At ZW Precision Hardware, we recognize Prototyping & Testing as a crucial phase within the precision manufacturing process to guarantee exceptional product performance and quality.

Prototype Manufacturing and Testing Processes

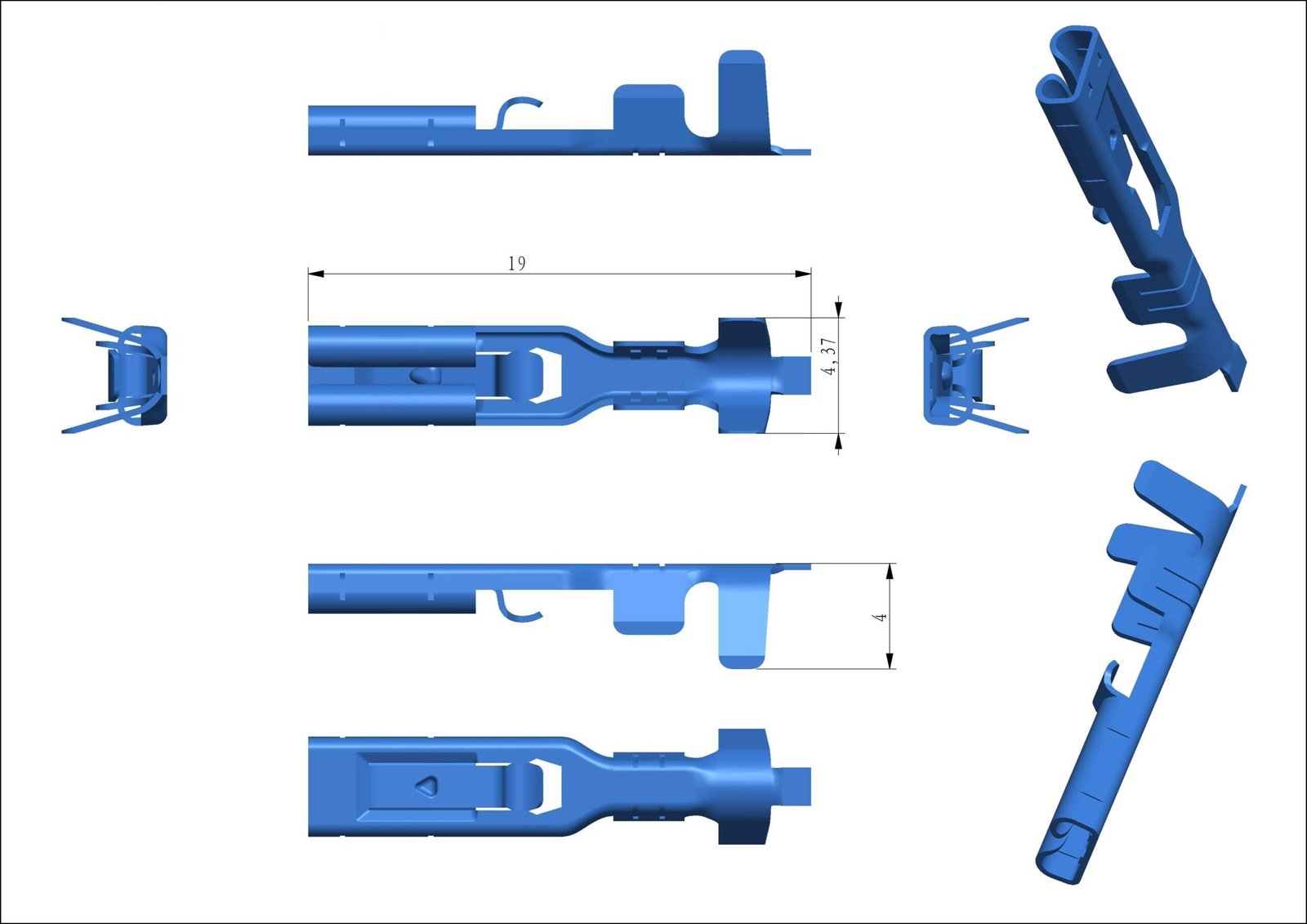

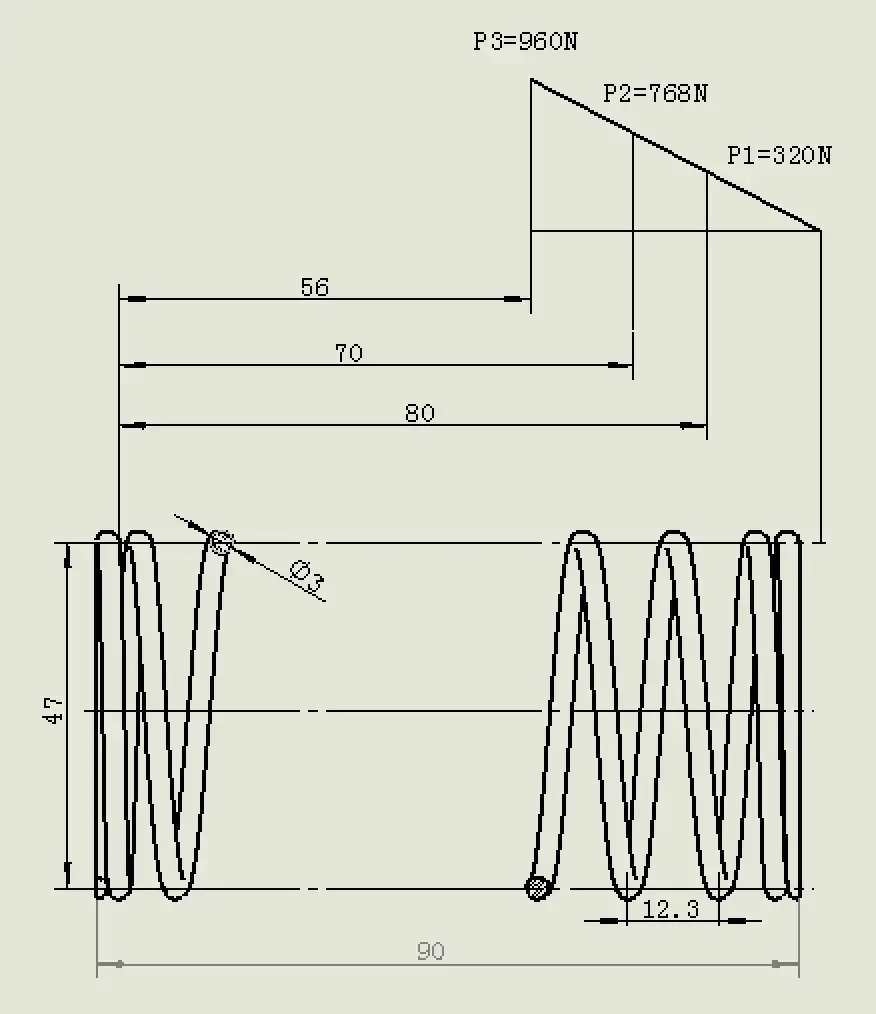

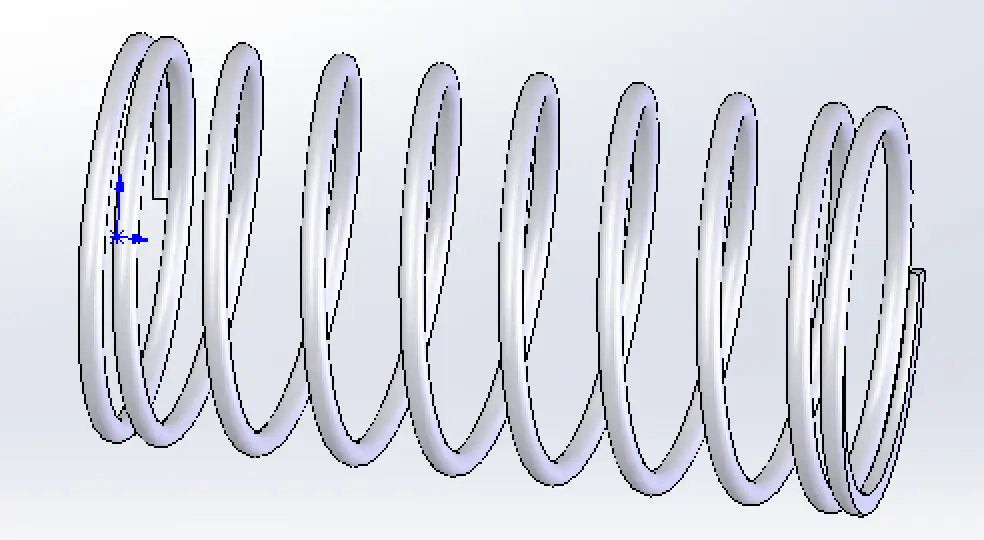

Our comprehensive prototype development services span from initial concept validation through pre-production stages, empowering customers to refine designs, enhance product reliability and accelerate their time to market. We employ advanced manufacturing techniques including CNC machining, 3D printing, wire forming, stamping and spring forming to rapidly produce intricate and precise components. Our robust testing protocols, such as load testing, fatigue testing and environmental simulations, ensure products deliver reliable and outstanding performance, even under demanding conditions.

Applications and Quality

Our skilled engineering team closely collaborates with clients, providing customized design optimization recommendations to align prototypes perfectly with final application requirements and industry standards. Whether your projects involve springs, wire forms, pressings or stampings, our prototyping and testing services help minimize developmental risks, enhance product quality and facilitate seamless transitions into efficient full-scale production.

.png)