– Guidewire Core Components: Navigating Precisely, Conquering Complexity

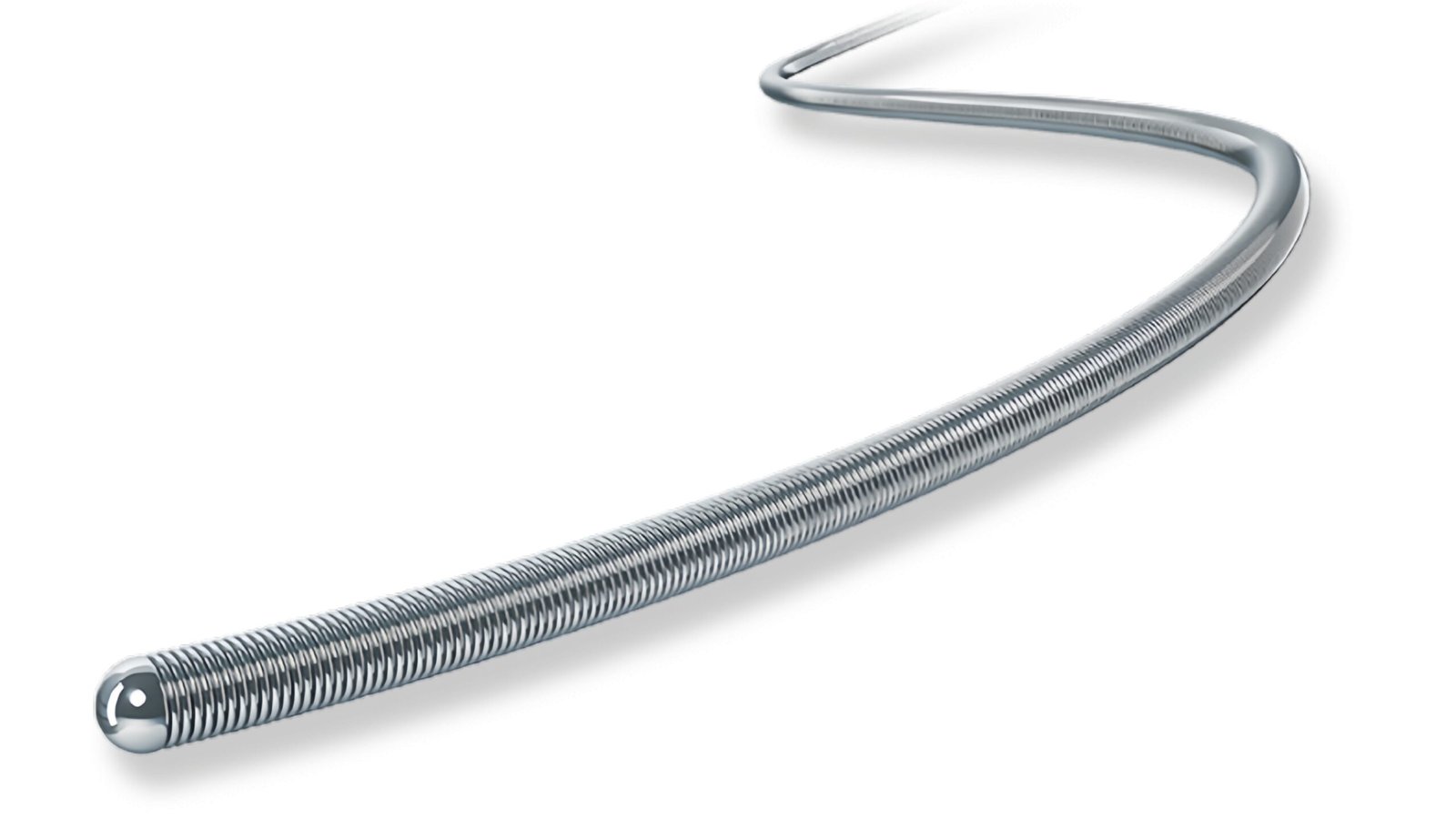

We provide global guidewire manufacturers with the core wire and coil components for superior torque response, exceptional kink resistance, and precise tip shaping, ensuring every navigation is accurate and safe.

Guidewire Technology Overview: The Vanguard of Interventional Therapy

The guidewire is the foundation of nearly every vascular and endoluminal intervention. It acts as a sophisticated “rail,” guiding balloons, stents, and catheters safely and accurately to the treatment site. A high-performance guidewire must strike a perfect balance between pushability, trackability, torque transmission, flexibility, and support. The heart of these demanding characteristics lies in the core components: precision-engineered metal wires and micro-coils.

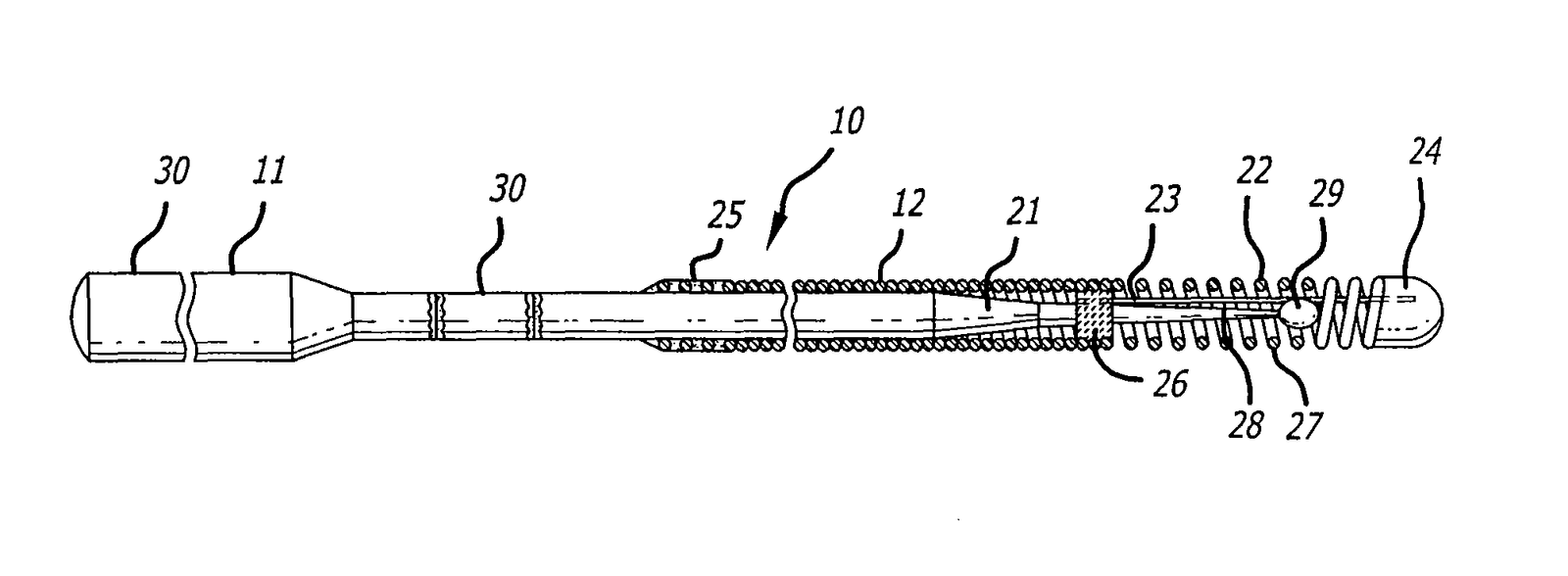

Figure on the left illustrates a guide wire 10 embodying features of the invention that is adapted to be inserted into a patient’s body lumen, such as an artery or vein. The guide wire 10 comprises an elongated, relatively high strength proximal core section 11, and a relatively short flexible distal core section 12. The distal core portion 12 has at least one tapered section 21 which becomes smaller in the distal direction. A helical coil 22 is disposed about the distal core section 12 and is secured by its distal end to the distal end of shaping ribbon 23 by a mass of solder which forms rounded plug 24 when it solidifies. The proximal end of the helical coil 22 is secured to the distal core section 12 at a proximal location 25 and at intermediate location 26 by a suitable solder. The proximal end of the shaping ribbon 23 is secured to the distal core portion 12 at the same intermediate location 26 by the solder. Preferably, the most distal section 27 of the helical coil 22 is made of radiopaque metal, such as platinum or platinum-nickel alloy, to facilitate the fluoroscopic observation thereof while it is disposed within a patient’s body. The most distal section 27 of the coil 22 should be stretched about 10 to about 30% in length to provide increased flexibility.

We understand the complexity and challenges of guidewire design. We don’t just supply components; we offer engineering solutions that integrate seamlessly with your R&D team to conquer every anatomical challenge, from coronary arteries to distal neurovasculature.

Guidewire Component Solutions

We provide customized core component solutions tailored to diverse clinical applications:

Puncture & Peripheral Guidewires

- Challenge: Require sufficient axial stiffness for tissue penetration, while the tip must be soft enough to prevent vessel trauma.

- Our Solution: We provide high-strength stainless steel core wires with a smooth stiffness transition achieved through precision centerless grinding. The distal tip can be welded with a highly radiopaque platinum-iridium coil, perfecting the balance between pushability and safety.

Coronary Artery Guidewires

- Challenge: Extremely tortuous and narrow vessels demand 1:1 torque transmission, excellent trackability, and tactile feedback from the tip.

- Our Solution: We utilize high-elasticity, high-strength core materials combined with variable-pitch micro-coiling technology to optimize tip flexibility. Hydrophilic/hydrophobic coatings can be applied to significantly reduce friction and enhance maneuverability.

Neurovascular Guidewires

- Challenge: The neurovasculature is incredibly delicate, demanding atraumatic, exceptionally flexible wires with outstanding shaping and shape retention capabilities.

- Our Solution: We use superelastic Nitinol or composite wires and offer steam-shaping processes, allowing physicians to shape the distal tip to any desired angle for navigating the complex intracranial vessel network.

Urological, GI & Airway Guidewires

- Challenge: Require robust support to guide endoscopes or other devices, coupled with excellent kink resistance.

- Our Solution: We offer large-diameter, high-support stainless steel or Nitinol guidewire components, which can be integrated with a PTFE coating to ensure smooth device exchange.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | Platinum-Iridium (Pt-Ir), 316LVM Stainless Steel, Tungsten/W-Rhenium (W/W-Re), Gold (Au) |

| Core Processes | Multi-taper Centerless Grinding, Variable-Pitch Micro-Coiling, Laser Welding, Steam Shaping, PTFE/Hydrophilic Coating |

| Wire Diameter | 0.02mm – 0.15mm (0.0008″ – 0.006″) |

| Outer Diameter | 0.02mm – 0.15mm (0.0008″ – 0.006″) |

| Pitch | Variable pitch capable, tol. ±0.01mm |

| Surface Treatment | Electropolishing, PTFE Coating, Hydrophilic/Hydrophobic Coating |

Core Performance Advantages

Superior Torquability

Ensures every subtle rotation at the proximal end is transmitted precisely to the distal tip.

Excellent Trackability

The guidewire tip follows the natural path of the vessel, easily navigating tortuous anatomy.

Optimized Flexibility Profile

A seamless transition from a stiff shaft to a soft tip, achieved through multi-taper grinding and variable-pitch coil designs.

High Radiopacity

Distal markers made from platinum-iridium, tungsten, or gold ensure clear visibility under fluoroscopy for precise positioning.

Kink Resistance

High-elasticity materials and optimized structures prevent the wire from kinking during complex maneuvers.

.png)