In our daily lives, springs are the invisible force behind countless products, from the toaster we use each morning and the stapler on our desk, to the exercise equipment at the gym. They are the unsung heroes that provide functionality, convenience, and a quality user experience to consumer products. Our line of Consumer Product Springs is dedicated to providing global manufacturers with high-quality, cost-effective solutions that make your products more reliable, durable, and favored by consumers.

ZW Precision Hardware understands that consumer products have strict requirements for cost, high-volume consistency, and long-term operational safety. Through optimized designs, efficient automated production lines, and rigorous quality control, we ensure that every batch of springs meets our clients’ precise specifications. Whether it’s providing a crisp tactile feel for a button or supporting a critical safety function, our springs are the dependable choice you can trust.

Our Core Competencies

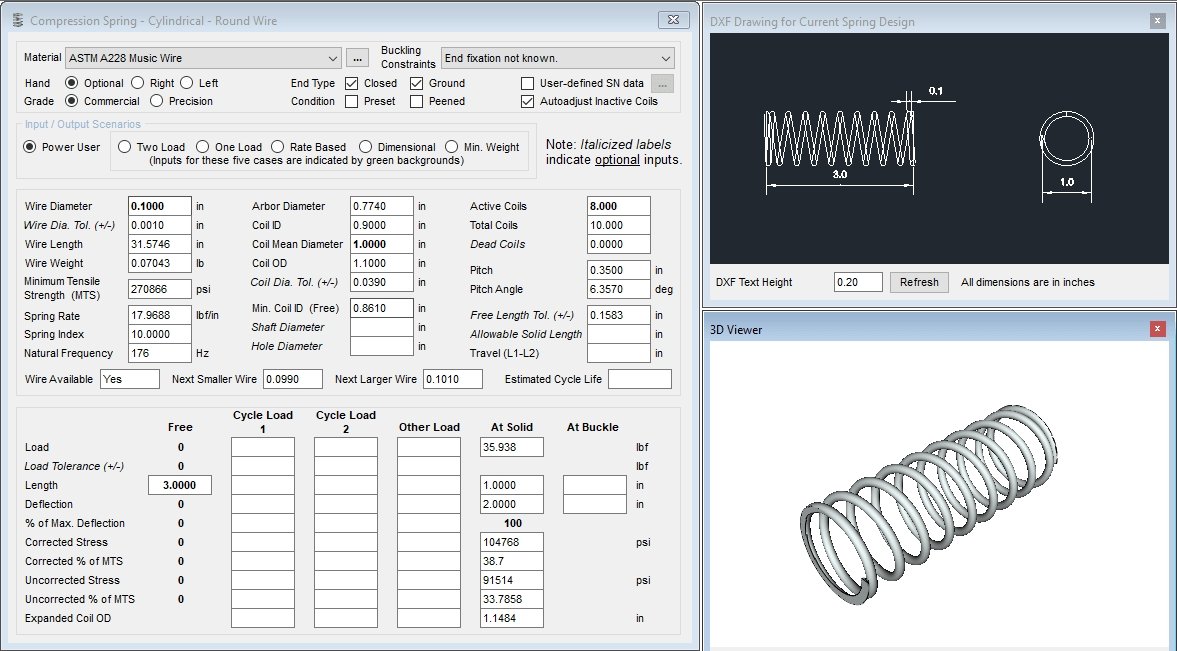

Our Typical Products Specifications

Home Appliances Springs

Home appliance springs are core components that ensure the proper function and safety of electrical appliances. From the suspension systems in washing machines and the closing mechanisms of refrigerator doors to the counter-balance hinges on oven doors, these springs must operate reliably for years in complex environments involving moisture, high temperatures, or heavy loads. They directly impact the user experience and the overall lifespan of the product.

| Spring Type | Heavy-Duty Compression/Extension Springs (for suspension), Torsion Springs (for door hinges/lids), Constant Force/Power Springs (for cord retractors), Precision Compression Springs (for buttons/valves) |

| Technical Parameters | Wire diameter/Material Thickness: 0.1mm – 4.0mm. Load Capacity: Precisely calculated based on the application, from a few Newtons to several thousand. Operating Environment: Must be resistant to high temperatures (ovens) and moisture/corrosion (washing machines, dishwashers). High Fatigue Life: Meets requirements for tens of thousands of door-opening, button-pressing, or shock-absorption cycles. Dimensional Control: Requires a precision fit within the appliance’s assembly space. |

| Material Characteristics | High Carbon Steel/Music Wire: Highly cost-effective and the base material for most appliance springs. Stainless Steel: Used in wet or high-corrosion environments, such as inside dishwashers or coffee makers. Alloy Steel: Used in applications requiring extreme strength and resistance to high-temperature creep, such as oven door hinges. |

| Surface Treatment | Zinc Plating: The most common anti-corrosion treatment; cost-effective and suitable for wet and dry environments. Electrophoretic Coating (E-coating): Provides a uniform and superior anti-corrosion layer that is both aesthetic and durable, ideal for washing machine suspension springs. Passivation: For stainless steel materials, enhances their natural corrosion resistance. |

| Heat Treatment | Quenching & Tempering: For high-carbon and alloy steels to achieve high strength and toughness. Stress Relieving: Eliminates forming stresses to guarantee the stability of spring dimensions and forces. Shot Peening: Used for springs requiring high fatigue life, such as in washing machine suspension, to significantly improve durability. |

Office Supplies Springs

While the springs in office supplies may be small, they are essential to their function. The return action of a stapler, the retraction of a ballpoint pen, or the clamping force of a binder clip all rely on these tiny precision springs. Such applications demand extreme consistency, a long cycle life, and a highly competitive cost to accommodate large-scale automated production.

| Spring Type | Torsion Springs (for staplers/clips), Compression Springs (for pens/hole punches), Wire Forms (for paper clips) |

| Technical Parameters | Wire Diameter: 0.1mm – 2.0mm. High-Volume Consistency: Automated production ensures force and dimensions are highly consistent across millions of units. Cycle Life: Meets requirements for thousands to tens of thousands of repetitive uses (e.g., clicking, clamping). Cost Control: Achieves an extremely low per-unit cost through optimized design and efficient production. |

| Material Characteristics | Music Wire: High strength makes it a preferred material for many office supply springs; requires plating for corrosion protection. Stainless Steel: Good corrosion resistance without plating and a clean appearance, suitable for higher-end office products. High Carbon Steel: The lowest cost option, suitable for internal parts with low corrosion-resistance requirements. |

| Surface Treatment | Nickel Plating: Provides a bright, aesthetic finish and good rust prevention. Zinc Plating: An economical choice for rust prevention. Natural / Passivated: For stainless steel materials, cleaning and passivation are often sufficient. |

| Heat Treatment | Stress Relieving: A standard process to stabilize spring properties. |

Sports & Fitness Equipment Springs

Springs in sports and fitness equipment are directly related to the user’s experience and personal safety. From providing resistance in chest expanders and hand grippers, to cushioning the weight stacks in large multi-gyms and supporting trampolines, these springs must withstand enormous impacts and high-frequency reciprocating motions. Their strength, toughness, and fatigue resistance are central to their design.

| Spring Type | Heavy-Duty Extension Springs (for trampolines), Heavy-Duty Compression Springs (for weight stacks/shock absorption), Large Wire Diameter Torsion Springs (for resistance arms) |

| Technical Parameters | Wire diameter: 0.2mm – 15mm. Maximum Safe Load: Must have a sufficient safety factor to prevent failure under overload. Fatigue Life: Designed to withstand hundreds of thousands or even millions of extension or compression cycles. Spring Rate: Determines the “weight” or “resistance” of the workout and must be precisely controlled. Impact Absorption: Requires good toughness to absorb the shock generated during exercise. |

| Material Characteristics | Alloy Steel: Specifically designed for high-stress, high-fatigue applications; the premier material for load-bearing fitness springs. High Carbon Steel: Suitable for lighter-load fitness accessories or equipment. Stainless Steel: Used for water sports equipment or high-end machines requiring extreme corrosion resistance. |

| Surface Treatment | Zinc / Chrome Plating: Provides excellent resistance to corrosion from sweat and rust, with an attractive metallic finish. Powder Coating: Offers a thick, durable, and colorful protective layer; a common choice for large fitness equipment. E-coating: Superior corrosion resistance with a uniform coating. |

| Heat Treatment | Quenching & Tempering: Imparts high strength and a high elastic limit to the spring. Shot Peening: A mandatory process for all high-strength, dynamic-load fitness springs to significantly improve their fatigue resistance. |

Tools & Accessories Springs

From garden pruning shears and workshop vises to the internals of power tools, springs are key to making tools work efficiently. They provide return action, clamping force, or trigger force, enabling single-handed operation and improving work efficiency. Tool springs must be robust and durable, capable of resisting oil, dust, and the wear and tear of repeated use.

| Spring Type | Torsion Springs (for pliers/shears), Constant Force/Power Springs (for tape measures), Compression Springs (for locking mechanisms), Extension Springs (for return mechanisms) |

| Technical Parameters | Wire diameter/Material Thickness: 0.2mm – 4.0mm. Durability: Must be able to withstand impact, vibration, and improper use. Environmental Resistance: Able to resist oils, chemicals, and temperature fluctuations. Force Stability: Provides a reliable return or clamping force even after long-term use. Cycle Life: Meets the high-intensity, high-frequency use requirements of professional-grade tools. |

| Material Characteristics | High Carbon Steel/Music Wire: The top choice for most hand tool springs due to its high strength and cost-effectiveness. Stainless Steel: Used for gardening shears, food processing tools, or medical instruments that require easy cleaning and rust prevention. Alloy Steel: Used for industrial-grade tools that are subjected to extreme impact or load. |

| Surface Treatment | Black Oxide / Phosphate: Provides good corrosion resistance and oil absorption, making it ideal for workshop environments. Zinc / Nickel Plating: Offers stronger rust prevention and a cleaner appearance. Passivation: Suitable for stainless steel tool springs. |

| Heat Treatment | Stress Relieving: Stabilizes spring properties and prevents deformation. Quenching & Tempering: Increases the strength and wear resistance of carbon and alloy steels. |

Our Solution Process

We provide an end-to-end solution to ensure your project progresses efficiently and successfully.

1. Concept & Design Consultation

Discuss your application needs, performance targets, and regulatory requirements with our engineers.

2. Material Selection & Feasibility Analysis

We recommend the most suitable materials and processes based on function, cost, and compatibility.

3. Rapid Prototyping & Sampling

Leveraging our dedicated prototype line, we deliver functional samples in days for your design verification.

4. Testing, Validation & Optimization

We verify spring performance with fatigue, load, and other mechanical testing, iterating the design based on results.

5. Process Validation & Scale-up Production

After successful IQ/OQ/PQ validation, we transfer the project to our certified production lines for stable, repeatable, high-volume manufacturing.

.png)