– Drive Springs for Medical Clips: Engineering Unyielding Closure

We provide the world’s leading medical clip manufacturers with micro-actuation springs of ultra-high reliability and precise clamping force, ensuring every closure in critical applications like hemostasis, anastomosis, and tissue marking is precise, durable, and secure.

Medical Clip Technology Overview: The Ultimate Safety Lock in Minimally Invasive Surgery

In endoscopic surgery, the medical clip is an indispensable tool for physicians to perform hemostasis, close perforations, mark lesions, and assist in anastomosis. The success of a medical clip hinges on its ability to be deployed accurately within a narrow field of view and subsequently provide a strong, stable, and durable closing force. The “engine” behind this closing force is its intricately designed internal drive spring. The performance of this spring directly dictates the success or failure of the clip, impacting surgical outcomes and patient safety.

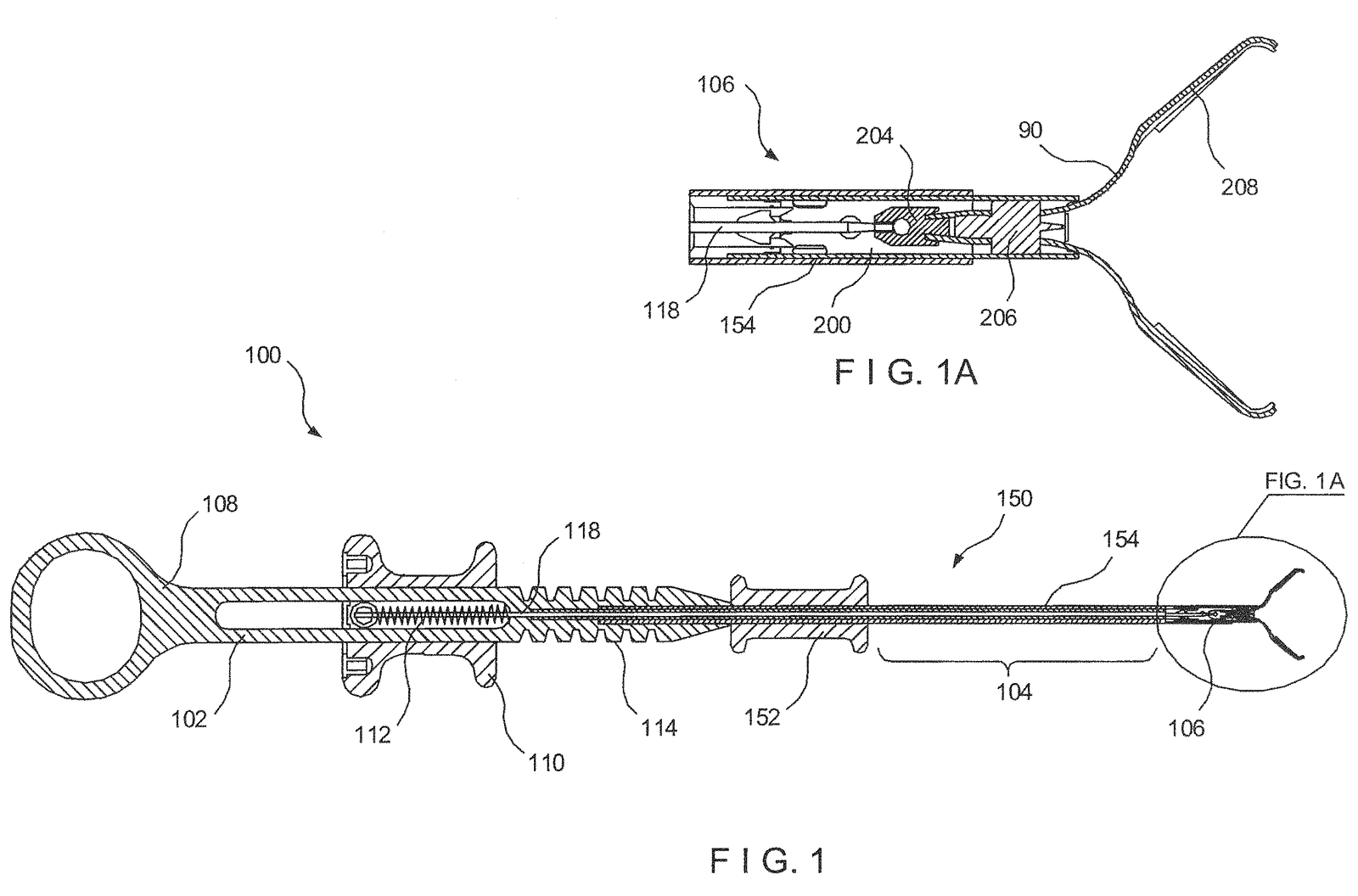

FIG. 1 shows a side elevation view of a through the scope hemostatic clipping device according to an exemplary embodiment. This device is a hand operated tool that is used to insert a hemostatic clip through an endoscope lumen, position the clip over a wound, clamp it and deploy it over the affected tissue. The tool is further designed to release the hemostatic clip once it has been clamped in place, and to be withdrawn through the endoscope. To more clearly explain the operation and construction of the exemplary device, it may be divided into three principal components. As shown in FIG. 1, the hemostatic clipping device 100 comprises a handle assembly 102, a shaft section 104, and a clip assembly 106. A detailed view of the clip assembly 106 is shown FIG. 1A.

As shown in FIGS. 1, a sliding spool 110 is mounted on the handle body 108 so that it can slide along a slot 116, which maintains its position within the handle assembly 102. Because the sliding spool 110 is connected to the control wire 118, the user may manipulate the control wire 118 by grasping the handle body 108 and moving the sliding spool 110 along the slot 116. A return spring 112 may be provided within the handle body 108 to bias the sliding spool 110, and thus the control wire 118 toward a desired position. In the present embodiment, the sliding spool 110 is biased to the proximal position. The handle assembly 102 may also include a connection portion 114, which receives the control wire 118 and attaches the shaft section 104 to the handle assembly 102.

As experts in medical-grade micro-springs, we deeply understand the decisive importance of the drive spring to a medical clip. We are committed to providing the most reliable power core for your product, ensuring it delivers trustworthy performance when it is needed most.

Medical Clip Spring Solutions

Hemostatic & Anastomosis Clips

- Challenge: Require a strong and durable tissue compression force after deployment to effectively stop bleeding or ensure the healing of an anastomotic site. This demands exceptional fatigue and creep resistance from the spring.

- Our Solution: We design and manufacture high-energy-storage, high-fatigue-resistance micro torsion or compression springs. We select materials with outstanding biocompatibility, such as cobalt-chrome alloys (MP35N®) or specialty stainless steels, to ensure the clip maintains a stable clamping force throughout the entire healing period.

Tissue Clips

- Challenge: Often used for closing smaller wounds or marking tumor locations, requiring a moderate clamping force that is effective for tissue apposition without causing excessive trauma.

- Our Solution: We provide custom springs with precise force values and sensitive response. We can collaborate with your R&D team, using Finite Element Analysis (FEA) to accurately simulate and optimize the spring’s structure, achieving your ideal mechanical curve and handling characteristics.

Endoscopic Clips

- Challenge: The overall structure must be compact, requiring the spring to exert maximum force within a minimal space. The material must also withstand rigorous sterilization processes.

- Our Solution: We focus on miniaturized designs, producing precision springs with extremely tight tolerances on diameter and length. All products can be manufactured and packaged in our ISO Class 7/8 cleanrooms to ensure the highest level of cleanliness and biological safety.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | 316LVM Stainless Steel, Titanium Alloys, MP35N® |

| Core Processes | Micro-Spring Precision Coiling, Finite Element Analysis (FEA), Heat Treatment, Mechanical Force Testing, Cleanroom Packaging |

| Wire Diameter | 0.05mm – 0.5mm (0.002″ – 0.020″) |

| Outer Diameter | 0.3mm – 3.0mm (0.012″ – 0.118″) |

| Force Control Tolerance | As tight as ±5% |

| Cleanliness | ISO Class 7 / 8 (Class 10,000 / 100,000) |

Core Performance Advantages

Precise & Durable Clamping Force

Springs undergo proprietary processes to ensure force accuracy and minimal decay during long-term implantation.

Excellent Biocompatibility

All materials comply with medical implant standards such as ASTM F562 and ASTM F138, ensuring patient safety.

High Fatigue Resistance

Guarantees stable performance in dynamic environments subject to vascular pulsation or tissue movement.

Designed for Automation

High dimensional consistency of our springs makes them ideal for high-speed automated assembly lines.

.png)