At ZW Precision Hardware, we specialize in cutting-edge metal 3D printing technology, delivering innovative additive manufacturing solutions tailored to our customers’ unique requirements. By leveraging advanced metal 3D printing, we efficiently produce complex-shaped metal components with exceptional precision and speed.

Capabilities and Manufacturing Processes

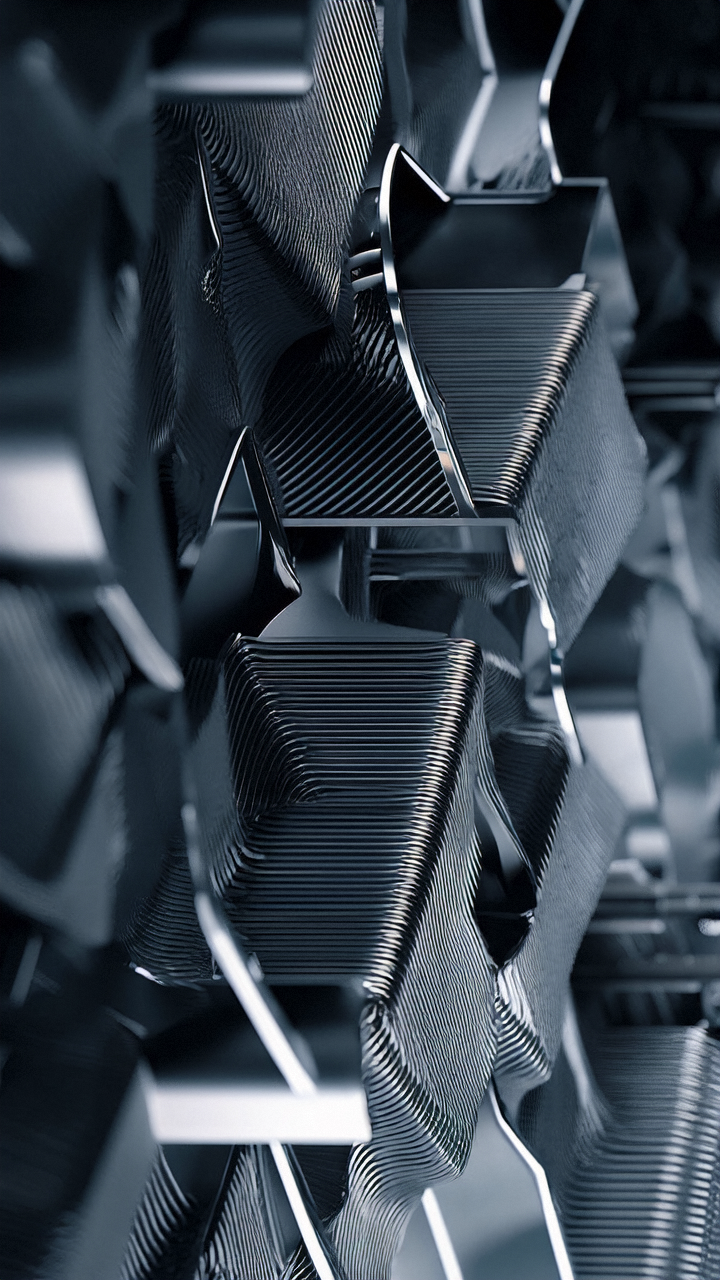

Our metal 3D printing capabilities enable customers to achieve intricate geometric designs that are often impractical with traditional manufacturing methods. This technology facilitates rapid prototype development, low-volume production and fully customized manufacturing, significantly reducing lead times and enhancing design flexibility. We utilize advanced additive manufacturing processes, including Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), to produce high-performance metal components. Our expertise extends to processing a wide range of advanced materials, such as stainless steel, titanium alloys, aluminum alloys and nickel-based alloys. These technologies ensure that our metal parts exhibit superior mechanical properties, intricate structural complexity and exceptional durability.

Industry Applications

Our metal 3D printing solutions serve diverse industries, including automotive, medical and energy sectors, where high-performance metal components are critical. By replacing traditional subtractive manufacturing, metal 3D printing eliminates tool wear, enables direct printing from CAD design files, reduces material waste and allows for lightweight designs without compromising strength and durability.

By integrating advanced metal 3D printing into their production processes, our customers can achieve groundbreaking designs, accelerate product development cycles, optimize manufacturing efficiency and strengthen their competitive advantage in the marketplace. Whether you require small-batch customization, complex prototype manufacturing or functional component production, ZW Precision Hardware’s metal 3D printing services provide reliable, high-quality solutions to meet your needs.

.png)