– The Power Core for Drug Delivery Systems: Precision Driven, Reliability Infused

We provide power and control springs with ultra-high reliability, exceptional fatigue life, and precise force output for all types of infusion pumps, insulin pumps, and auto-injectors.

Drug Delivery System Technology Overview: Precision Dosage, Life’s Dependability

From continuous drug infusion pumps in hospitals to daily-use insulin pens for diabetic patients and emergency epinephrine auto-injectors, accurate and reliable drug delivery is a cornerstone of modern healthcare. At the heart of these devices, springs play an indispensable role: they can be the “engine” that powers the injection or the “regulator” that controls the dosage. Any minor deviation in force or performance degradation can lead to serious clinical consequences.

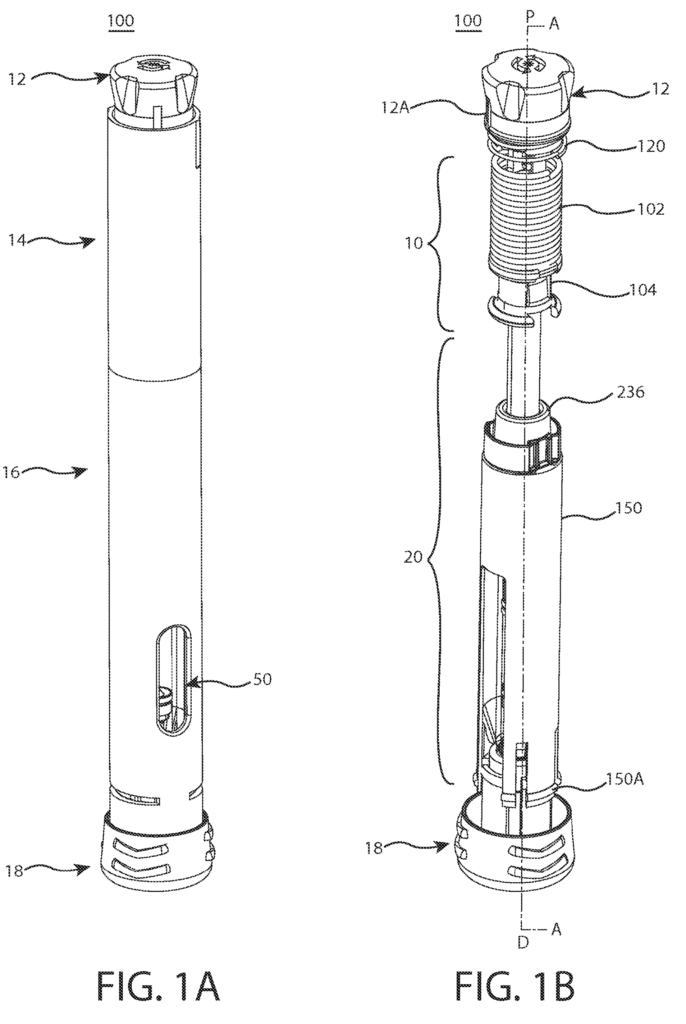

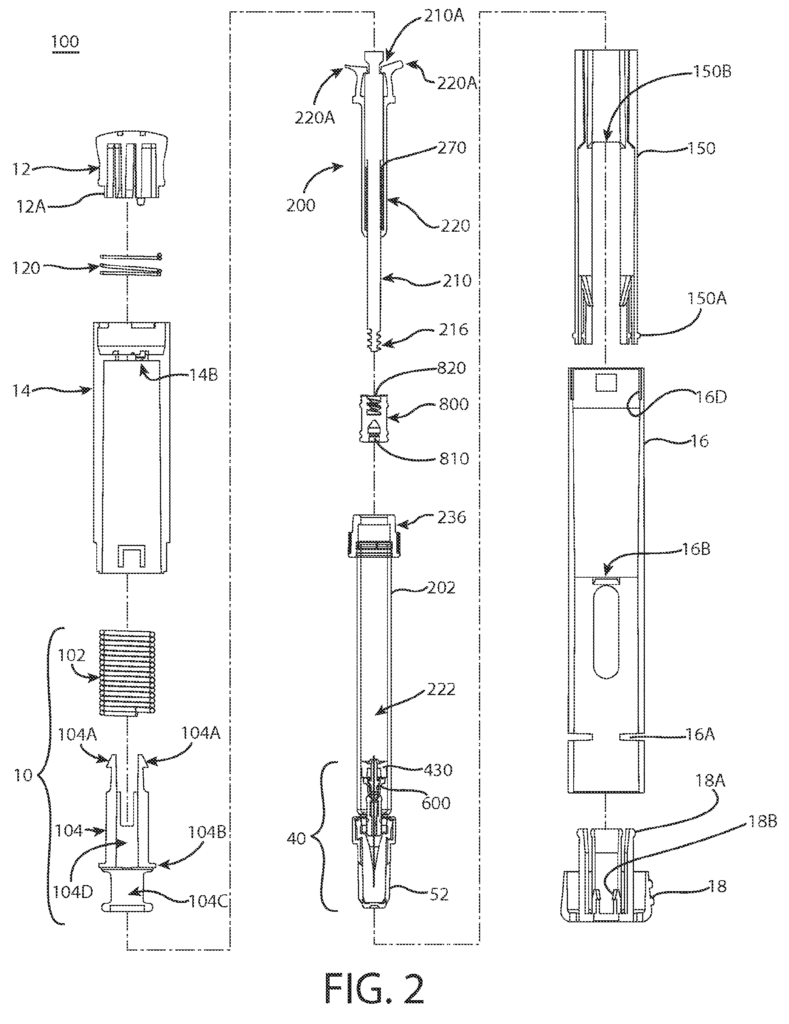

FIG. 1A shows an isometric view of an automatic injector according to one embodiment; FIG. 1B shows an isometric view of the interior components of the automatic injector shown in FIG. 1A. FIG. 2 shows an exploded view of an automatic injector shown in FIG. 1A & 1B.

According to FIG. 2, the automatic injectors utilize one or more biasing members, such as compression springs, to provide the force necessary to insert the needle into the user, push fluid from the drug chamber of the syringe cartridge out through the needle assembly for drug delivery, and activate a needle retraction safety mechanism. However, it is important to minimize the force necessary to be provided by such biasing members for various manufacturing and operational benefits. For example, a lower force biasing member, which may be more cost-effective than higher force biasing members, may be utilized if reduced forces are needed to perform all of the stages of device operation. Similarly, reducing necessary forces may enable the devices to be stored and transported more readily since the energy stored within the device prior to activation is reduced. Accordingly, the embodiments utilize novel plunger sub-assemblies which require lower forces to initiate activation of the retraction mechanism. Because the plunger sub-assemblies and the integrated retraction features are driven, or caused to activate, by the actuation mechanism, the actuation mechanisms and the automatic injectors may be configured to utilize lower force biasing members. Similarly, because the total force necessary to insert the needle into the user, deliver the drug fluid, and activate the needle retraction mechanism is reduced, a simplified actuation mechanism, such as an actuation mechanism having only one actuation pill and actuation spring, may be utilized to efficiently deliver all of the force necessary for the operation of the device. This advantage of the novel plunger sub-assemblies, and their integration into the actuation mechanism, provides substantial benefits to the manufacturability, stability, and operability of the novel automatic injectors.

We are experts in the field of precision drug delivery power springs, with decades of design and manufacturing experience, ensuring that for every critical infusion, our springs deliver unerringly accurate power.

Drug Delivery Component Solutions

Pumps (Syringe, Infusion, Insulin)

- Challenge: The drive mechanism needs to push the syringe plunger steadily and continuously, requiring the spring to maintain a constant force over long periods.

- Our Solution: We design and produce high-stability compression springs or constant-force springs for use in clutches, alarms, and drive arms, ensuring flow rate accuracy and device reliability.

Injection Pens

- Challenge: The dose-setting mechanism requires a spring (typically a torsion spring) to provide clear tactile detents and precise torque, while the injection button needs a compression spring with a comfortable feel.

- Our Solution: We provide micro torsion springs with precise torque values and long cycle lives, as well as compression springs with optimized force curves, to enhance the patient experience and dosage accuracy.

Auto-Injectors

- Challenge: This is one of the most demanding applications for a spring. After being stored under compression for years, the spring must instantly release tremendous energy to perform needle insertion and injection, with zero tolerance for failure.

- Our Solution: We use high-strength, creep-resistant specialty stainless steels or alloys and apply proprietary processes to manufacture high-energy storage power springs. We perform 100% force testing and rigorous life testing to ensure absolute reliability throughout the product’s shelf life.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | High-Strength Stainless Steel (e.g., 17-7PH, 302), Elgiloy®, MP35N® |

| Core Processes | High-Energy Spring Design, Heat Treatment, Pre-setting, 100% Force Inspection |

| Wire Diameter | 0.5mm – 3.0mm (0.020″ – 0.118″) |

| Outer Diameter | 3.0mm – 30mm (0.118″ – 1.181″) |

| Force Accuracy | As tight as ±3% |

| Shelf Life | Can be designed to meet storage requirements of several years |

| Cleanliness | Production and packaging in ISO Class 7/8 cleanrooms |

Core Performance Advantages

Ultimate Reliability & Safety

A zero-failure design and manufacturing philosophy, especially critical for single-use, life-saving devices.

Precise Force Output

Tight tolerance control ensures the accuracy of dosage and infusion rates.

Exceptional Fatigue Life

Guarantees consistent performance throughout the device’s designed lifecycle.

Excellent Creep Resistance

The spring experiences minimal force decay even after long-term storage under load.

.png)