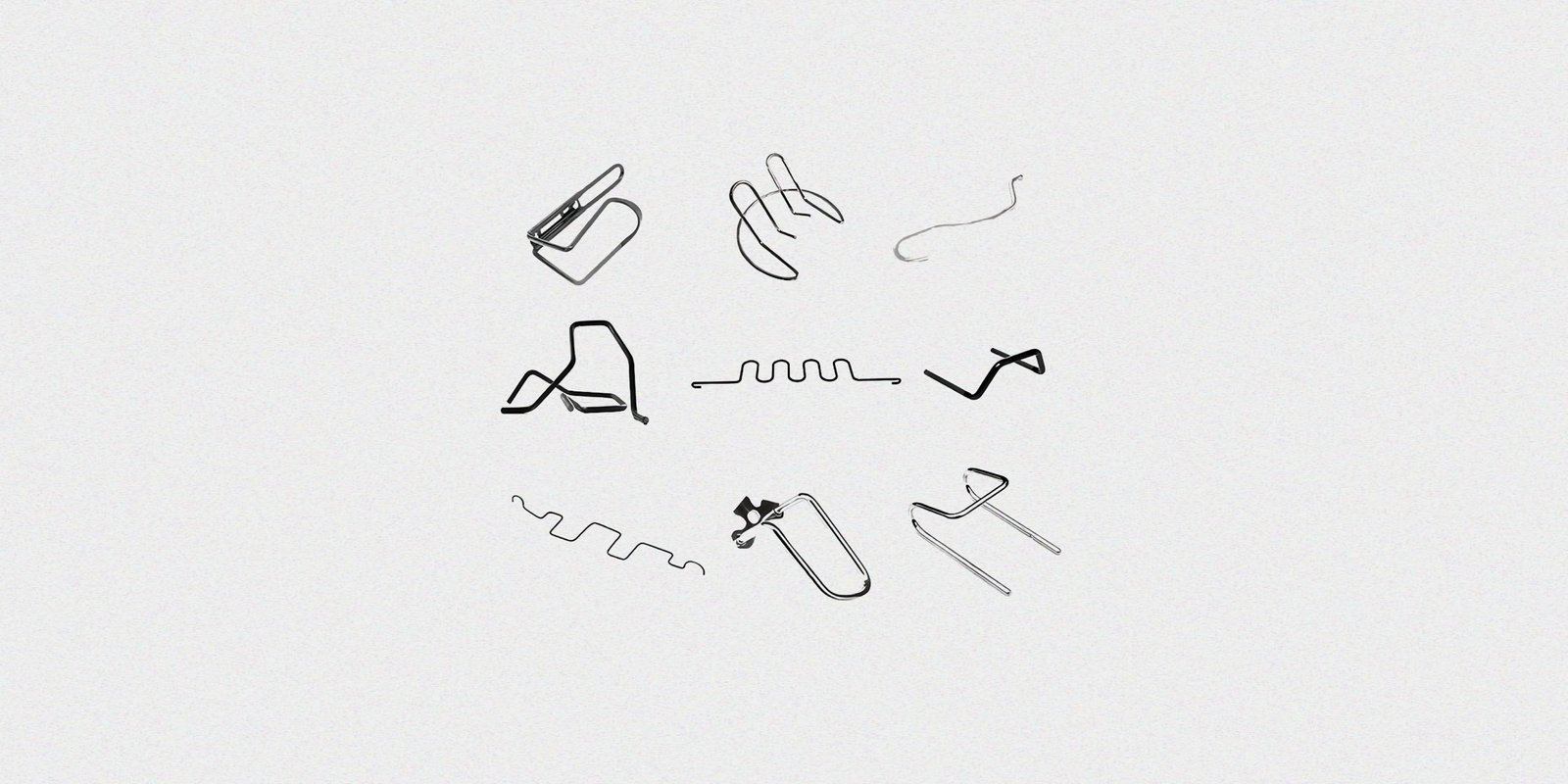

When a standard compression, extension, or torsion spring cannot meet your unique design requirements, a custom wire form is the ideal solution. Simply put, wire forming is the process of shaping wire through a series of precise bending, coiling, and cutting operations to create a specific 2D or 3D component. These components perform functions far more complex than simple energy storage and release.

They are the “transformers” of modern industrial design, serving as the skeletons, linkages, clips, supports, or hooks within mechanical systems. From adjustment levers in automotive seating and guide frames in medical devices to antennas in electronic equipment, wire forms are everywhere. Their lightweight, high-strength, and highly customizable nature provides limitless space for product innovation.

ZW Precision Hardware is your engineering realization partners with state-of-the-art multi-axis CNC technology and deep material science expertise. We can form metal wire into any complex 2D or 3D shape you require, solving your unique mechanical challenges.

Our Manufacturing Capabilities

We invest in the most advanced technology and the best talent to ensure we can transform the most complex designs into the highest quality products.

Advanced CNC Forming Technology

Our multi-axis CNC wire forming machines can complete all processes—including feeding, bending, coiling, chamfering, and cutting—in a single, automated sequence. This not only guarantees extremely high dimensional accuracy and repeatability but also eliminates the need for expensive secondary tooling. This significantly reduces your development costs and lead times, making it ideal for custom prototypes and small-batch production.

Unlimited Design Possibilities

From simple S-hooks and R-clips to incredibly complex 3D spatial linkages, our technical capabilities are virtually limitless. If you can design it, we can most likely make it. Our engineering team embraces challenges and is eager to work with you to solve the most difficult design problems.

One-Stop Solution

Beyond our core wire forming services, we offer a comprehensive range of secondary operations and value-added services, including:

- End-Types: Threading, knurling, chamfering, grinding, head forming.

- Precision Machining: Stamping, swaging, drilling.

- Joining Processes: Spot welding, laser welding.

- Assembly Services: Assembling wire forms with other plastic or metal components.

Support from Prototype to Production

We understand the entire product development lifecycle. We can provide you with fast, low-cost functional prototypes for design validation and also possess the large-scale automated production capacity to ensure a stable, reliable, and cost-effective supply as you scale to mass production.

Our Product Functions & Applications

Linkages & Levers

As critical components for transmitting motion and force, they often replace heavier and more complex machined or cast parts, such as:

- Automotive seat adjustment mechanism

- Engine control rods

- Paper handling linkages in printers

- Control arms in industrial machinery

Clips & Fasteners

They provide reliable fixing, clamping, or positioning functions through their unique elasticity and shape, such as:

- Cable management clips in electronic enclosures

- Tube and hose retainers in automobiles

- Industrial equipment safety R-clips

- Mounting clips for lighting fixtures

Guides & Supports

They act as structural components, providing support, protection, or path guidance for other parts, such as:

- Guide frames for catheters in medical devices

- Yarn guides in textile machinery

- Pre-embedded supports in construction

- Support rods for shelving

Hooks & Hangers

Leveraging the material’s strength to provide reliable connection points for suspension, lifting, and tensioning applications, such as:

- Material hooks for industrial assembly lines

- S-hooks for outdoor gear

- Hooks for retail displays

- Support rings for filter bags

Our Technical Specifications

| Wire Diameter Range | 0.1mm – 12.0mm |

| Common Materials | Carbon Steels: Music Wire, High & Low Carbon Steel (e.g., 1008/1018) Stainless Steels: 302, 304, 316 and 17-7PH Alloy Steels: Chrome Silicon and Chrome Vanadium Non-ferrous Metals: Beryllium Copper, Phosphor Bronze, Brass and Aluminum High-Temp Alloys: Inconel® and Monel® |

| Forming Capabilities | Complex 2D & 3D spatial forming Multi-axis CNC control (up to 12 axes) Tight tolerance control on concentricity, co-planarity and angles |

| End Type Capabilities | Special hooks, loops and rings Threading (internal/external) Chamfering, grinding and cutoff Spherical, conical and other custom end shapes |

| Surface Treatments | Plating: Zinc (various colors), Nickel, Chrome and Tin Coating: Powder Coating, E-coating and PVC Dip Coating Other: Passivation, Black Oxide, Phosphating and Polishing |

Our Collaborative Process

1. Consultation & Drawing Analysis

You provide a drawing, sample, or design concept, and our engineers conduct a preliminary analysis.

2. DFM & Quotation

We provide Design for Manufacturability (DFM) feedback to optimize cost and performance, along with a detailed quotation.

3. Prototyping & Validation

We quickly produce samples for your testing and validation.

4. Precision Production & QC

Upon approval, we move to high-precision, large-scale production with rigorous quality control.

5. Delivery & Post-Sales Support

We offer global delivery and continuous technical support.

.png)