– The Core of Endoscope Control: A Flexible Vision, A Precise Exploration

We provide high-precision bending section coils, pull wires, and related components for advanced flexible endoscopes, enabling smooth, precise angulation control that extends the physician’s vision deep inside the human body.

Endoscope Technology Overview: The “Eyes” of Minimally Invasive Medicine

Endoscopes, particularly flexible endoscopes, are an indispensable diagnostic and therapeutic platform in modern medicine. They can navigate natural orifices like the GI and respiratory tracts, allowing physicians to directly visualize and operate on lesions. One of its most critical technologies is the articulation of the distal tip—the physician manipulates a control knob, which pulls internal wires, causing the “bending section” (composed of precision coil pipes) to deflect in four directions (up, down, left, right) for panoramic observation.

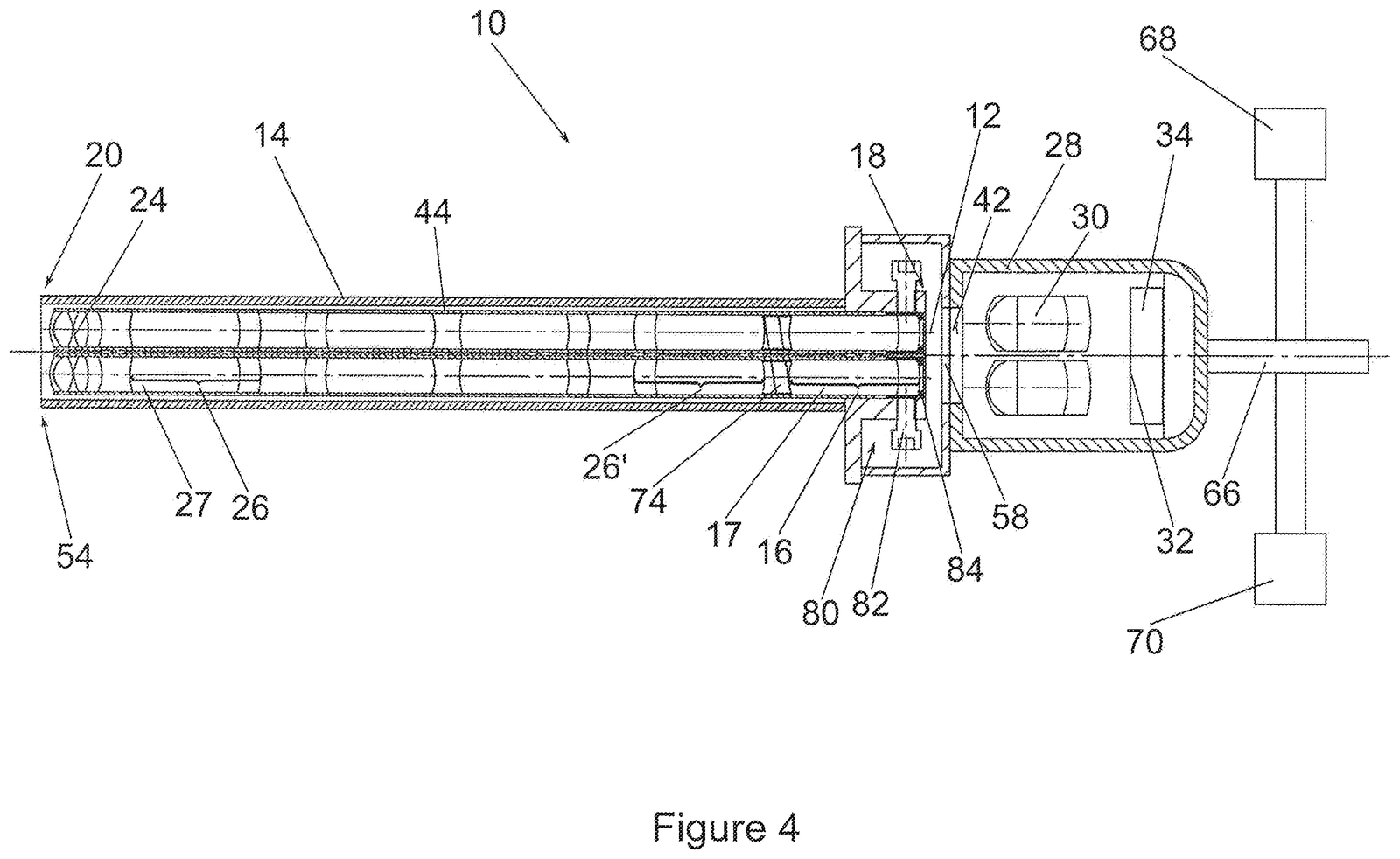

FIG. 4 shows a schematic illustration of a exemplary embodiment of a video endoscopic device 10 with a mechanical spring 74 for setting an axial distance between the successive optical components 26′ and 16. Instead of the mechanical spring 74, use can also be made of e.g. a gas spring or a different resilience element. A combination of the mechanical spring 74 with a different resilience element, for example a gas mixture, a gas, a liquid or a solid, is also conceivable. In the shown exemplary embodiment, the mechanical spring 74 is arranged in an air atmosphere, i.e. in a gas mixture. The mechanical spring 74 serves to set an axial distance between the two successive optical components 26′ and 16 such that mechanical play between the components is prevented. Here, mechanical play is prevented, or at least reduced, by the spring effect of the mechanical spring 74. It is also possible for a plurality of mechanical springs 74 or combinations of resilience elements to be arranged between a plurality of successive optical components along the endoscope shaft, for example between all optical components of a respective parallel arrangement.

This complex mechanical structure demands extreme precision, component synergy, and reliability. We are a leading manufacturer of the core components in this field, dedicated to providing a smoother, more precise control experience for the next generation of HD and therapeutic endoscopes.

Endoscope Component Solutions

Flexible Endoscopes

- Challenge: The “bending section” is composed of hundreds of precisely machined coil segments articulated together. It must be both flexible and stable, and the pull wires must glide smoothly within a minimal space.

- Our Solution: We produce precision coil pipes from stainless steel or titanium alloys with an extremely high surface finish on both the inner and outer diameters, ensuring low-friction transmission for the pull wires. We also supply the matching high-strength, low-elongation tungsten or stainless steel angulation wires.

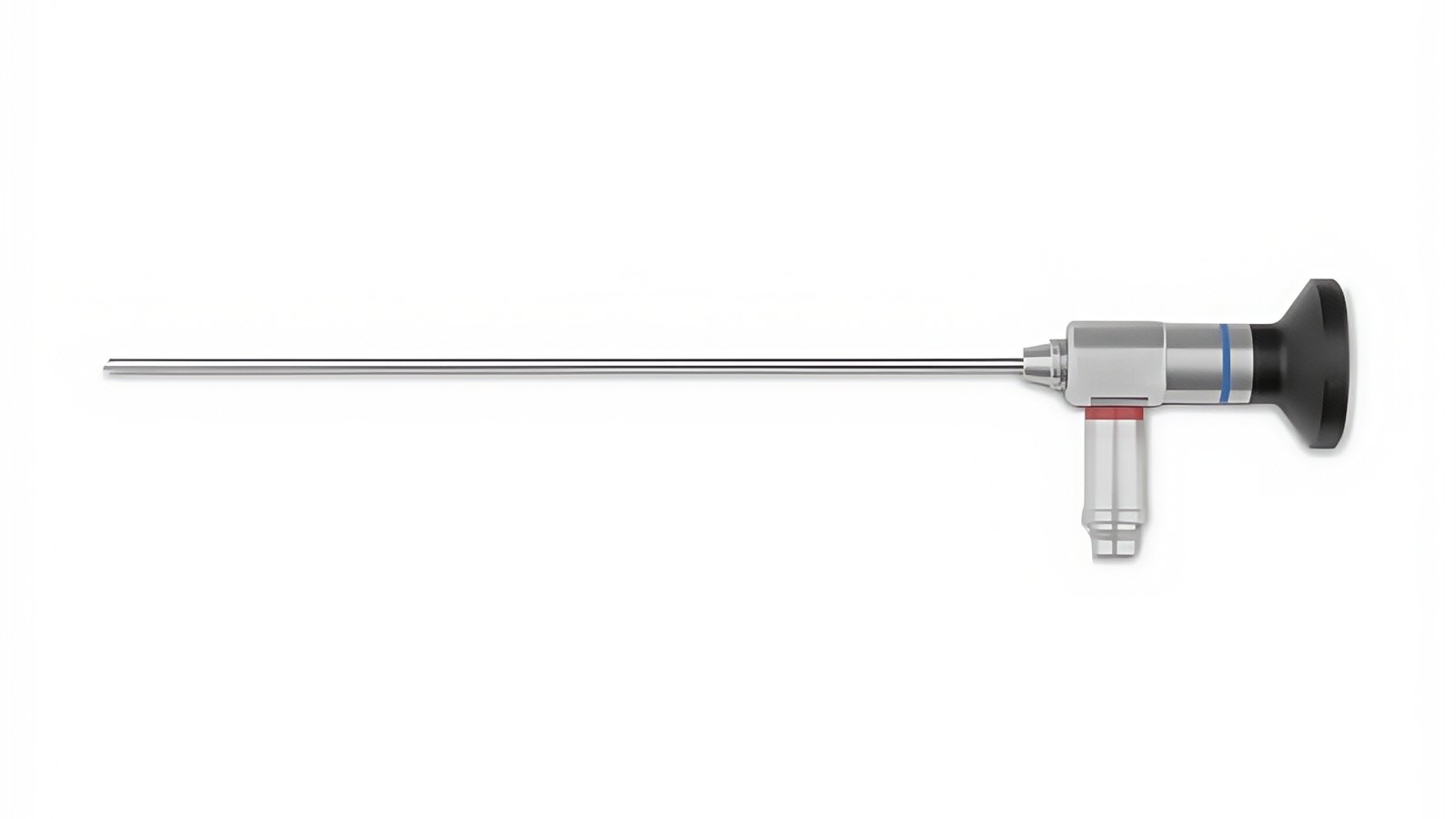

Rigid Endoscopes

- Challenge: Although the scope body is rigid, certain mechanical components within its optical or instrument channels still require springs for support, reset, or shock absorption.

- Our Solution: We provide a variety of custom micro-springs and wire forms for fixing lens assemblies or controlling valves in the instrument channel.

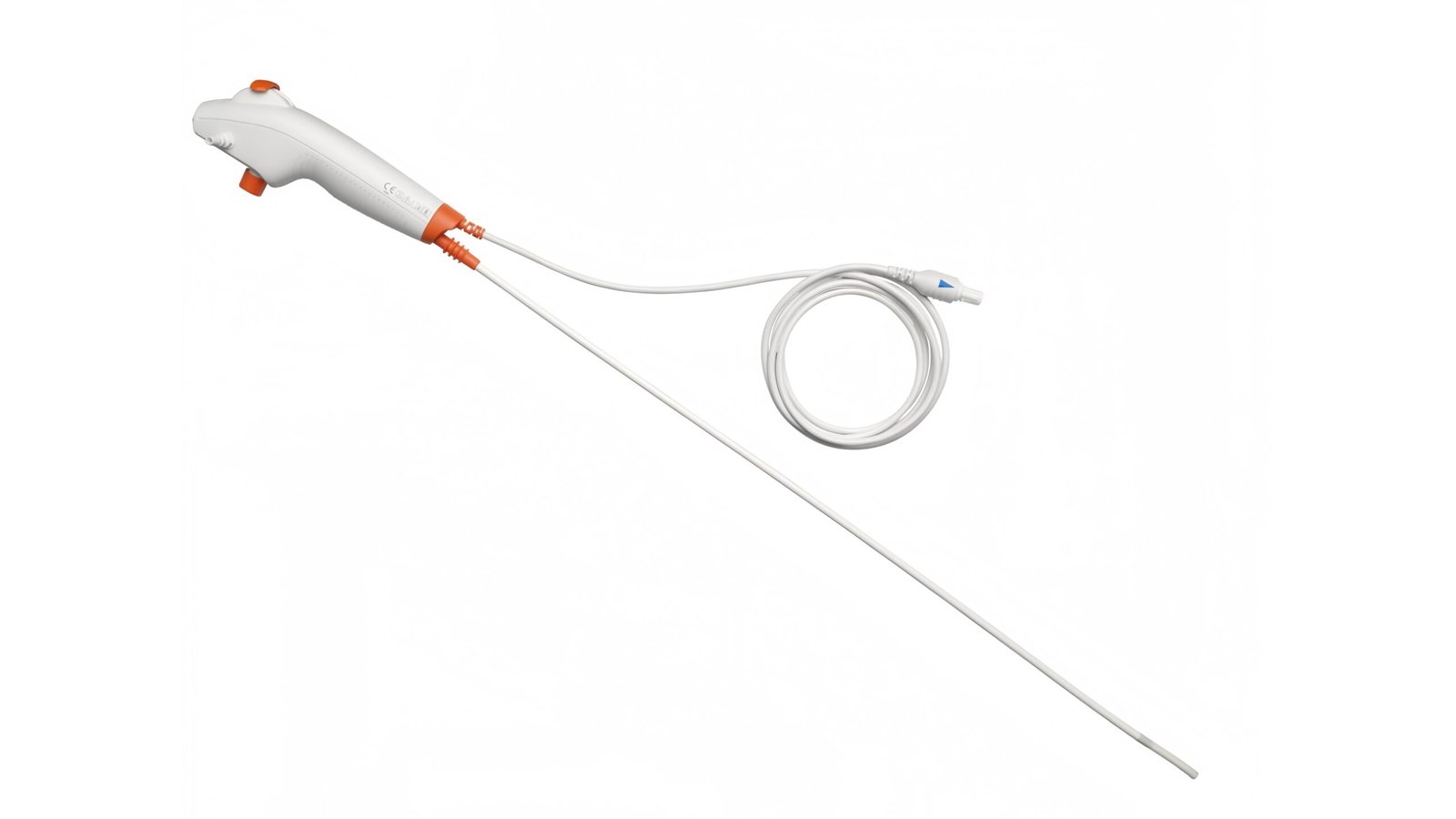

Disposable Endoscopes

- Challenge: To maintain the reliability of core functions like angulation while under strict cost controls.

- Our Solution: Through optimized designs and efficient automated production, we offer highly cost-effective bending section coils and components. We can work with you to develop the most economical solution.

_副本-scaled.jpg)

Endoscopic Ultrasound (EUS)

- Challenge: In addition to angulation, this requires stable support and precise positional control for the ultrasound transducer at the tip.

- Our Solution: We provide reinforced coil pipes with higher stiffness and precision to ensure image stability during ultrasound scanning.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | 304/316L Stainless Steel, Titanium Alloys |

| Core Processes | Precision Coil Winding, Ultrasonic Cleaning, Laser End-Finishing, Pull Wire Tip Fusing |

| Wire Diameter | 0.2mm – 1.5mm (0.0079″ – 0.0591″) |

| Outer Diameter | 1.5mm – 15mm (0.059″ – 0.591″) |

| ID/OD Surface Finish | Can achieve a mirror-like finish to significantly reduce friction |

| Component Integration | Pre-assembled bending section assemblies available upon request |

Core Performance Advantages

Smooth Angulation

Precision component mating ensures articulation is free of jamming and highly responsive.

Precise Angle Control

Low-elongation pull wires and a stable bending structure ensure angulation is accurate and repeatable.

High Durability

Components are built to withstand repeated bending cycles and rigorous cleaning and disinfection protocols.

Low-Friction Transmission

Ultra-smooth inner coil walls and wire surfaces minimize the loss of control force.

.png)