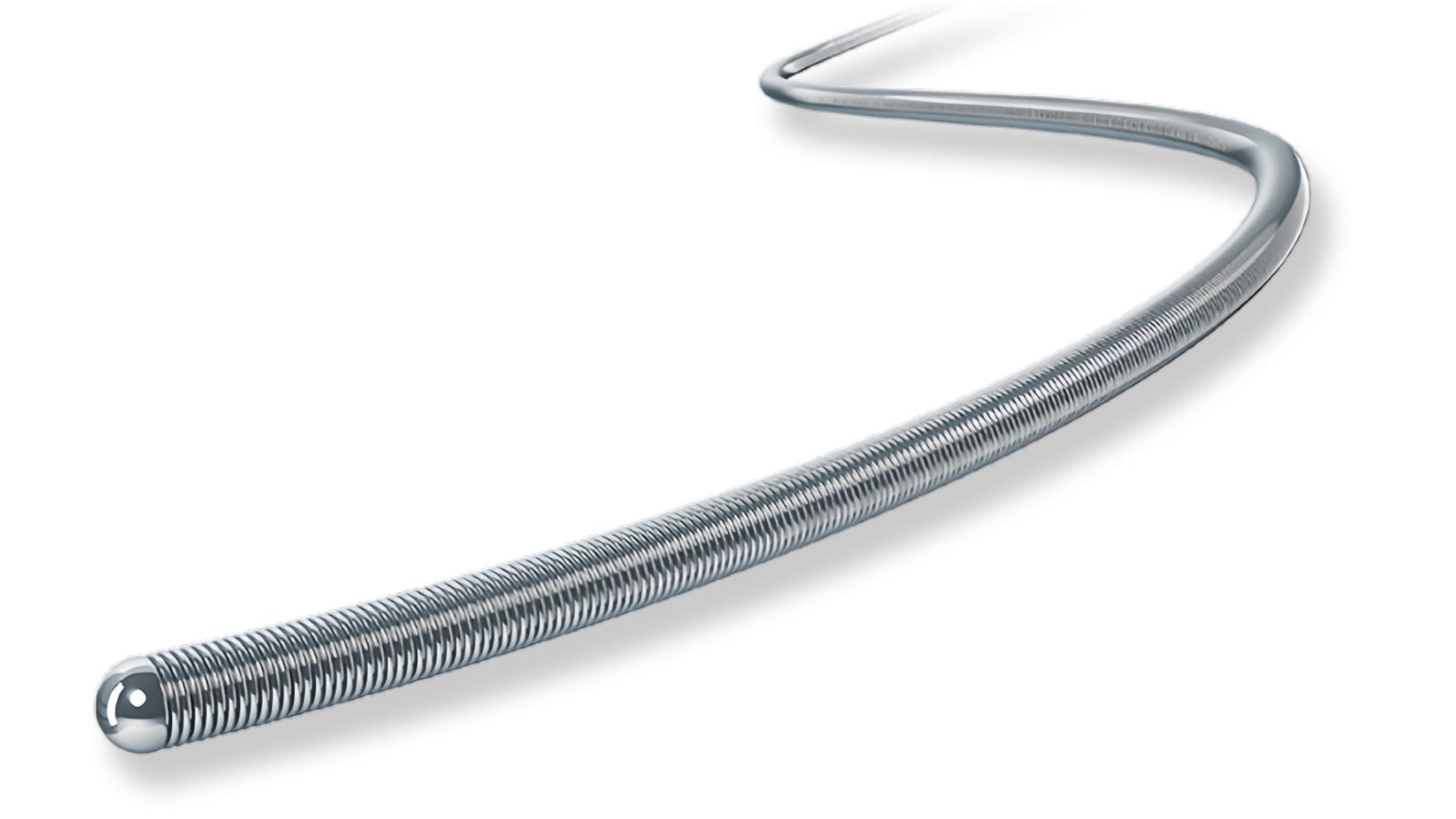

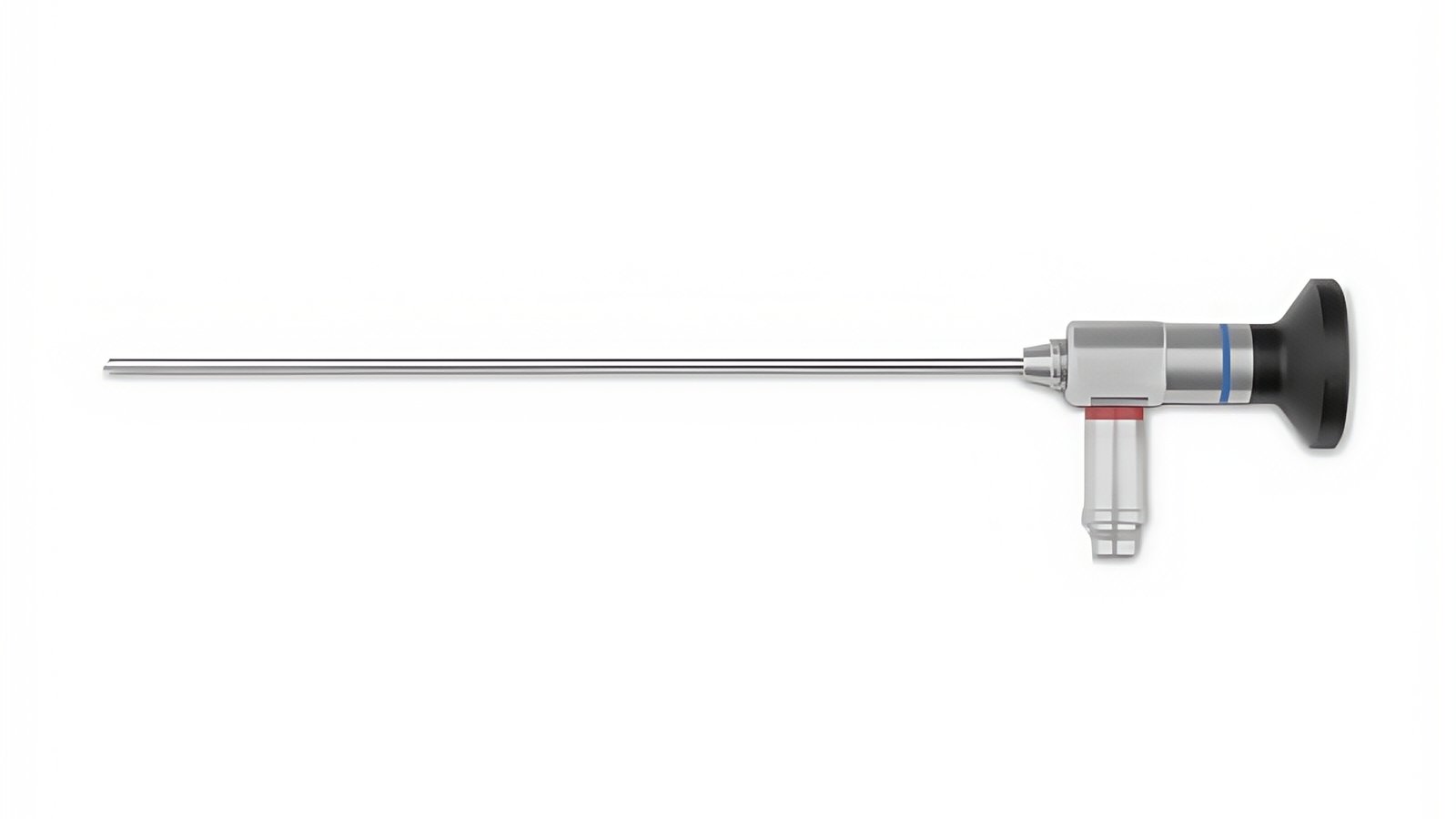

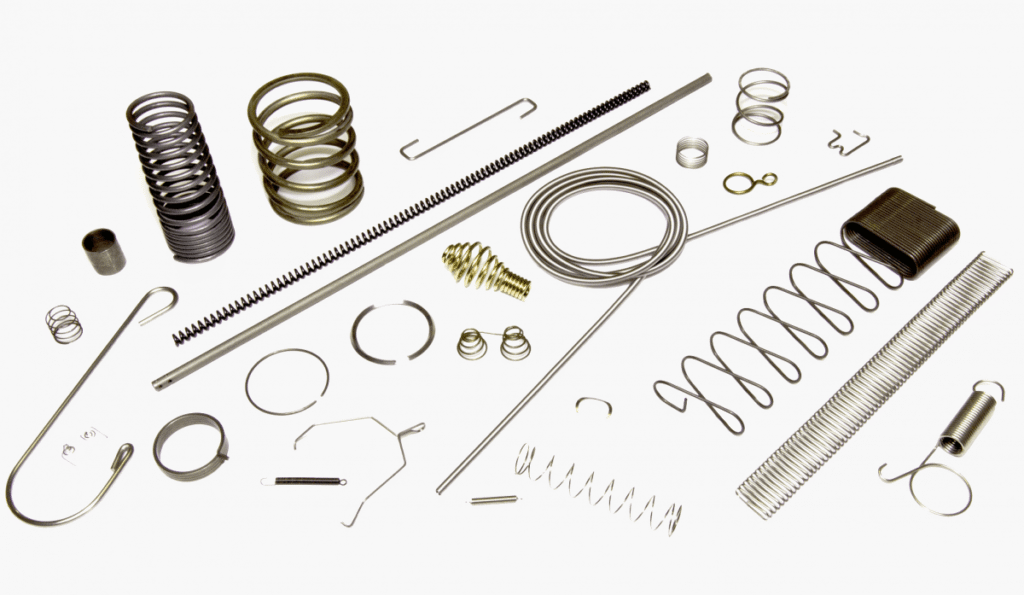

Within modern medical devices, microscopic yet precise springs play a critical role. They are the core components that enable precise control, reliable actuation, and essential functionality. From guidewires and catheters used in minimally invasive surgery to drug delivery systems and life-support equipment, spring technology is indispensable to every critical function.

As a medical springs manufacturer, ZW Precision Hardware understands this responsibility. We are not only a spring manufacturer but also your dedicated engineering partner from concept to full-scale production. With sub-micron precision, superior material science, and a rigorous quality system, we provide the critical support for every breakthrough in life sciences.

Our Core Competencies

In the medical field, where precision, reliability, and safety are absolute, choosing the right component supplier is critical. We have earned the trust of leading medical device companies worldwide through these core advantages.

Our Medical Spring Applications

Our precision springs are indispensable components that enable the critical functionality of numerous cutting-edge medical devices.

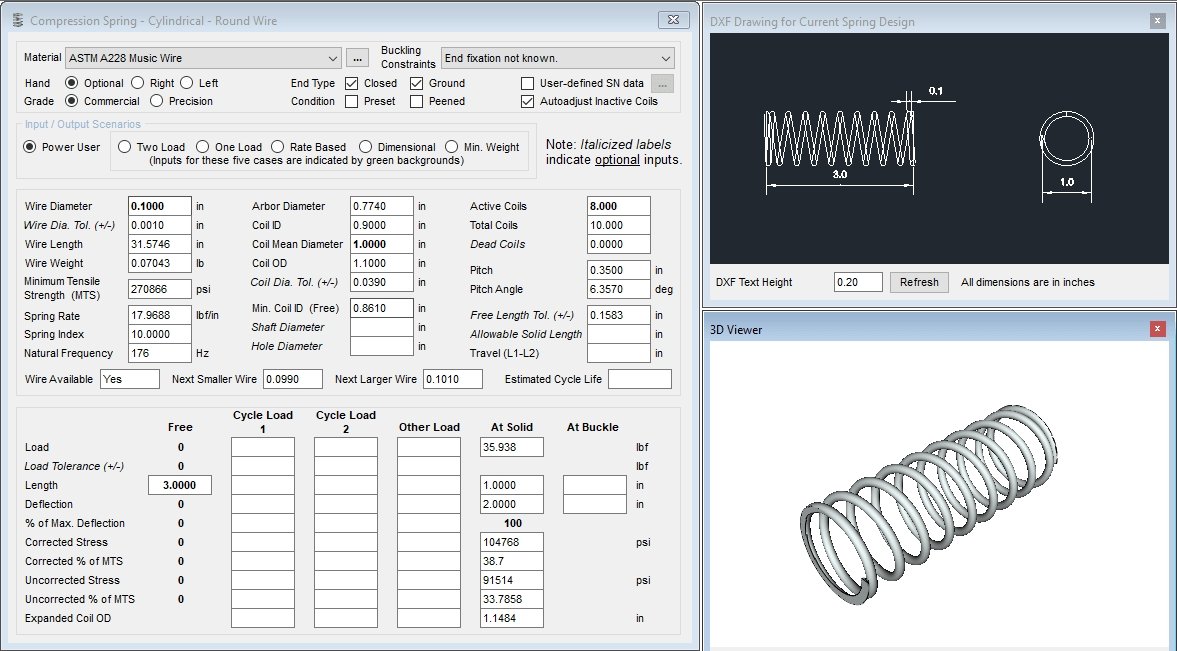

Our Technical Capabilities

We transform your engineering drawings into superior-performance components through our advanced processes and meticulous controls.

Spring Product Technical Specifications

| Application Area | Common Spring Types | Key Technical Parameters | Common Materials | Common Heat Treatments | Common Surface Treatments |

| Guidewires | • Micro Coils • Variable/Multi-Pitch Coils | • Wire Dia. (d): 0.02mm – 0.15mm (0.0008″ – 0.006″) • Outer Dia. (OD): 0.15mm – 1.0mm (0.006″ – 0.039″) • Length Tol.: ±0.1mm (±0.004″) • Surface Finish (Ra): < 0.1μm • Pitch: Variable pitch capable, tol. ±0.01mm • End Treatment: Laser welding, Precision grinding | • Platinum-Iridium (Pt-Ir) • 316LVM Stainless Steel • Tungsten/W-Rhenium (W/W-Re) • Gold (Au) | • Vacuum Stress Relief • Steam Shaping | • Electropolishing • PTFE Coating • Hydrophilic/Hydrophobic Coating |

| Catheters | • Reinforcement Coils • Round/Flat/Square Wire Coils | • Wire Dia. (d): 0.1mm – 0.8mm (or equiv. cross-section) • Outer Dia. (OD): 0.5mm – 10mm (0.020″ – 0.394″) • Length Tol.: ±0.5mm (±0.020″) • Surface Finish (Ra): 0.2μm – 0.4μm • Pitch: Variable, closed or open pitch • End Treatment: Precision cutting, Deburring | • 304V / 316LVM Stainless Steel • Nitinol | • Stress Relief Annealing | • Passivation • Cleaning (Oil-Free) |

| Clips | • Micro Torsion Springs • Micro Compression Springs • Wire Form Clips | • Wire Dia. (d): 0.05mm – 0.5mm (0.002″ – 0.020″) • Outer Dia. (OD): 0.3mm – 3.0mm (0.012″ – 0.118″) • Length Tol.: ±0.05mm (±0.002″) • Load/Torque Tol.: ±5% ~ ±10% • Surface Finish (Ra): < 0.2μm • Pitch: As per design • End Treatment: Custom legs/angles (torsion), Closed & ground (compression) | • 316LVM Stainless Steel • Titanium Alloys • MP35N® | • Age/Precipitation Hardening • Vacuum Heat Treatment | • Electropolishing • Passivation |

| Snares | • Precision Compression Springs (Actuation/Return) • Micro Torsion Springs (Ratchet) | • Wire Dia. (d): 0.1mm – 1.0mm (0.004″ – 0.039″) • Outer Dia. (OD): 1.0mm – 10mm (0.039″ – 0.394″) • Length Tol.: ±0.2mm (±0.008″) • Load Tol.: ±8% ~ ±10% • Surface Finish (Ra): < 0.8μm • Pitch: As per design • End Treatment: Closed & ground | • 304 Stainless Steel • Music Wire | • Stress Relief Annealing | • Nickel Plating • Passivation |

| Forceps | • Micro Compression/Extension Springs • Custom Wire Form Actuators | • Wire Dia. (d): 0.1mm – 0.8mm (0.004″ – 0.031″) • Outer Dia. (OD): 0.5mm – 5.0mm (0.020″ – 0.197″) • Length Tol.: ±0.1mm (±0.004″) • Load Tol.: ±10% • Surface Finish (Ra): < 0.4μm • Pitch: As per design • End Treatment: Custom hooks (extension), Closed & ground (compression) | • 17-7PH / 304 Stainless Steel • MP35N® (for reusable) | • Precipitation Hardening (17-7PH) • Stress Relief Annealing | • Passivation • Laser Marking |

| Pumps & Syringe Systems | • High-Energy Power Springs (Auto-Injectors) • Precision Comp./Torsion (Pens) • Constant-Force Springs (Pumps) | • Wire Dia. (d): 0.5mm – 3.0mm (0.020″ – 0.118″) • Outer Dia. (OD): 3.0mm – 30mm (0.118″ – 1.181″) • Length Tol.: ±0.5mm (±0.020″) • Load Tol.: ±3% ~ ±8% • Surface Finish (Ra): < 0.8μm • Pitch: As per high-load design • End Treatment: Closed & ground, Squaredness guaranteed | • High-Strength Stainless Steel (e.g., 17-7PH, 302) • Elgiloy®, MP35N® (for power springs) | • Quench & Temper• Pre-setting • Precipitation Hardening | • Passivation • Cleanroom Packaging (ISO 8) |

| Endoscopes | • Bending Section Coil Pipes • Brake Coils | • Wire Dia. (d): 0.2mm – 1.5mm (or equiv. cross-section) • Outer Dia. (OD): 1.5mm – 15mm (0.059″ – 0.591″) • Length Tol.: ±0.5mm (±0.020″) • Surface Finish (Ra): ID/OD < 0.1μm • Pitch: Closed or open pitch • End Treatment: Precision cutting, Face polishing | • 304 / 316L Stainless Steel • Titanium Alloys (for lightweighting) | • Stress Relief Annealing • Bright Heat Treatment | • Ultrasonic Cleaning • Electropolishing |

Medical Material Properties

| Material Name | Material Type | Commercial Specification | Density (g/cm³) | Min. Tensile Strength | Modulus of Elasticity (E) | Modulus in Torsion (G) | Operating Temp. Range | Key Properties | Typical Applications |

| 316LVM Stainless Steel | Austenitic Stainless Steel | ASTM F138, ISO 5832-1 | ~8.00 | ~1,240 MPa / 180 ksi (Spring Temper) | ~193 GPa / 28 Msi | ~73.1 GPa / 10.6 Msi | -200°C to 300°C | • Excellent biocompatibility • High purity (vacuum melted) • Excellent corrosion resistance • Good ductility | Surgical instruments, guidewire cores, catheter reinforcement coils, long-term implants, orthopedic plates & screws |

| 17-7PH Stainless Steel | Precipitation-Hardening Stainless Steel | AMS 5528, ASTM A693 | ~7.81 | ~1,585 MPa / 230 ksi (Cond. CH900) | ~204 GPa / 29.6 Msi | ~78 GPa / 11.3 Msi | -50°C to 315°C | • Very high strength and hardness • Good corrosion resistance • Hardenable by heat treatment | Reusable surgical instruments, medical clips, springs, high-strength structural components |

| Nitinol | Shape Memory Alloy | ASTM F2063 | ~6.45 | ~1,300 MPa / 188 ksi (Superelastic) | ~40-80 GPa / 6-12 Msi (Phase Dependent) | ~20-30 GPa / 3-4 Msi | -100°C to 260°C | • Shape memory effect • Superelasticity (~8% strain recovery) • Excellent biocompatibility | Vascular stents (self-expanding), orthodontic archwires, superelastic guidewires, retrieval baskets, cardiac occluders |

| MP35N® Alloy | Cobalt-Based Superalloy | ASTM F562 | ~8.43 | ~1,790 MPa / 260 ksi (Spring Temper) | ~231 GPa / 33.5 Msi | ~82.7 GPa / 12 Msi | -200°C to 315°C | • Ultra-high strength, toughness & ductility • Excellent fatigue & creep resistance • Superb corrosion resistance, non-magnetic | Pacemaker lead wires, high-stress springs, vascular clips, orthopedic implants, long-term implantable devices |

| Titanium Alloy (Ti-6Al-4V ELI) | Alpha-Beta Titanium Alloy | ASTM F136, ISO 5832-3 | ~4.43 | ~860 MPa / 125 ksi (Annealed) | ~114 GPa / 16.5 Msi | ~44 GPa / 6.4 Msi | -200°C to 400°C | • Very high strength-to-weight ratio • Excellent biocompatibility • MRI/CT compatible • Excellent fatigue & fracture toughness | Artificial joints (hip/knee), bone plate systems, spinal implants, pacemaker cases, dental implants |

| Platinum-Iridium (Pt-20%Ir) | Precious Metal Alloy | Similar to ASTM F560 | ~21.6 | ~550 MPa / 80 ksi (Annealed) | ~218 GPa / 31.6 Msi | ~85 GPa / 12.3 Msi | -200°C to 800°C | • Very high density & radiopacity • Excellent biocompatibility • Superb corrosion resistance | Radiopaque markers for guidewire tips, electrode tips, cardiac catheter electrode rings, markers in radiotherapy |

| Tungsten | Refractory Metal | ASTM F288 | ~19.3 | ~1,500 MPa / 218 ksi (Drawn) | ~411 GPa / 59.6 Msi | ~161 GPa / 23.3 Msi | >1000°C | • Extremely high density & radiopacity • Extremely high hardness & stiffness | Micro-coils for radiopaque guidewire tips, radiation shielding components, ablation electrodes |

Our Solution Process

We provide an end-to-end solution to ensure your project progresses efficiently and successfully.

1. Concept & Design Consultation

Discuss your application needs, performance targets, and regulatory requirements with our engineers.

2. Material Selection & Feasibility Analysis

We recommend the most suitable materials and processes based on function, cost, and compatibility.

3. Rapid Prototyping & Sampling

Leveraging our dedicated prototype line, we deliver functional samples in days for your design verification.

4. Testing, Validation & Optimization

We verify spring performance with fatigue, load, and other mechanical testing, iterating the design based on results.

5. Process Validation & Scale-up Production

After successful IQ/OQ/PQ validation, we transfer the project to our certified production lines for stable, repeatable, high-volume manufacturing.

.png)