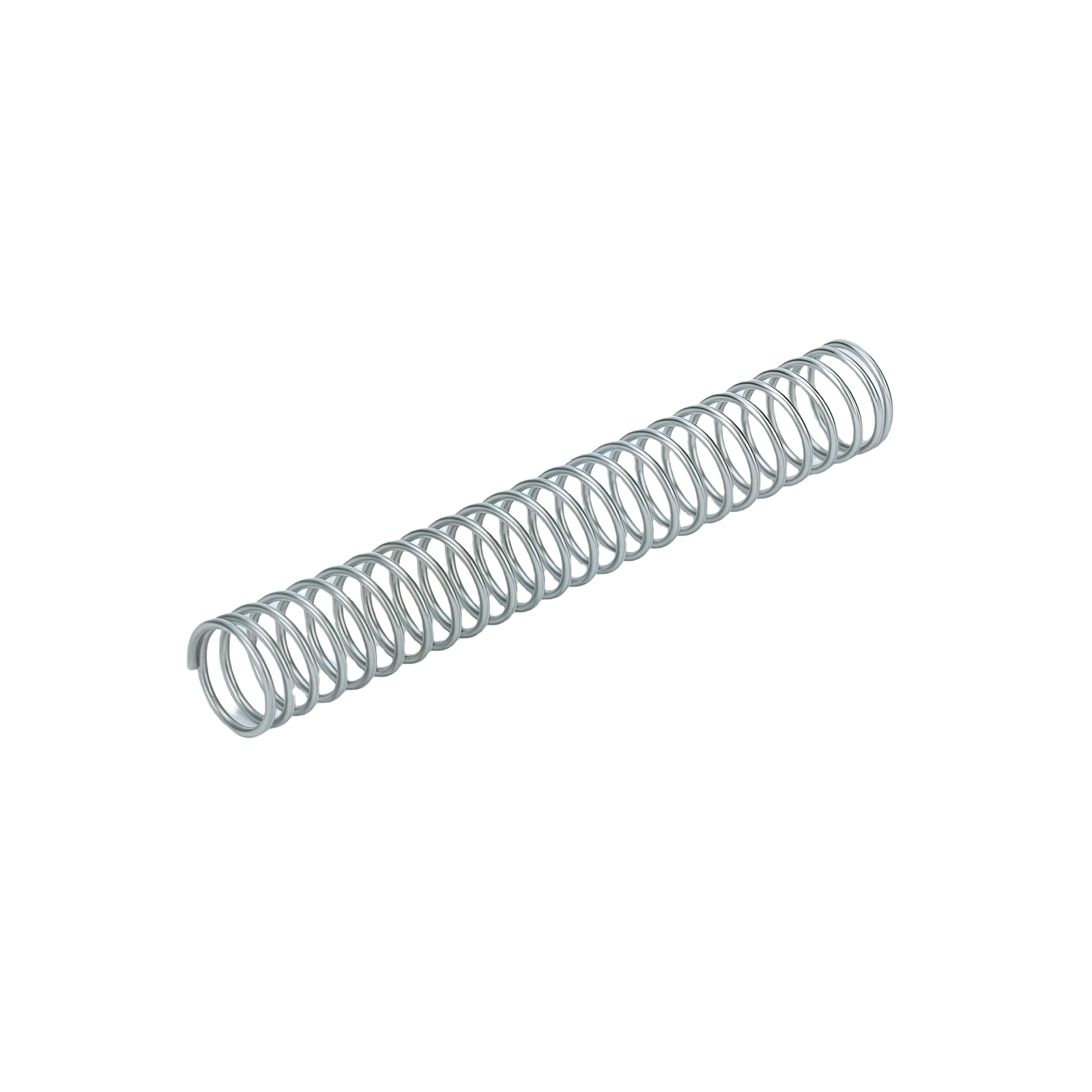

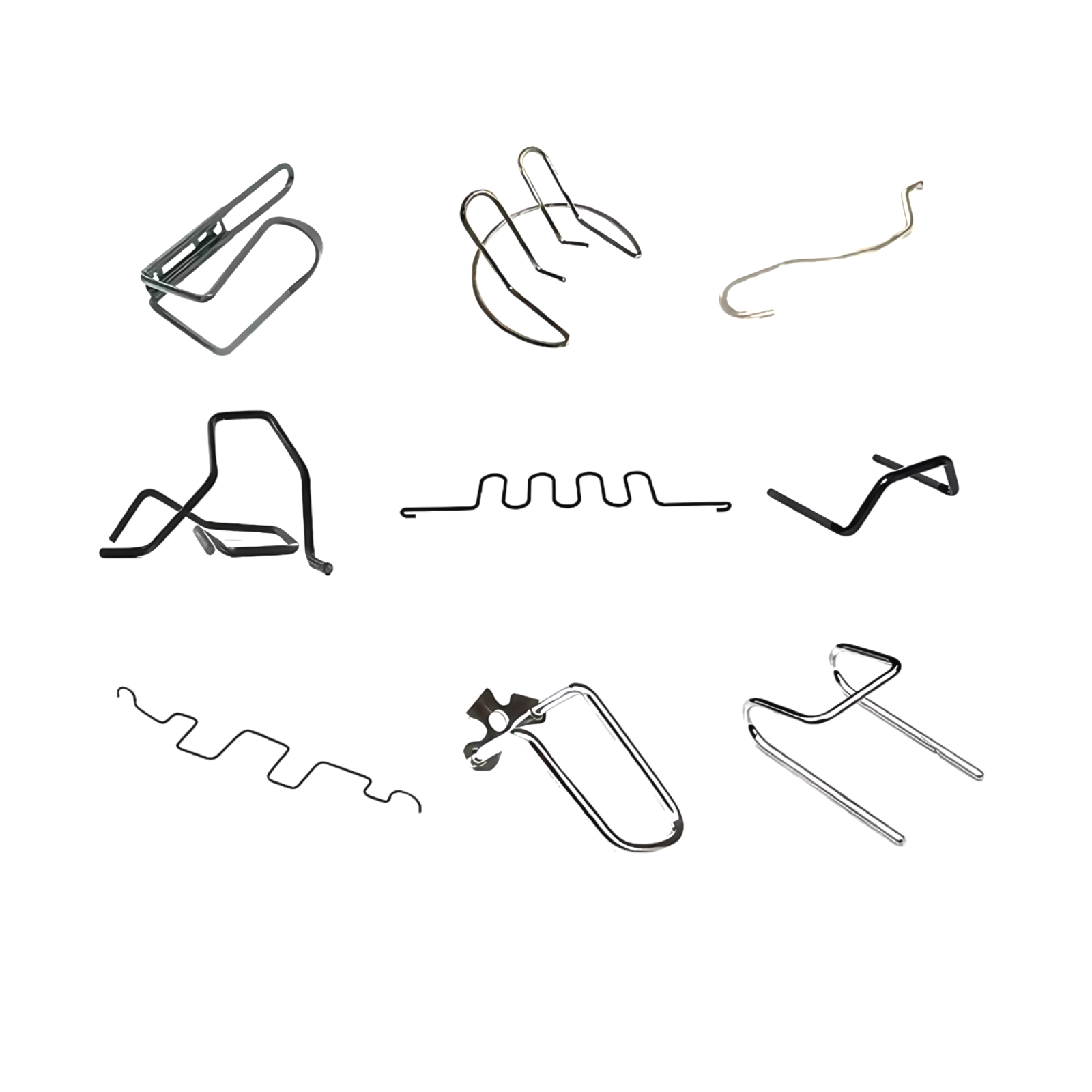

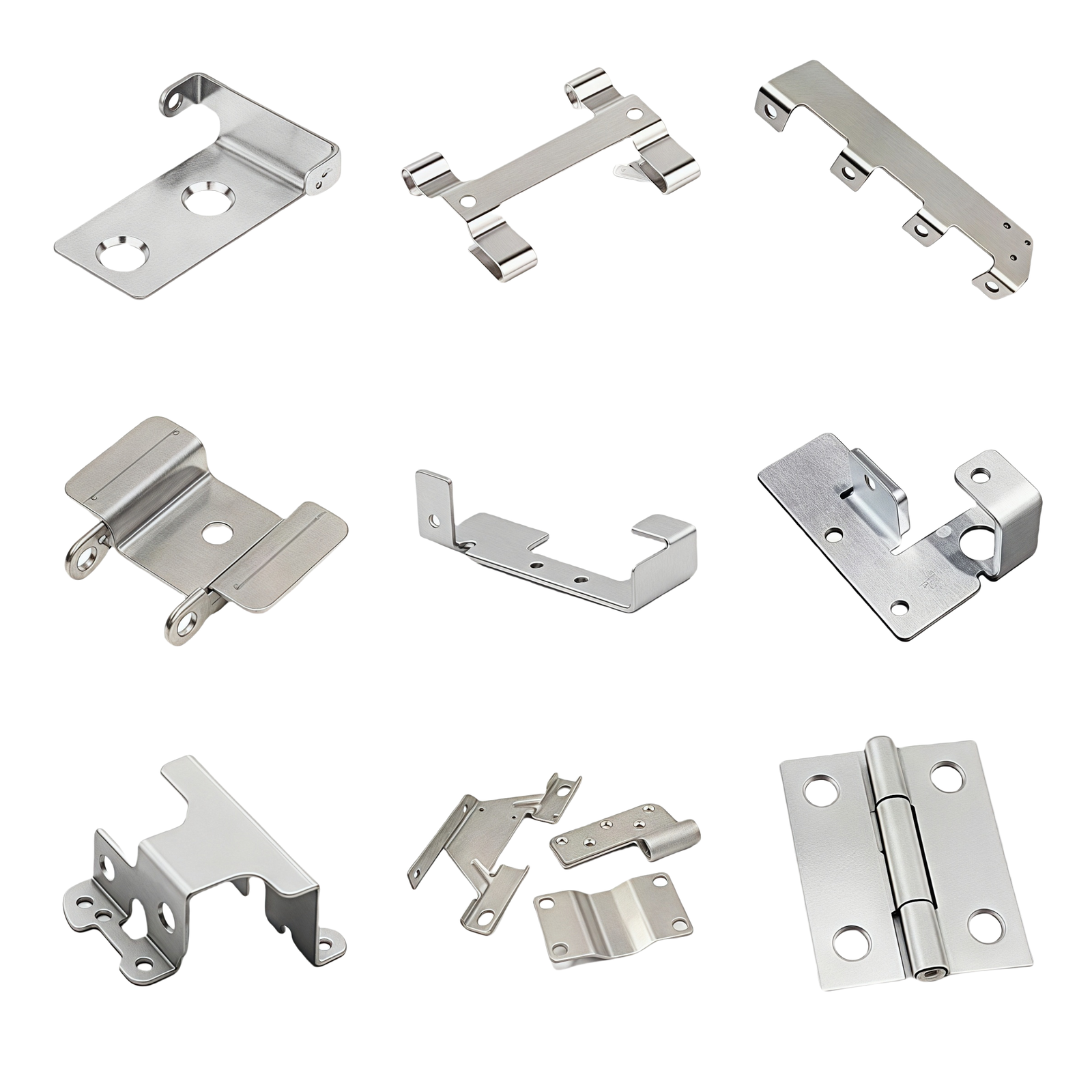

Our Products

Our Strengths

Need precision springs tailored to your requirements?

Contact us today for a free consultation!

@Copyright 2025 | ZW Precision Hardware

.png)