In the high-tech realms of telecommunications and precision electronics, every single component is critical. Our line of Communication Electronics Springs is engineered to meet the stringent demands of this industry for high precision, unwavering reliability, and superior performance. From smartphones and networking equipment to critical medical electronic devices, our springs play a core role in ensuring signal integrity, power stability, and the long-term operational reliability of your products.

ZW Precision Hardware employs state-of-the-art manufacturing processes and the highest quality conductive and high-strength materials. Every spring we produce undergoes meticulous design calculations and rigorous testing. Whether it’s an antenna spring for signal transmission, an EMI shielding spring to prevent electromagnetic interference, or a battery spring to ensure continuous power, we are dedicated to providing optimized solutions that support the superior performance and market competitiveness of your products.

Our Core Competencies

Our Typical Products Specifications

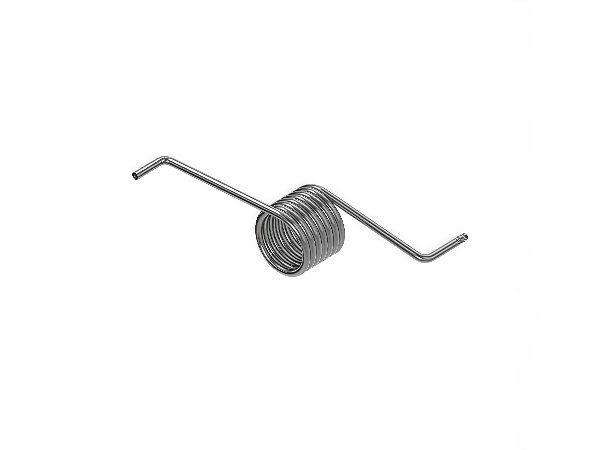

Antenna springs

Antenna springs are indispensable components in mobile and communication devices, designed to ensure a stable electrical connection between the antenna module and the main circuit board. They typically function as contact or compression springs, requiring an ideal balance of reliable contact force, outstanding electrical conductivity, and corrosion resistance to guarantee clear and stable signal transmission.

| Spring Type | Precision Compression Springs, Conical Springs, Contact Springs, Custom Wire Forms |

| Technical Parameters | Wire Diameter: 0.1mm – 1.5mm Outer/Inner Diameter: Customized to fit the client’s antenna module structure Free Length: 2.0mm – 20.0mm Force/Pressure: Precisely controlled at specific working points, with tolerances as tight as ±10% Contact Resistance: < 20 mΩ |

| Material Characteristics | Beryllium Copper (BeCu): The premier choice for high-performance applications, offering an exceptional combination of conductivity, high strength, and excellent fatigue and corrosion resistance. Phosphor Bronze: Provides a good balance of conductivity and elasticity, offering a cost-effective solution. Stainless Steel (SUS304/316): Offers excellent corrosion resistance and strength, typically requiring plating to enhance conductivity. |

| Surface Treatment | Gold Plating: Provides the best conductivity and superior resistance to corrosion and oxidation. Silver Plating: Offers excellent conductivity at a lower cost than gold. Tin Plating: Ensures good conductivity and solderability. |

| Heat Treatment | Stress Relieving: Eliminates internal stresses from the forming process to stabilize spring dimensions and mechanical properties. Age Hardening (for BeCu, etc.): Significantly increases the material’s strength and elasticity after forming. |

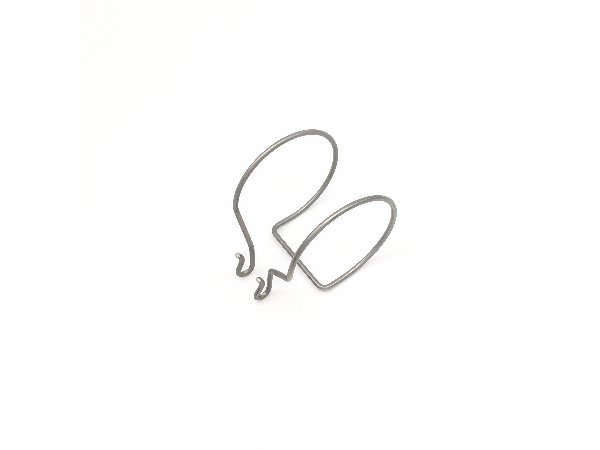

EMI Shielding Springs

Electromagnetic Interference (EMI) shielding springs, also known as grounding springs or RFI shielding springs, are used to close gaps in the enclosures of electronic devices or between components. They prevent the leakage or intrusion of electromagnetic waves by establishing a reliable, low-impedance path between two conductive surfaces, which is crucial for passing EMC (Electromagnetic Compatibility) certification.

| Spring Type | Leaf Springs / Fingerstock: Provides multi-point contact, suitable for panels, doors, and other planar connections. Canted Coil Springs: Deliver near-constant force axially or radially, ideal for shielding round or irregularly shaped gaps. Custom Stampings: Shielding solutions designed for specific cavity structures. |

| Technical Parameters | Material Thickness/Wire Diameter: 0.05mm – 0.5mm Compressed/Working Height: Precisely designed based on gap size and required force. Grounding Resistance: Extremely low, typically in the milliohm (mΩ) range. Shielding Effectiveness: Achieves a specific decibel (dB) value within a designated frequency range (e.g., 10MHz – 10GHz). |

| Material Characteristics | Beryllium Copper (BeCu): The optimal choice, combining high conductivity, high elasticity, and outstanding mechanical strength with excellent fatigue resistance. Stainless Steel (SUS301): For applications requiring high elasticity where shielding is a secondary concern. Phosphor Bronze: A good all-around performer, offering a balance between cost and performance. |

| Surface Treatment | Tin Plating: Enhances conductivity and corrosion resistance, and provides a good base for soldering. Nickel Plating: Offers excellent wear and corrosion protection. No Plating Required (for BeCu): The inherent high conductivity of the copper alloy is sufficient for many shielding applications. Conductive Adhesive Tape: Can be used as a supplementary mounting method in certain applications. |

| Heat Treatment | Stress Relieving: Ensures the spring maintains its shape and elastic force after long-term compression. Age Hardening (for BeCu): Optimizes the spring’s mechanical properties, ensuring a reliable contact force over its lifespan. |

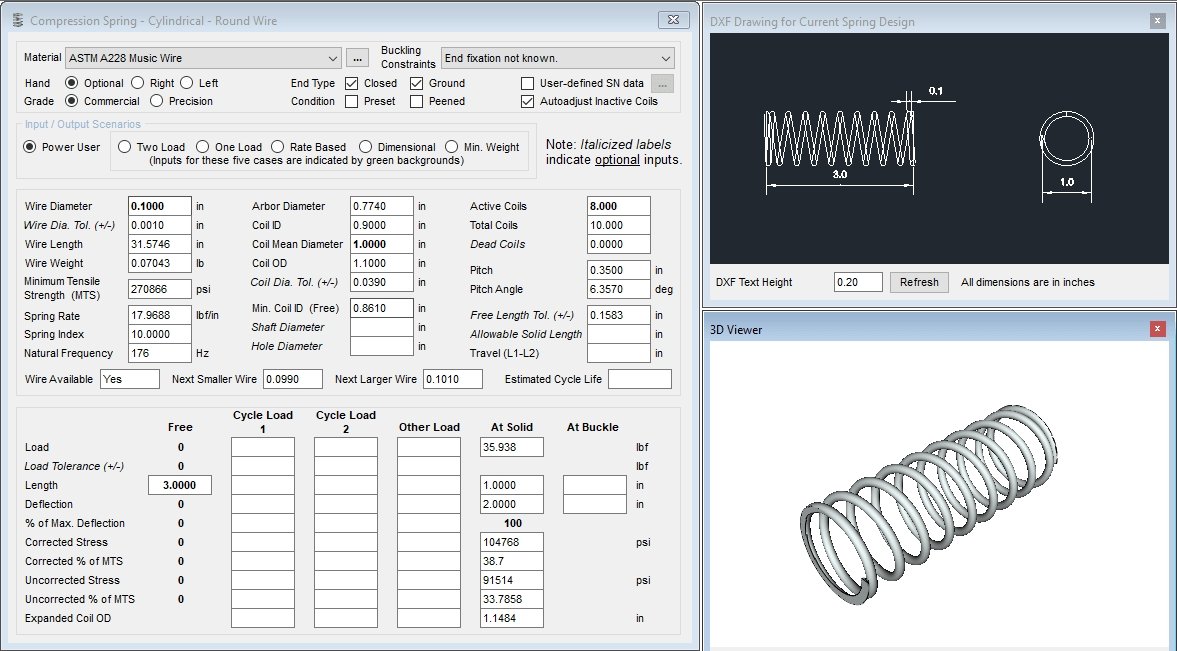

Module Connector Springs

Module connector springs are core components within board-to-board connectors, sockets, and various pluggable modules. They exist as micro-springs inside pogo pins or as stamped metal contacts, providing a separable yet reliable connection for signals and power. These springs demand extremely high precision, a very long cycle life, and the ability to provide stable force within a minimal space.

| Spring Type | Micro Compression Springs: Commonly used inside pogo pins. Contact Clips / Stampings: Used in SIM card trays, SD card sockets, FPC connectors, etc. Torsion Springs: Employed in the locking or ejection mechanisms of connectors. |

| Technical Parameters | Wire Diameter/Material Thickness: As low as 0.03mm. Dimensional Tolerance: High precision, can be controlled to ±0.02mm. Cycle Life: Designed to meet requirements from thousands to millions of mating cycles. Current Rating: Designed based on application needs, from milliamps (mA) to several amps (A). Contact Force: Maintained stably within a specified travel to ensure low contact resistance. |

| Material Characteristics | Music Wire: High strength and low cost, but requires plating for corrosion protection and conductivity. Often used inside probe pins. Stainless Steel (SUS304/316): Excellent corrosion resistance and mechanical properties, a common material for pogo pin springs. Beryllium Copper (BeCu): Used for contact stampings that need to carry higher currents or require superior conductivity. |

| Surface Treatment | Gold Plating: The standard finish, providing the lowest contact resistance and the best durability and corrosion resistance. Selective Gold Plating: Gold is applied only to critical contact areas to reduce cost. Palladium-Nickel (PdNi) with Gold Flash: Offers higher wear resistance for high-mating-cycle applications. |

| Heat Treatment | Precision Stress Relieving: Performed in a controlled atmosphere to prevent surface oxidation and ensure dimensional stability. Vacuum Heat Treatment: Used for high-performance materials to prevent any surface contamination and maximize mechanical properties. |

Battery Springs

Battery springs or battery contacts are one of the most common spring types found in all portable electronic devices. Their primary functions are twofold: first, to securely hold the battery in place within the battery compartment using elastic force; and second, to establish a low-resistance conductive path between the battery terminal and the device’s circuitry.

| Spring Type | Conical or Cylindrical Compression Springs: The most common type, accommodates tolerance variations in battery length, ypically used for the negative terminal. Leaf Springs / Stampings: Often used for positive terminal contact or in space-constrained designs, such as coin cell holders. |

| Technical Parameters | Wire Diameter/Material Thickness: 0.2mm – 2.0mm Supported Battery Types: AA, AAA, C, D, 9V, 18650, Coin Cells, etc. Mounting Style: Surface Mount (SMT), Through-Hole, Snap-in Contact Resistance: Kept as low as possible to minimize power loss. |

| Material Characteristics | Carbon Steel / Music Wire: Lowest cost and good strength, but must be plated to prevent rust and ensure conductivity. Stainless Steel (SUS304/301): Naturally corrosion-resistant without plating, but has average conductivity. Ideal for applications where cost and corrosion resistance are priorities. Phosphor Bronze: Good conductivity and elasticity, with better corrosion resistance than carbon steel. Beryllium Copper (BeCu): The highest-performance option. Its conductivity is close to that of pure copper, combined with high strength and fatigue resistance, making it ideal for high-performance or high-reliability devices. |

| Surface Treatment | Nickel Plating: The most common finish. It provides good corrosion and wear resistance at a high cost-effectiveness. It also matches the nickel casing of batteries, preventing galvanic corrosion. Silver Plating: Higher conductivity than nickel, but at a higher cost. It is prone to tarnishing (which does not affect conductivity). Tin Plating: Provides good solderability and conductivity. |

| Heat Treatment | Stress Relieving: Ensures the spring does not take a permanent set under the constant pressure of the battery, maintaining a consistent contact force. |

Electrical Contact Springs

Electrical contact springs are critical conductive components used in switches, relays, circuit breakers, and various power connectors. Their design objective is to establish, maintain, or interrupt a current-carrying circuit between two conductors. These springs must possess both excellent mechanical properties (to provide and maintain contact pressure) and superior electrical properties (to minimize resistance and temperature rise).

| Spring Type | Precision Stampings: Such as contact blades in sockets or switch contact arms. Wire Forms: Used for contact clips and brush springs in high-current applications. Coil Springs: Provide the opening and closing force for contacts in relays and circuit breakers. |

| Technical Parameters | Wire Diameter: 0.1mm – 2.5mm Current/Voltage Rating: A core parameter that determines the material and cross-sectional area. Contact Pressure: Designed to break through any surface oxide films and establish a stable, low-resistance connection. Temperature Rise: Must remain within safe limits when carrying the rated current. Mechanical Life: Switches and relays may require cycle lives ranging from tens of thousands to millions of operations. |

| Material Characteristics | Beryllium Copper (BeCu): The perfect combination of high conductivity and high strength, making it the premier material for high-performance electrical contacts. Phosphor Bronze: Offers excellent elasticity and moderate conductivity, widely used in low-to-medium current applications. Brass: Good conductivity but weaker elasticity, suitable for static connections or components with low spring-back requirements. High Carbon Steel: High strength but poor conductivity, typically used for mechanical support components of a spring assembly rather than the direct current-carrying part. |

| Surface Treatment | Silver Plating: The standard choice for high-current applications due to its excellent conductivity. Gold Plating: Used for low-level signal or high-reliability applications to prevent fretting corrosion. Tin Plating: An economical choice for general-purpose electrical connections. Composite Plating: Such as silver or gold over a nickel underplate, combining the hardness of the base layer with the conductivity of the top layer. |

| Heat Treatment | Age Hardening / Precipitation Hardening: Used for high-performance alloys like Beryllium Copper to achieve maximum strength and hardness after forming. Stress Relieving: Eliminates processing stress to stabilize the spring’s geometry and mechanical properties. |

Switch Springs

Switch springs are the core mechanical components in all types of switches, including tactile switches, micro switches, keyboard switches, and slide switches. They determine the switch’s operational feel (tactility, linearity), actuation force, return speed, and operational life. Every parameter must be precisely controlled to ensure a consistent and reliable user experience.

| Spring Type | Micro Compression Springs: Used in mechanical keyboard switches and detector switches. Metal Domes: Used in membrane switches and tactile switches to provide a crisp “click” and haptic feedback. Torsion Springs: Used in rotary or toggle switches. Leaf Springs: Used in micro switches to achieve a snap-action (rapid make/break) motion. |

| Technical Parameters | Wire Diameter/Material Thickness: 0.05mm – 2mm Actuation Force: The force required to press the switch, measured in gram-force (gf) or Newtons (N). Actuation Travel: The distance from the resting position to the point of actuation. Total Travel: The maximum distance the switch can be depressed. Force-Travel Curve: A graph describing the relationship between force and travel, which defines whether a switch feels linear, tactile, or clicky. Lifespan: Ranges from tens of thousands to over 100 million cycles. |

| Material Characteristics | Stainless Steel (SUS301/304): The most common material, providing excellent fatigue life and corrosion resistance, key to a switch’s long-term reliability. Music Wire: High strength and low cost, suitable for internal applications where corrosion resistance is less of a concern. Phosphor Bronze / Beryllium Copper: Used when the switch spring must also carry an electrical current, providing conductivity. |

| Surface Treatment | Passivation: A process for stainless steel that enhances its natural corrosion resistance. Nickel/Gold Plating: Used when the spring itself also functions as an electrical contact to reduce contact resistance. Oiling: Light oiling to ensure smooth movement and prevent corrosion. |

| Heat Treatment | Stress Relieving: Critically important for stabilizing the spring force, ensuring it remains consistent after millions of operations. Austempering: A treatment for high-carbon steel that provides excellent toughness and fatigue life. |

Our Solution Process

We provide an end-to-end solution to ensure your project progresses efficiently and successfully.

1. Concept & Design Consultation

Discuss your application needs, performance targets, and regulatory requirements with our engineers.

2. Material Selection & Feasibility Analysis

We recommend the most suitable materials and processes based on function, cost, and compatibility.

3. Rapid Prototyping & Sampling

Leveraging our dedicated prototype line, we deliver functional samples in days for your design verification.

4. Testing, Validation & Optimization

We verify spring performance with fatigue, load, and other mechanical testing, iterating the design based on results.

5. Process Validation & Scale-up Production

After successful IQ/OQ/PQ validation, we transfer the project to our certified production lines for stable, repeatable, high-volume manufacturing.

.png)