Precision springs are essential components in many industries. Their role in medical applications is particularly crucial. From surgical instruments to diagnostic equipment, these springs ensure functionality, reliability, and accuracy. In this article, we’ll explore the types of precision springs used in medical environments, how they’re manufactured, and why precision is so important.

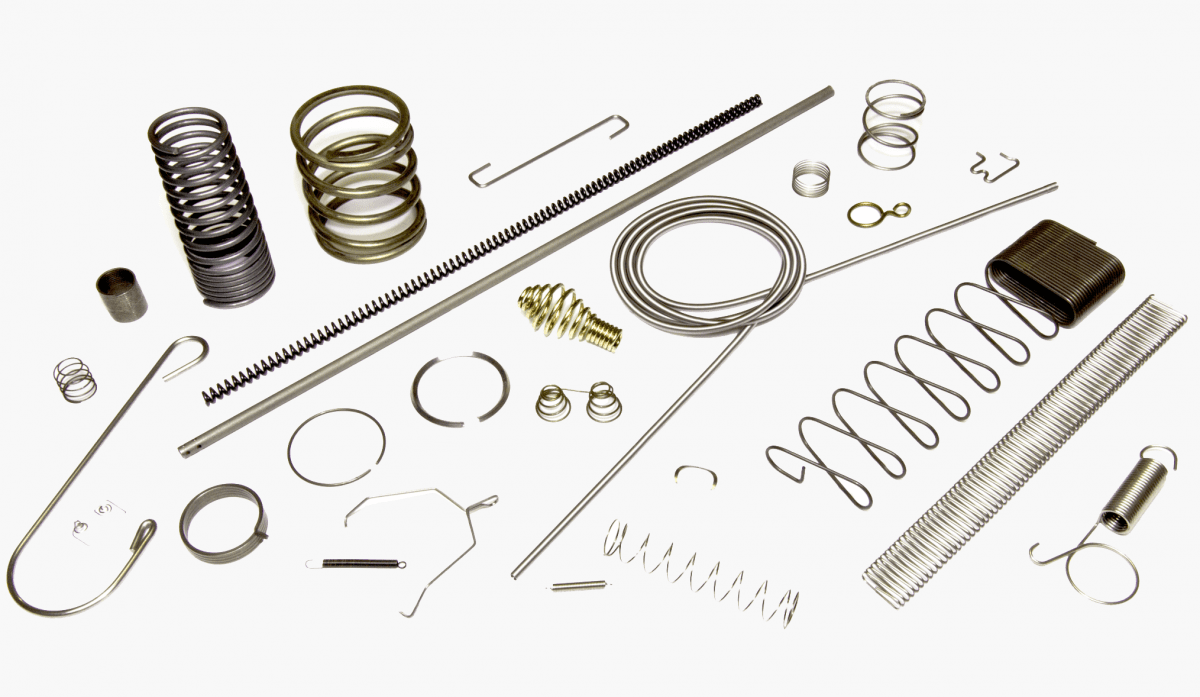

Medical devices often require components that can perform with high accuracy and reliability. Precision springs, such as precision extension springs, precise torsion springs, and precision coil springs, are designed to meet these exacting standards. Their ability to maintain consistent performance under varying conditions makes them essential in medical technology.

Types of Precision Springs Used in Medicine

Precision Extension Springs

Precision extension springs are used to store energy and provide resistance to pulling forces. In medical applications, they are often found in devices that require controlled movement or tension, such as infusion pumps and surgical staplers.

Precision Torsion Springs

Torsion springs exert a rotational force and are commonly used in applications that require precise angular movement. Medical devices like imaging equipment and patient monitoring systems often rely on these springs to function correctly.

Precision Coil Springs

Coil springs, also known as helical springs, are used for their ability to absorb impact and provide cushioning. In the medical field, they are typically used in shock-absorbing roles, such as in prosthetics or orthopedic devices.

Manufacturing Precision Springs for Medical Use

The manufacturing process of precision springs for medical applications demands exceptional attention to detail and quality control. Here’s how manufacturers ensure these springs meet the necessary standards:

Material Selection

Selecting the right material is critical to the performance of precision medical springs. Common materials include stainless steel, titanium, and specialty alloys, which provide the necessary strength, flexibility, and corrosion resistance required in medical environments.

Precision Engineering

Precision springs are designed to exact specifications to ensure they function as intended in medical devices. Advanced engineering techniques and computer-aided design (CAD) are often used to achieve the necessary accuracy.

Quality Assurance

Quality assurance is a critical aspect of precision springs manufacturing. Rigorous testing is conducted to ensure that each spring meets the required performance standards. This includes stress testing, fatigue testing, and dimensional inspections.

The Importance of Precision in Medical Applications

The precision of these springs is vital for several reasons. Here’s why precision springs are so important in medical applications:

Ensuring Patient Safety

In medical devices, even the smallest component can have a significant impact on patient safety. Precision springs ensure that devices function correctly, reducing the risk of malfunction during critical procedures.

Enhancing Device Performance

Precision springs contribute to the overall performance of medical devices. They provide the necessary force and movement control, allowing devices to operate smoothly and efficiently.

Reliability and Longevity

The reliability of medical devices is paramount, and precision medical springs play a vital role in ensuring this. Their strong build and careful design allow them to be used many times without breaking, which helps the device last longer.

Real-World Examples of Precision Springs in Medical Applications

Precision springs are found in a variety of medical devices. Here are a few examples:

Surgical Instruments

Instruments such as forceps and clamps rely on springs to provide the necessary tension and control during surgical procedures.

Diagnostic Equipment

Diagnostic devices, such as MRI machines and X-ray equipment, use springs to ensure accurate positioning and movement of components.

Drug Delivery Systems

Springs are used in drug delivery systems like insulin pumps and auto-injectors, where they help control the release of medication.

Conclusion

Precision springs are integral to the functionality and reliability of medical devices. Their importance cannot be overstated, as they play a crucial role in ensuring patient safety and enhancing the performance of medical technology. By understanding their role and the manufacturing process behind them, we can better appreciate the critical work that goes into developing these essential components.

In the ever-evolving world of medical technology, precision springs remain an essential component of innovation, pushing the boundaries of possibility and ensuring medical devices continue to operate at their best. Whether it’s a life-saving surgical instrument or a routine diagnostic tool, the precision and reliability of these springs make modern medicine possible.

.png)