In demanding industrial environments, mechanical stability and durability are the cornerstones of success. Our line of precision Industrial springs is engineered to deliver unparalleled reliability and performance in a wide range of high-load, high-frequency, and critical industrial applications. From trigger springs in actuating mechanisms and valve springs in fluid control systems to lock springs that ensure safety, each product is tasked with the core mission of guaranteeing precise equipment operation and extending service life.

ZW Precision Hardware has a profound understanding of the extreme requirements that industrial applications place on spring force accuracy, fatigue resistance, corrosion resistance, and temperature tolerance. Therefore, we select the most robust alloy materials, combining them with advanced heat treatment and surface finishing processes, to ensure our springs exhibit superior elasticity and lasting power even under the harshest working conditions. Choosing our Precision Industrial Springs is choosing an unwavering commitment to the quality and performance of your products.

Our Core Competencies

Our Typical Products Specifications

Trigger Springs

Trigger springs are the core power components within various trigger mechanisms, widely used in power tools, industrial spray guns, dispensers, and even precision devices in the defense industry. They must provide an extremely stable and consistent force feedback to ensure every operation has an identical feel and response speed, all while possessing an exceptionally high fatigue life.

| Spring Type | Precision Compression Springs, Torsion Springs, Double Torsion Springs, Custom Leaf Springs |

| Technical Parameters | Wire diameter: 0.1mm – 3.0mm. Force Tolerance: ±5% to ±10% to ensure operational consistency. Cycle Life: 100,000 to over 1,000,000 cycles to meet high-intensity use requirements. Force-Travel Curve: Can be designed to be linear or with a specific tactile profile based on requirements. Response Speed: Optimized geometric design ensures rapid recoil and reset. |

| Material Characteristics | Stainless Steel (SUS302/304/17-7PH): The preferred material, offering an excellent combination of corrosion resistance and high fatigue strength. Music Wire: Extremely high strength, suitable for dry or well-protected internal environments. High Carbon Steel: Cost-effective and capable of achieving high hardness and strength through heat treatment. |

| Surface Treatment | Black Oxide: Provides basic corrosion resistance and reduces reflectivity. Zinc Plating: Offers excellent corrosion protection and is cost-effective. Mechanical Polish/Passivation: Removes surface burrs, improving fatigue life and the corrosion resistance of stainless steel. |

| Heat Treatment | Stress Relieving: A critical process to eliminate internal stresses from forming and stabilize the spring’s mechanical properties. Quenching & Tempering: Used for high-carbon and alloy steels to achieve an ideal combination of high strength and toughness. |

Lock Springs

Lock springs are critical to the safety and reliability of all types of locks, including door locks, padlocks, automotive locks, and safes. They provide the necessary push, pull, or torsional force within lock cylinders, latch bolts, and handle mechanisms. They must reset precisely over long-term use and in various environments, as any failure could lead to serious security issues.

| Spring Type | Torsion Springs, Micro Extension Springs, Compression Springs, Wire Forms |

| Technical Parameters | Wire Diameter: 0.1mm – 3.0mm. Dimensional Accuracy: High precision to ensure smooth operation within tight lock bodies. Corrosion Resistance: Must be able to resist moisture, salt spray, and other environmental factors. Fatigue Life: Meets industry standards for tens of thousands of open/close cycles. |

| Material Characteristics | Stainless Steel (SUS302/304): The most common material for modern lock springs due to its superior corrosion resistance and strength. Phosphor Bronze: Good corrosion resistance and non-magnetic properties, suitable for certain specialty locks. Music Wire: High strength and low cost, but requires a reliable surface treatment to prevent rust. |

| Surface Treatment | Nickel Plating: Provides a clean finish and good corrosion resistance. Zinc Plating: Excellent rust prevention, especially for non-stainless steel materials. Passivation: Enhances the natural protective layer of stainless steel; a standard finish for high-quality lock springs. |

| Heat Treatment | Stress Relieving: An essential process for all lock springs to guarantee lasting and stable elastic force. Austempering: Provides superior toughness and fatigue life to prevent brittle spring failure. |

Spout Springs

Spout springs are primarily used in various fluid dispensers, such as liquid soap bottles, lotion pumps, and industrial oil cans. It acts as a return element, pushing the pump head or valve back to its original position after being pressed, readying it for the next actuation. These springs must resist chemical corrosion from the liquids they contact and provide just the right amount of return force.

| Spring Type | Micro Compression Springs |

| Technical Parameters | Wire diameter: 0.1mm – 1.5mm. Return Force: Precisely designed to overcome liquid viscosity and ensure a full reset. Chemical Compatibility: A core requirement; must be compatible with contact liquids (e.g., soap, alcohol, oils). Pitch Control: Uniform pitch ensures linear compression characteristics. |

| Material Characteristics | Stainless Steel (SUS304/316): The preferred and most common material. SUS316, containing molybdenum, offers enhanced resistance to chlorides and chemicals, making it the hallmark of a high-quality spout spring. Music Wire: High strength and low cost, but requires a reliable surface treatment to prevent rust. |

| Surface Treatment | Generally No Additional Treatment: Corrosion-resistant materials are used directly. Passivation: For stainless steel, this maximizes its resistance to chemical corrosion. |

| Heat Treatment | Stress Relieving: Performed in a controlled atmosphere to prevent changes to surface properties and to stabilize the spring force. |

Clamp Springs

Clamp springs are the core power source for a wide variety of industrial clamps, pipe clamps, hose clamps, and fixturing devices. They can be powerful torsion springs or heavy-duty compression springs, designed to provide a massive and continuous clamping force to ensure workpieces, pipes, or other components are held securely.

| Spring Type | Heavy-Duty Torsion Springs, Large Wire Diameter Compression Springs, Rectangular Wire Springs |

| Technical Parameters | Wire Diameter / Material Thickness: Typically thick, from 0.5mm to 5mm or more. Force / Torque Output: A key parameter, ranging from a few Newtons to thousands of Newtons depending on clamping needs. Working Angle / Travel: Designed according to the opening range of the clamp. Durability: Must be able to withstand repetitive loading and harsh industrial environments. |

| Material Characteristics | High Carbon Steel (65Mn/72A): Cost-effective and capable of achieving very high strength through heat treatment. Alloy Steel (60Si2Mn/55CrSi): Fortified with elements like chrome and silicon for higher strength, hardenability, and tempering stability. Suitable for the highest load applications. Stainless Steel (SUS304/316): Combines corrosion resistance, temperature resistance, and stable mechanical properties. |

| Surface Treatment | Zinc Plating / Chrome Plating: Provides excellent rust and wear resistance. Coating / Powder Coating: Provides a thicker protective layer, available in different colors, and further enhances corrosion resistance. Black Oxide: An economical anti-rust option, often used in oily environments. |

| Heat Treatment | Quenching & Tempering: Imparts high strength and load-bearing capacity to the spring. Shot Peening: Creates a layer of compressive stress on the spring’s surface, significantly increasing fatigue strength and life. This is a critical process for high-load springs. |

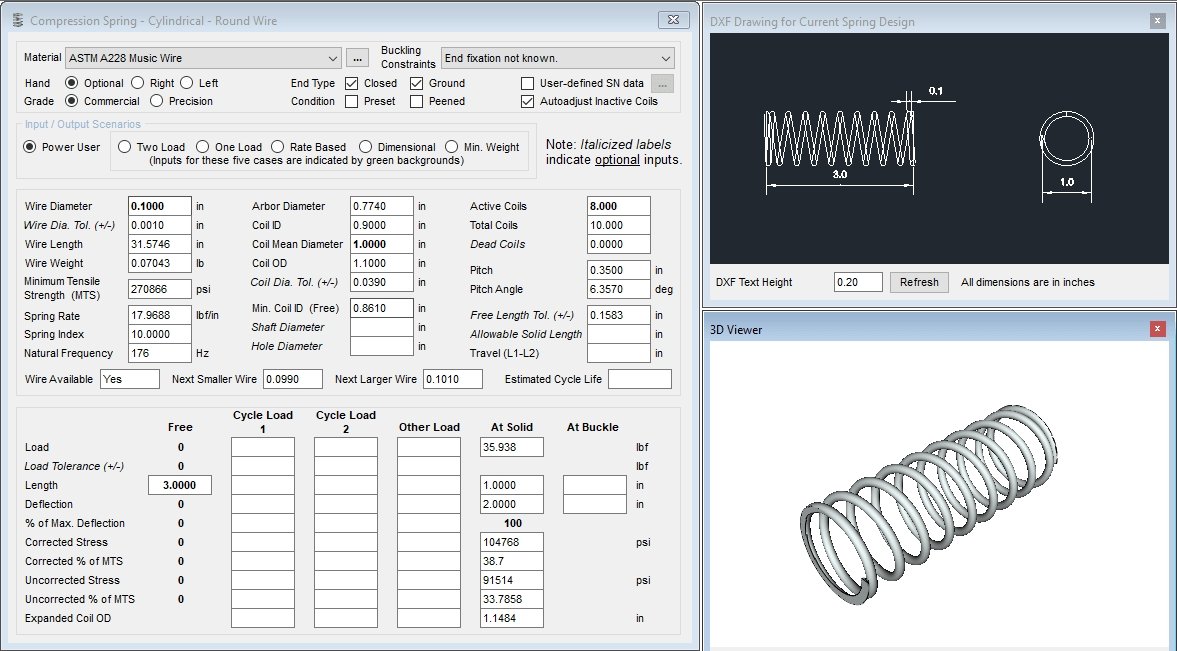

Metering Valve Springs

Metering valve springs are critical components in precision fluid control systems, such as fuel injectors, pneumatic regulators, and precision dosing valves. They work in conjunction with a valve spool or diaphragm, precisely controlling flow rate by counteracting fluid pressure with their exact spring force. Any minor deviation in force can lead to a failure in flow control.

| Spring Type | High-Precision Compression Springs, Conical Springs |

| Technical Parameters | Wire diameter: 0.1mm – 2mm. Spring Rate Tolerance: Extremely tight, can be controlled to within ±3% to ±5%. Squareness & Parallelism: The end coils must be highly perpendicular to the spring axis and parallel to each other to prevent side-loading on the valve spool. Linearity: A highly linear relationship between force and displacement must be maintained throughout the entire working travel. Cleanliness: Free of oil, grease, and burrs to avoid contaminating the fluid and wearing the valve body. |

| Material Characteristics | Stainless Steel (17-7PH/SUS316/304): Combines corrosion resistance, temperature resistance, and stable mechanical properties. Specialty Alloys (Inconel, Hastelloy): Used in extreme environments involving high temperatures, high pressures, or highly corrosive chemical media. |

| Surface Treatment | Ultrasonic Cleaning: Removes all manufacturing residues. Passivation: Enhances the corrosion resistance of stainless steel. Electropolishing: Creates an extremely smooth and clean surface, further improving corrosion resistance and fatigue life. |

| Heat Treatment | Vacuum Heat Treatment: Stress relieving is performed in an oxygen-free environment to ensure the highest consistency of spring properties and surface cleanliness. |

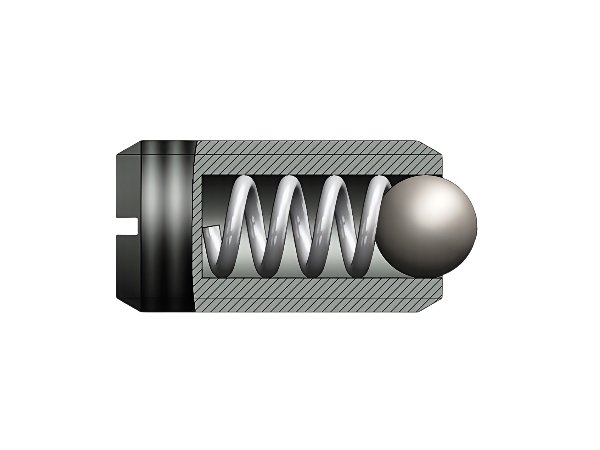

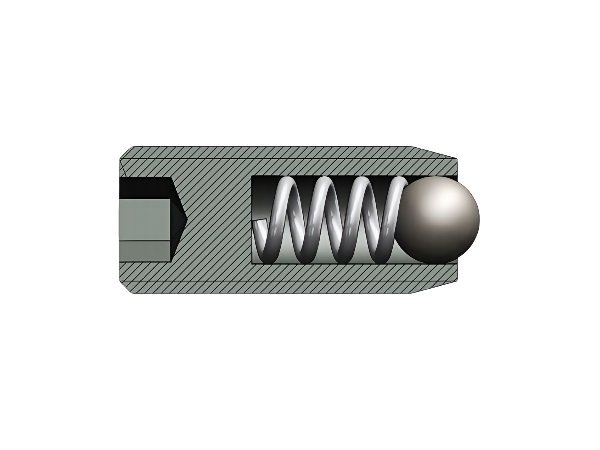

Ball Plunger Springs

A ball plunger is a standard industrial part used for indexing, positioning, and locking, and at its heart is a miniature compression spring. This spring provides a precise preload to the steel ball within the plunger, enabling quick positioning as the ball engages or disengages from a detent or hole. The quality of the spring directly dictates the plunger’s positioning accuracy and service life.

| Spring Type | Micro Compression Springs |

| Technical Parameters | Wire Diameter: Extremely fine, typically between 0.1mm and 0.8mm. Outer Diameter: Miniature in size, requiring a precision fit with the plunger body. Force Consistency: Very low variation in force from spring to spring within a batch, ensuring consistent performance for every plunger. Closed & Ground Ends: Ensures the spring stands stable within the plunger body and transmits pressure evenly. |

| Material Characteristics | Stainless Steel (SUS302/304): The most common material, providing sufficient strength and excellent corrosion resistance for most industrial environments. Carbon Steel: Cost-effective and capable of achieving very high strength through heat treatment. |

| Surface Treatment | Passivation: The standard treatment to enhance the rust-resistance of stainless steel. |

| Heat Treatment | Stress Relieving: Ensures the tiny spring does not take a permanent set under continuous compression. Zinc Plating: Provides excellent rust and wear resistance. |

Flush Handle Springs

A flush handle spring is part of a toilet tank’s flushing mechanism. Its primary function is to automatically return the flush handle to its initial position after it has been pressed or lifted. This type of spring is constantly submerged in water or in a high-humidity environment, so it must possess extremely strong corrosion resistance.

| Spring Type | Torsion Springs, Extension Springs |

| Technical Parameters | Wire diameter: 0.5mm – 3mm. Working Angle / Length: Designed according to the handle’s rotational or lifting mechanism. Torque / Force Output: Must be sufficient to overcome the weight and friction of the handle and linkage assembly. Corrosion Resistance Level: Must withstand long-term exposure to tap water and cleaning agents. Lifespan: Meets the high-frequency use requirements of residential or public facilities. |

| Material Characteristics | Stainless Steel (SUS302/304): Due to its excellent rust-proof properties, it is the only economical and reliable choice for this type of application. Music Wire: High strength and low cost, but requires a reliable surface treatment to prevent rust. |

| Surface Treatment | Generally No Additional Treatment: Corrosion-resistant materials are used directly. Passivation: Enhances the anti-rust capabilities of stainless steel. |

| Heat Treatment | Stress Relieving: Ensures the spring maintains its return force after repeated use. |

Chamber Return Springs

Chamber return spring is a broad category referring to any spring used to return a moving component—such as a piston, slide, or spool—to its home position after actuation in a mechanical, hydraulic, or pneumatic system. They are the power source for enabling automatic cycles and safe resets, commonly found in valves, actuators, clutches, and circuit breakers.

| Spring Type | Compression Springs |

| Technical Parameters | Wire diameter: 0.3mm – 3.0mm. Operating Environment: The effects of temperature, lubricating oils, hydraulic fluids, and other media must be considered. Resistance to Set / Permanent Deformation: Must maintain its free length and force under high stress. Dynamic Performance: In high-frequency reciprocating motion, resonance and fatigue must be considered. |

| Material Characteristics | Alloy Steel (55CrSi/60Si2Mn): Materials specifically designed for high-stress, dynamic-load springs, possessing excellent strength and fatigue life. Stainless Steel (17-7PH/SUS304): Used for chamber return applications that also require corrosion resistance. Specialty Alloys (Inconel): Used for chamber return in high-temperature environments. |

| Surface Treatment | Oiling: Provides basic rust prevention and lubrication. Powder Coating: Offers superior protection against corrosion and abrasion. Zinc / Chrome Plating: Enhances corrosion resistance. |

| Heat Treatment | Quenching & Tempering: To achieve high strength and toughness. Shot Peening: Dramatically improves fatigue life; a standard process for dynamic, high-load springs. |

Our Solution Process

We provide an end-to-end solution to ensure your project progresses efficiently and successfully.

1. Concept & Design Consultation

Discuss your application needs, performance targets, and regulatory requirements with our engineers.

2. Material Selection & Feasibility Analysis

We recommend the most suitable materials and processes based on function, cost, and compatibility.

3. Rapid Prototyping & Sampling

Leveraging our dedicated prototype line, we deliver functional samples in days for your design verification.

4. Testing, Validation & Optimization

We verify spring performance with fatigue, load, and other mechanical testing, iterating the design based on results.

5. Process Validation & Scale-up Production

After successful IQ/OQ/PQ validation, we transfer the project to our certified production lines for stable, repeatable, high-volume manufacturing.

.png)