How does a cold CAD drawing get transformed, step by step, into the high-precision metal component in your hands? This article takes you on a “client’s-eye view” journey through our factory, demystifying the entire process from inquiry to delivery and revealing the rigor and artistry behind precision manufacturing.

A Journey of Precision

Behind every successful hardware product lies a stable and efficient supply chain. As a critical link in this chain, how do we precisely translate your requirements into reality? This journey is about technology and process, but even more so, it’s about communication and trust.

Stop 1: Customer Inquiry & Engineering Evaluation – From “I want” to “I know how”

- Initial Contact: The journey begins with your inquiry. You send us your drawings and technical requirements. Our professional sales engineers—who are more like technical consultants with business acumen—respond promptly to establish contact.

- Deep Dive Analysis: Our engineering team then convenes to review your drawing, much like a team of doctors consulting on a case. This goes beyond looking at dimensions and tolerances; it’s a deep dive to understand the application conditions: What is the final use of this part? What kinds of forces will it endure? What is the operating environment?

- The DFM Report: Based on this analysis, we provide you with a detailed Design for Manufacturability (DFM) report. This might include suggestions like: “We recommend adding a radius to this sharp corner to reduce stress concentration,” “If we change the material from 304 stainless to 17-7PH, we can increase the fatigue life by 5x at the same size,” or “This tolerance can be relaxed, which can save you 15% on the cost.” The goal of this stage is to co-create a solution that is both high-performance and cost-effective.

Stop 2: Tooling Design & Prototyping – From Blueprint to Tangible Part

- The Art of Tooling: For stamped parts, our in-house toolmakers begin designing complex multi-station progressive dies. For wire forms, our CNC programmers write sophisticated motion paths. This is the core step where 2D drawings are elevated to 3D reality.

- Rapid Prototyping: We don’t go straight to mass production. We use our dedicated prototype line to quickly create the first functional samples. These are sent to you for real-world assembly tests, functional validation, and performance evaluation.

- Iteration and Confirmation: If any issues are found during testing, we work with you to quickly adjust the design or process and create new samples. We repeat this until the prototype perfectly meets all your requirements. Your final, written approval is the only “pass” to the next stage.

Stop 3: Mass Production & Process Control – Forging Consistency in a Million Pieces

- SOPs and Automation: Once the prototype is approved, we create a Standard Operating Procedure (SOP) for your product. An operator on a fully automated CNC machine calls up the program, installs the tooling and material, and production officially begins.

- The Power of SPC: We don’t just “set it and forget it.” We take regular samples during production, monitor dimensions with vision systems, and plot SPC (Statistical Process Control) charts. Any minor deviation that trends toward a control limit triggers an immediate alert and adjustment, ensuring the entire production run remains stable and in control.

Stop 4: Secondary Operations & Quality Inspection – From “Workpiece” to “Work of Art”

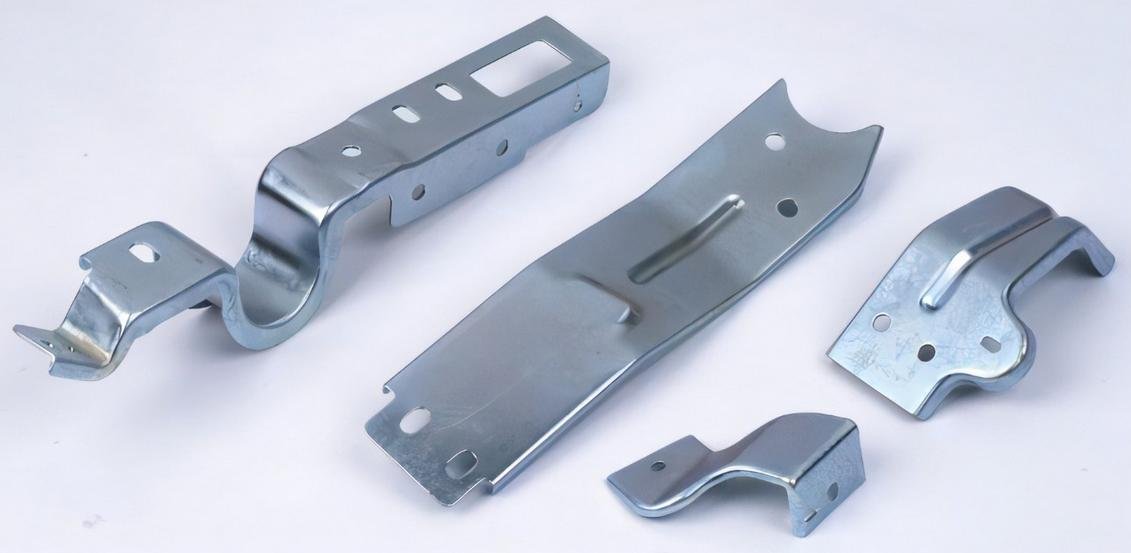

- Refinement: Parts fresh off the machine are still “semi-finished.” They are sent to our secondary operations department for deburring, heat treatment (to achieve the ideal hardness and elasticity), and surface treatment (like plating or passivation to give them their protective and aesthetic “armor”).

- The Final Exam: In our independent quality control center, your products face their most rigorous inspection. Our QC engineers use CMMs, spectrometers, fatigue testers, and other precision instruments to conduct a full “physical exam” of critical dimensions, material composition, mechanical properties, and appearance. Only 100% conforming parts receive a certificate of approval and are cleared for the next step.

Stop 5: Packaging & Global Delivery – Arriving Safely and On Time

- Custom Packaging: We design the most suitable packaging solution based on your product’s characteristics and your requirements, ensuring it is perfectly protected during its long journey.

- Reliable Logistics: We partner with top-tier global logistics companies to ensure your goods are delivered safely and on time to any of your facilities around the world. Our service concludes only with your satisfied receipt of the shipment.

Conclusion

This is more than a production journey; it is a journey of trust. Through a rigorous and transparent process, we turn every uncertainty into a certainty, allowing you to entrust your designs to us with complete confidence.

.png)