– Drive Springs for Medical Snares: Empowering Precision Control and Reliable Actuation

We provide core spring components for the handle drive, ratchet, and safety mechanisms of medical snares, ensuring physicians experience a smooth feel, clear feedback, and absolute reliability during procedures.

Snare Technology Overview: The Mechanical Core Behind Precision Control

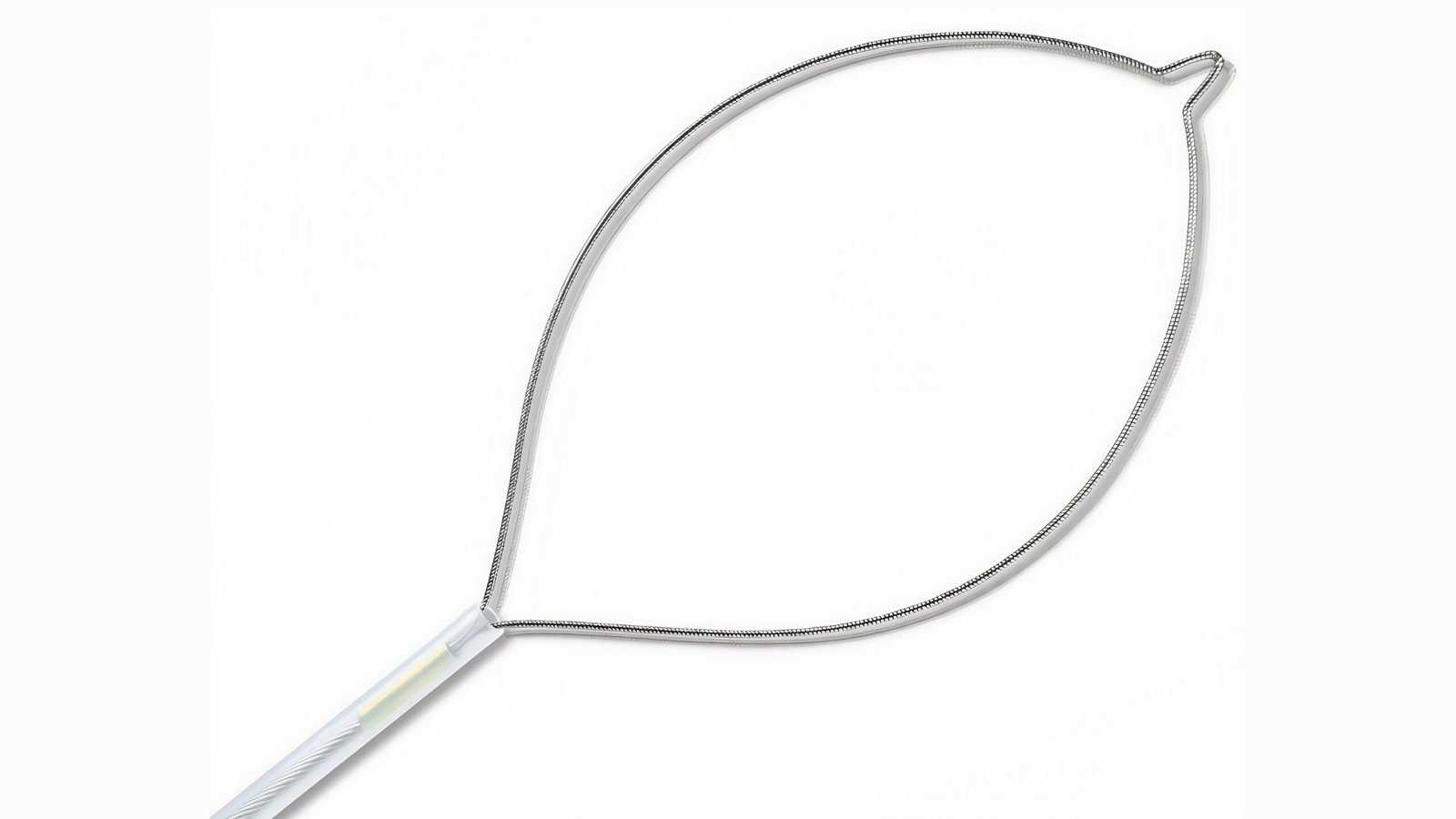

In endoscopy, a snare is the surgeon’s “extended arm” for performing delicate procedures like polypectomy. While the snare wire itself is critical, the physician’s ability to smoothly and stably control the loop’s deployment, positioning, and tightening depends entirely on the actuation handle. The sophisticated mechanical drive system inside a well-designed handle is the soul of precise control, and precision springs are the indispensable core components of this system.

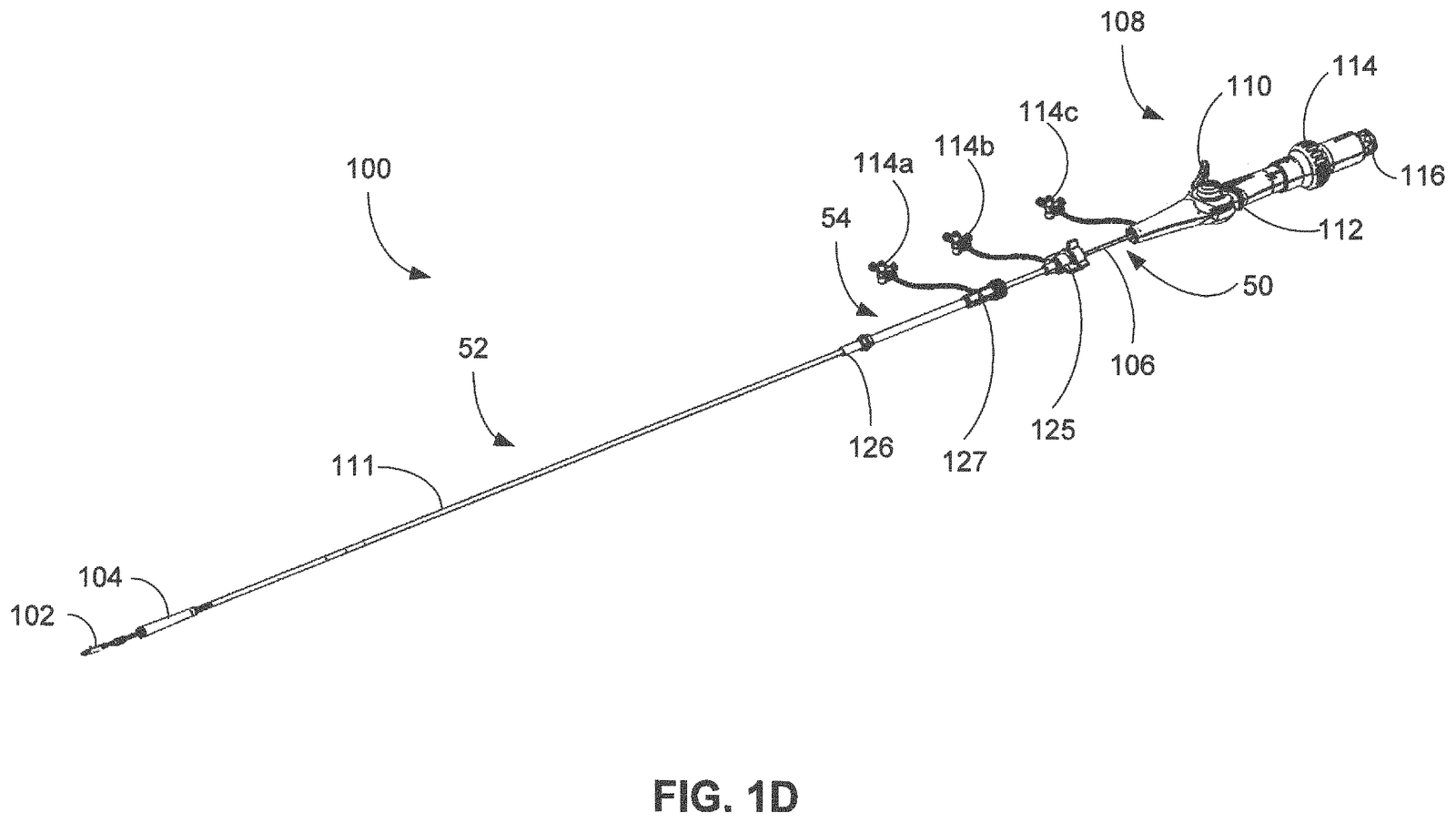

FIG. 1D is one embodiment of a system for retrieving a leadless pacemaker.

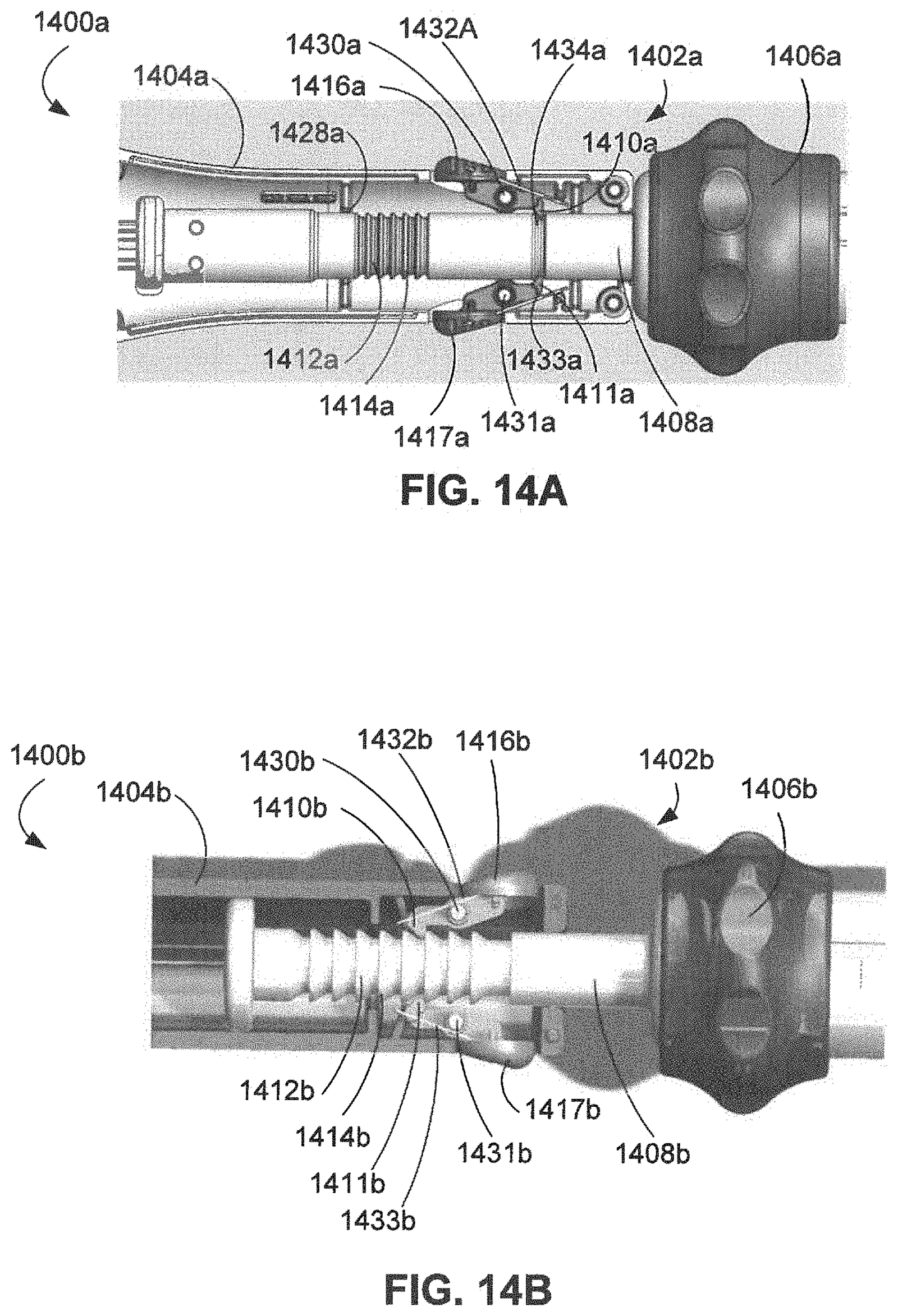

FIGS. 14A-14B illustrate alternative implementations of tensioning assemblies in accordance with this disclosure, each of which may be implemented in a retrieval system, such as the system 100 of FIG. 1D.

As shown in FIG. 14A, the pawls 1410 a are coupled to mounting pins 1430 a, 1431 a extending through the distal handle portion 1404 a. Each of the pawls 1410 a, 1411 a includes a button 1416 a, 1417 a that, when depressed, causes rotation of the respective pawl 1410 a, 1411 a about the mounting pins 1430 a, 1431 a. Each of the pawls 1410A, 1411 a further includes a biasing member 1432 a, 1433 a adapted to bias the pawl 1410 a towards the shaft 1408 a. In the example implementation of FIG. 14A, the biasing members 1432 a, 1433 a are in the form of sheet metal springs. In other implementations, each biasing member 1432 a, 1433 a may instead be, among other things, a torsion spring coiled about a respective mounting pin 1430 a, 1431 a.

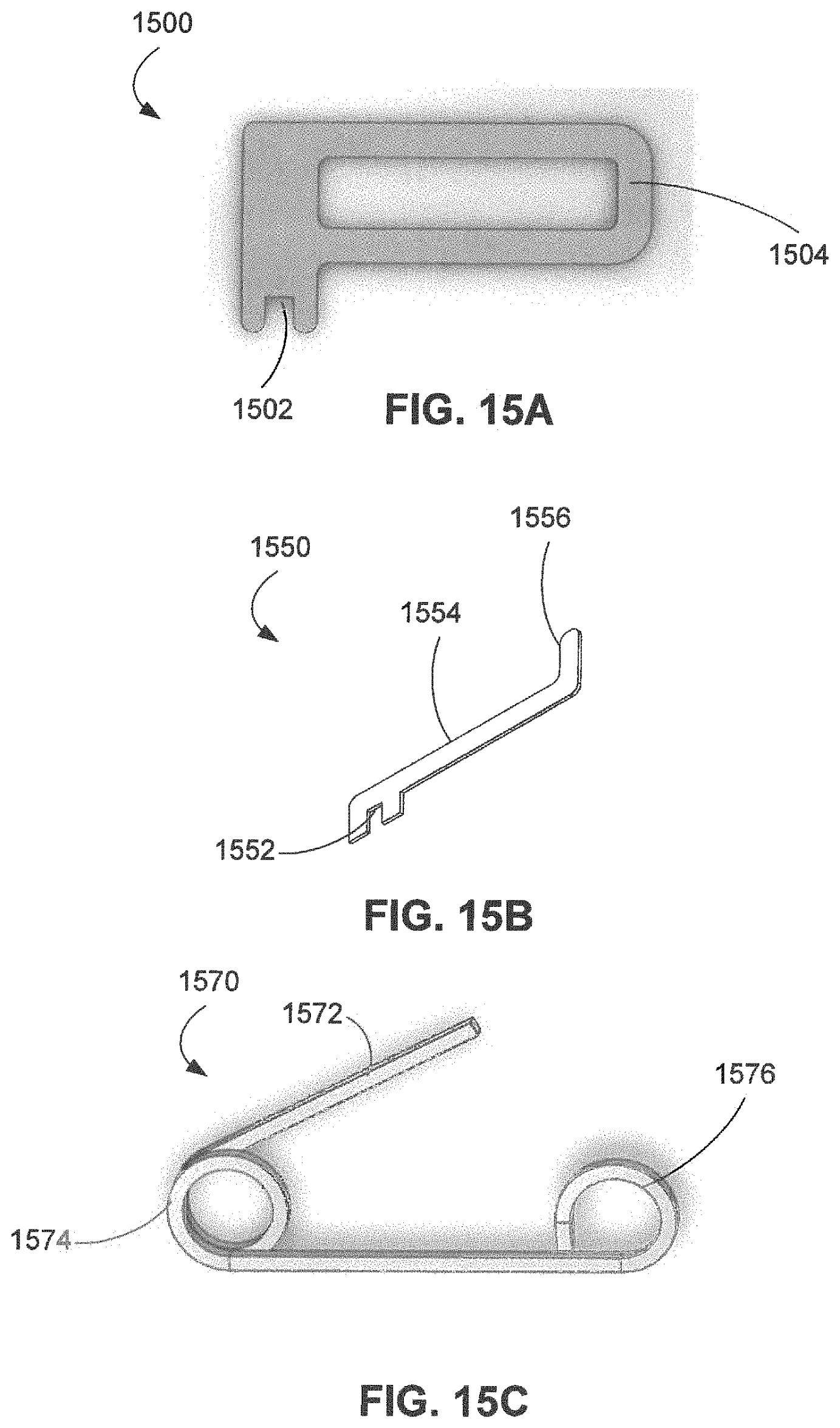

FIG. 15C is a side elevation view of a third example of a biasing member 1570 that may be implemented in the as the biasing members 1432 a, 1433 a and 1432 b, 1433 b of FIGS. 14A and 14B, respectively.

From the main drive spring that provides smooth sliding resistance to the ratchet spring that enables staged locking, the performance of every single spring directly impacts the physician’s operating experience and the success rate of the surgery. We specialize in manufacturing these “unsung heroes” hidden inside the handle, providing superior mechanical performance for your snare products.

Medical Snare Spring Solutions

We deeply understand that different types of snare procedures have vastly different requirements for the handle’s mechanical feedback and functionality. Therefore, we do not offer a “one-size-fits-all” spring. Instead, we provide custom-engineered spring solutions, precisely calculated and optimized for each specific application.

Polypectomy Snares

- Challenge: Polypectomy requires the physician to accurately place the snare loop over the polyp’s stalk and ensure a secure purchase through staged tightening before applying electrosurgical current. This process demands a handle with a reliable incremental locking function and a smooth feel for fine adjustments.

- Our Solution:

- Ratchet Mechanism Springs: We provide high-precision, high-fatigue-life micro compression springs to actuate the pawl within the ratchet mechanism. This spring delivers a crisp, reliable “click” and tactile feedback, allowing the physician to clearly perceive and lock each stage of tightening, preventing slippage.

- Main Actuation Springs: Our engineered main drive compression springs feature a smooth force-deflection curve, ensuring that when the physician performs delicate opening, closing, and positioning maneuvers, the feel is smooth and free of any catching, facilitating easy fine-tuning.

Foreign Body Retrieval Snares

- Challenge: When retrieving foreign bodies from the GI tract (such as swallowed batteries or fish bones), the physician may need to repeatedly and rapidly open and close the snare loop to find the optimal angle and position for grasping. This places high demands on the handle’s rapid auto-return and operator comfort.

- Our Solution:

- Main Actuation Springs:Our solution here focuses on exceptional fatigue life. We utilize specialty stainless steel materials combined with a pre-setting process to ensure that after thousands of high-frequency push-pull cycles, the spring’s force and auto-return performance remain robust and consistent, significantly reducing operator fatigue.

Tissue Resection Snares

- Challenge: When performing larger-scale resections like Endoscopic Mucosal Resection (EMR), the snare loop encounters greater resistance. This presents a severe test for the handle’s locking strength and overall structural reliability.

- Our Solution:

- High-Strength Ratchet Springs: For these applications, we provide stronger, more robust ratchet mechanism springs with a higher force value. This ensures the pawl locks securely into the gear teeth and will not slip, even when encountering significant resistance, providing a crucial safety guarantee for a successful resection.

- Reinforced Main Actuation Springs: We can design main drive springs with a higher load capacity, allowing the physician to feel stronger support when tightening the loop, thus performing the resection of tougher tissue with greater confidence.

Micro-snares for Minimally Invasive Procedures

- Challenge: Micro-snares used in tiny anatomical structures like the biliary or pancreatic ducts require extreme miniaturization of the handle and its internal components. The challenge is to achieve reliable mechanical function and clear tactile feedback within a microscopic space.

- Our Solution: We have the capability to produce ultra-fine precision springs with wire diameters as small as 0.05mm (0.002″). Whether it’s a drive spring for a micro-slider or an actuation spring for a micro-ratchet, we can control its mechanical properties with precision while maintaining its minute size, ensuring that even micro-instruments possess the same reliable and clear operational feel as their standard-sized counterparts.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | 304 Stainless Steel, Music Wire |

| Core Processes | Precision Coiling, Force-Curve Design & Testing, Fatigue Life Testing, Automated Inspection |

| Wire Diameter | 0.1mm – 1.0mm (0.004″ – 0.039″) |

| Outer Diameter | 1.0mm – 10mm (0.039″ – 0.394″) |

| Force Control Tolerance | As tight as ±5% |

| Cycle Life | Can be designed and tested to meet >10,000 cycle requirements |

Core Performance Advantages

Smooth & Tactile Operation

Our custom force curves translate the physician’s intent into smooth mechanical action.

Reliable Auto-Return

Our springs feature exceptional fatigue life, ensuring the handle returns to its home position precisely, even after thousands of uses.

Crisp Mechanical Feedback

Delivers a clear, satisfying “click” and tactile feel for ratchet and locking mechanisms, boosting operator confidence.

Excellent Performance Consistency

Strict process controls ensure that from the first spring to the millionth, the performance is identical.

.png)