– Catheter Reinforcement Cores: The Golden Skeleton for Superior Performance

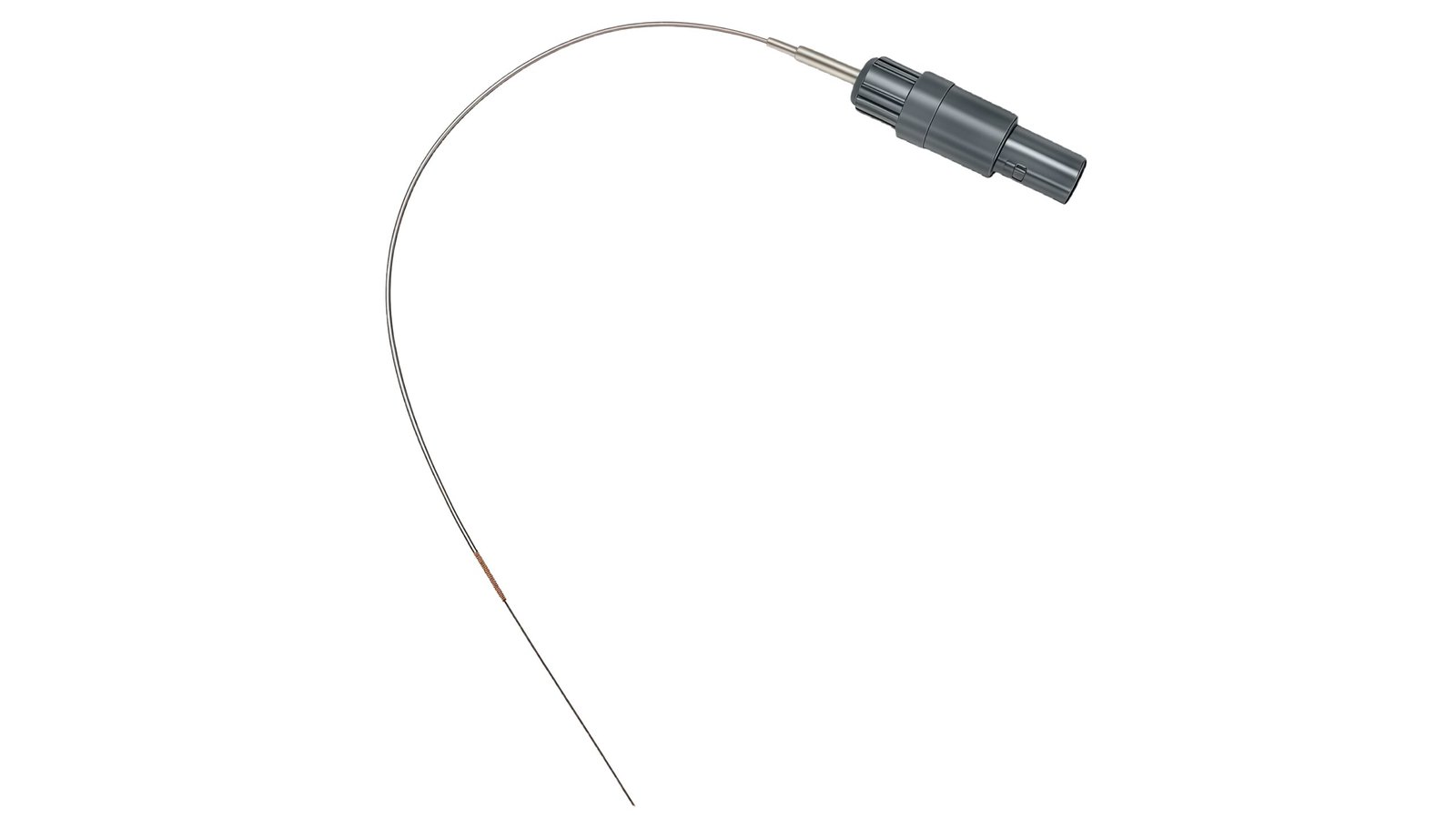

We provide high-precision reinforcement coils and profile wires for a full range of interventional and delivery catheters, dramatically improving pushability, crush resistance, and torque control.

Catheter Technology Overview: The Lifeline for Precision Delivery

Catheters are the cornerstone of modern minimally invasive medicine, performing critical tasks such as contrast agent delivery, balloon angioplasty, stent deployment, and electrophysiological mapping. A high-performance catheter must offer excellent pushability (transmitting force efficiently to the distal end) and trackability (navigating complex anatomy) while maintaining lumen integrity. To prevent the soft catheter body from kinking or collapsing during delivery, embedding a precision metal reinforcement component within the wall has become the industry standard.

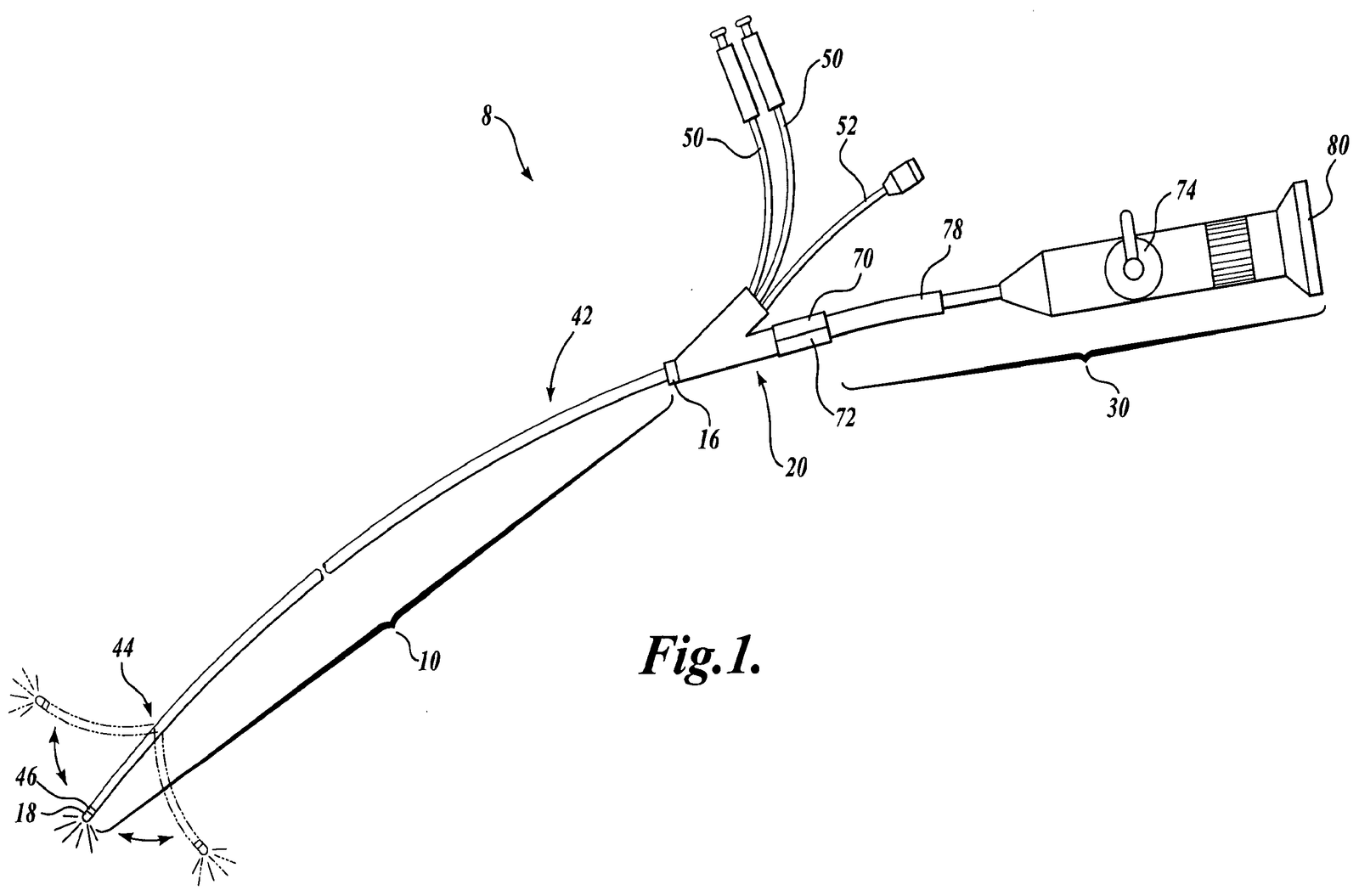

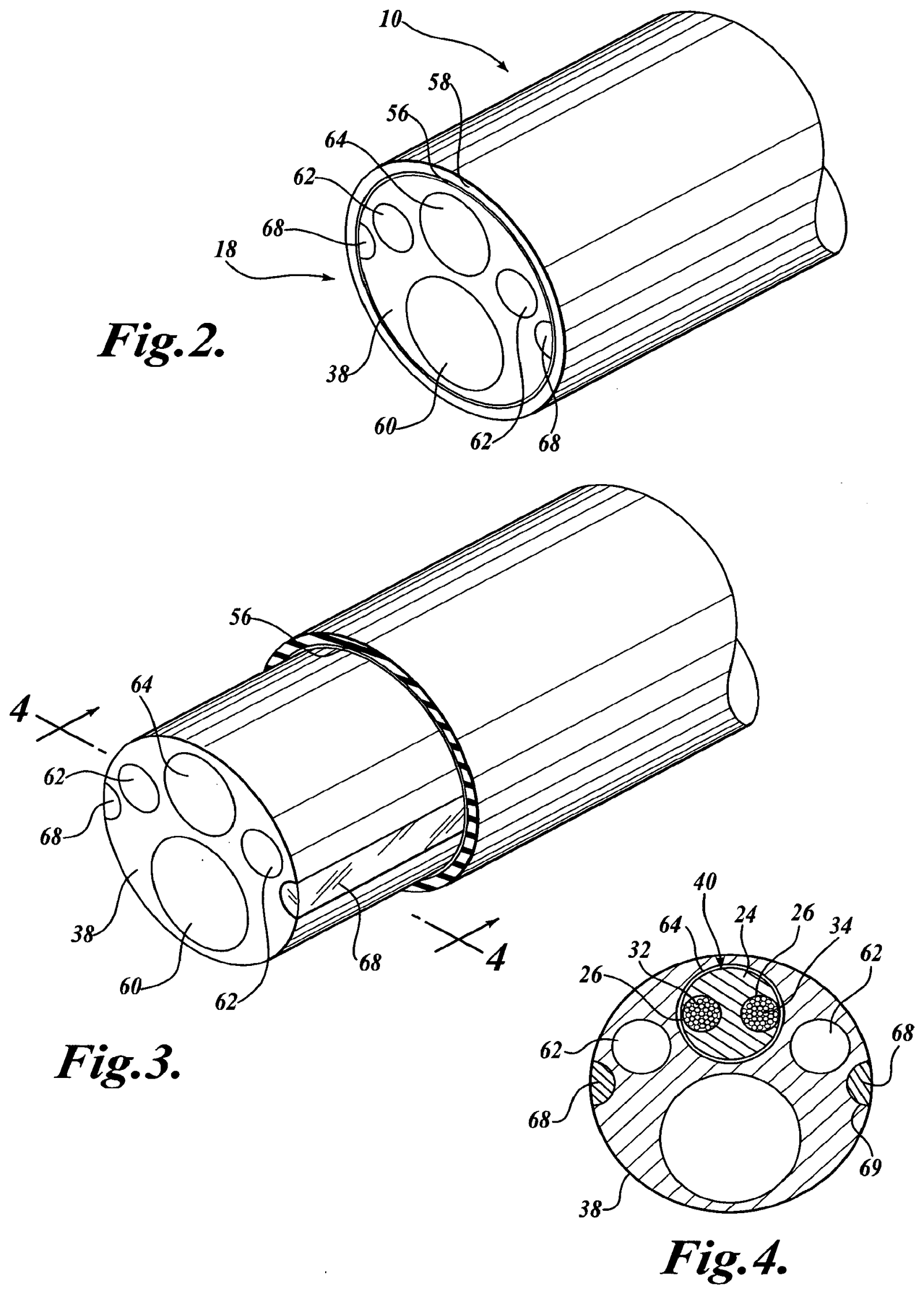

FIG. 1 is an assembly view of an optical catheter system according to one embodiment. Referring to FIGS. 2-4, the elongated body 38 of the catheter 10 defines a working channel 60 that extends the entire length of the catheter and allows for the passage of various treatment or diagnostic devices, such as guide wires, stone retrieval baskets, lasers, biopsy forceps etc. The working channel 60 preferably has a diameter sufficient to accept up to a 4 French working device, such as a retrieval basket device or biopsy forceps. The elongated body 38 of the catheter 10 may also include additional channels 62, for use, e.g., as irrigation/insufflation channels or additional working channels for one or more of the instruments mentioned above. The channels 62 each extend the entire length of the catheter 10 and, like the working channel 60, allow the passage of devices, liquids and/or gases to and from the treatment area. The channels 62 each have a diameter similar to or smaller than main working channel 60. In one embodiment, the channels 62 each have a diameter of about 0.020 inches. The catheter may also include a channel 64 that extends the entire length of the catheter through which a fiberscope, fiber optic cables or other small diameter imaging devices (e.g., 0.25 mm-1.5 mm diameter) can be routed to the distal end of the catheter 10. It will be appreciated that one or more of the channels 62 may be eliminated or dimensioned to accommodate the necessary diameter needed for the working channel 60 and optic lumen.

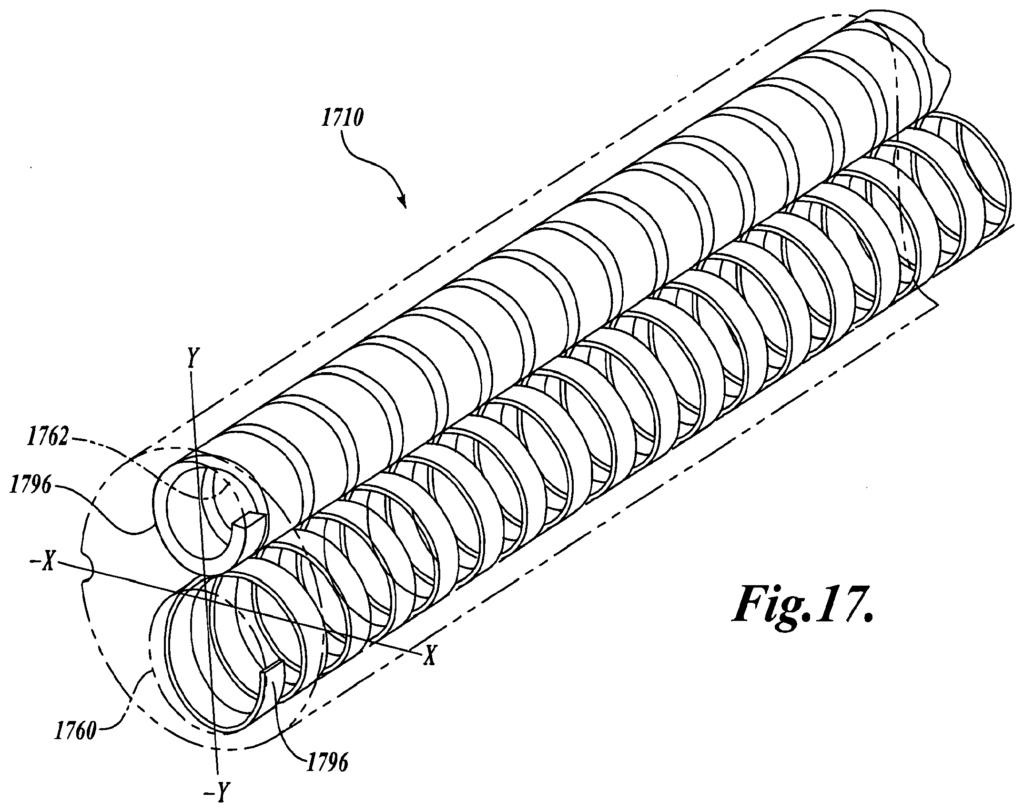

FIG. 17 illustrates another embodiment of a catheter 1710 having a deflectable distal portion. In this embodiment, the catheter is constructed from a very flexible plastic extrusion with multiple lumens. The two main lumens, the working channel 1760 and the optical assembly channel 1762, are reinforced with coils 1796 to minimize out-of plane deflection. As shown in FIG. 17, the center of both lumens and both coils lie on the Y-axis to provide less resistance against deflection in the x-plane. When the steering wires (not shown) are pulled along the direction of the steering wire slots, the catheter will tend to bend about the y-axis or in the×plane. The coils 1796 also prevent the lumen from kinking as the catheter deflection radius becomes tighter. The catheter 1710 may further include an outer braid and outer layer, as described in detail above.

We are experts in catheter reinforcement technology, with a deep understanding of the nuanced performance differences required by various catheter types. We offer a range of reinforcement solutions, from standard round wire to high-torque flat wire, to help your catheter products outperform the competition.

Catheter Component Solutions

Reinforced Catheters

- Challenge: To maximize kink and crush resistance while maintaining flexibility.

- Our Solution: We provide round stainless steel or Nitinol reinforcement coils with precise pitch control. Variable-pitch designs can be implemented to make the catheter progressively more flexible towards the distal tip, optimizing overall handling.

Delivery Systems

- Challenge: Delivering large devices like stents or heart valves requires extreme support and pushability, while maximizing the inner lumen diameter without compression.

- Our Solution: We utilize high-strength flat or square wire to form the reinforcement coil. Compared to round wire, this provides a larger inner lumen and superior crush resistance for the same outer diameter.

Drainage Catheters

- Challenge: Require exceptional flexibility and anti-kink properties to ensure unimpeded drainage.

- Our Solution: An open-pitch coil design provides the necessary radial support while endowing the catheter with maximum flexibility.

Electrophysiology (EP) Catheters

- Challenge: Require precise distal tip deflection and 1:1 torque transmission for accurate mapping and ablation inside the heart.

- Our Solution: We utilize flat wire or multi-filar braided structures with high torque transmission efficiency. We can also integrate custom features like pull-wire channels to provide a solid foundation for precise, “on-target” therapy.

Technical Specifications & Capabilities

| Parameter | Specification & Capability |

| Materials | 304/316L Stainless Steel, Nitinol |

| Core Processes | Precision Coiling (Round/Flat/Square Wire), Variable-Pitch Control, Laser End-Finishing |

| Wire Profile | Round, Flat, Square, Custom Shapes |

| Wire Diameter | 0.1mm – 0.8mm (0.0039″ – 0.0315″) |

| Outer Diameter | 0.5mm – 10mm (0.020″ – 0.394″) |

| Pitch Control | Closed Pitch, Open Pitch, Variable Pitch |

| Surface Treatment | Passivation, Cleaning (Oil-Free) |

Core Performance Advantages

Enhanced Pushability

The robust metal skeleton efficiently transfers force from the hub to the catheter tip.

Superior Crush Resistance

Guarantees lumen integrity under vascular pressure or during device interaction.

Precise Torque Control

Enables synchronous rotation between the proximal and distal ends for accurate positioning.

Customizable Flexibility

Achieve the optimal flexibility profile for different sections of the catheter through variable-pitch and variable-wire-profile designs.

.png)