ZW Precision Hardware provides innovative Custom Design & Development solutions uniquely tailored to meet specific customer requirements from initial concept through final product realization. Leveraging advanced engineering technologies, precision manufacturing capabilities and an expert R&D team, we deliver accurate and highly efficient customized products suitable for diverse industrial applications.

Design and Engineering Process

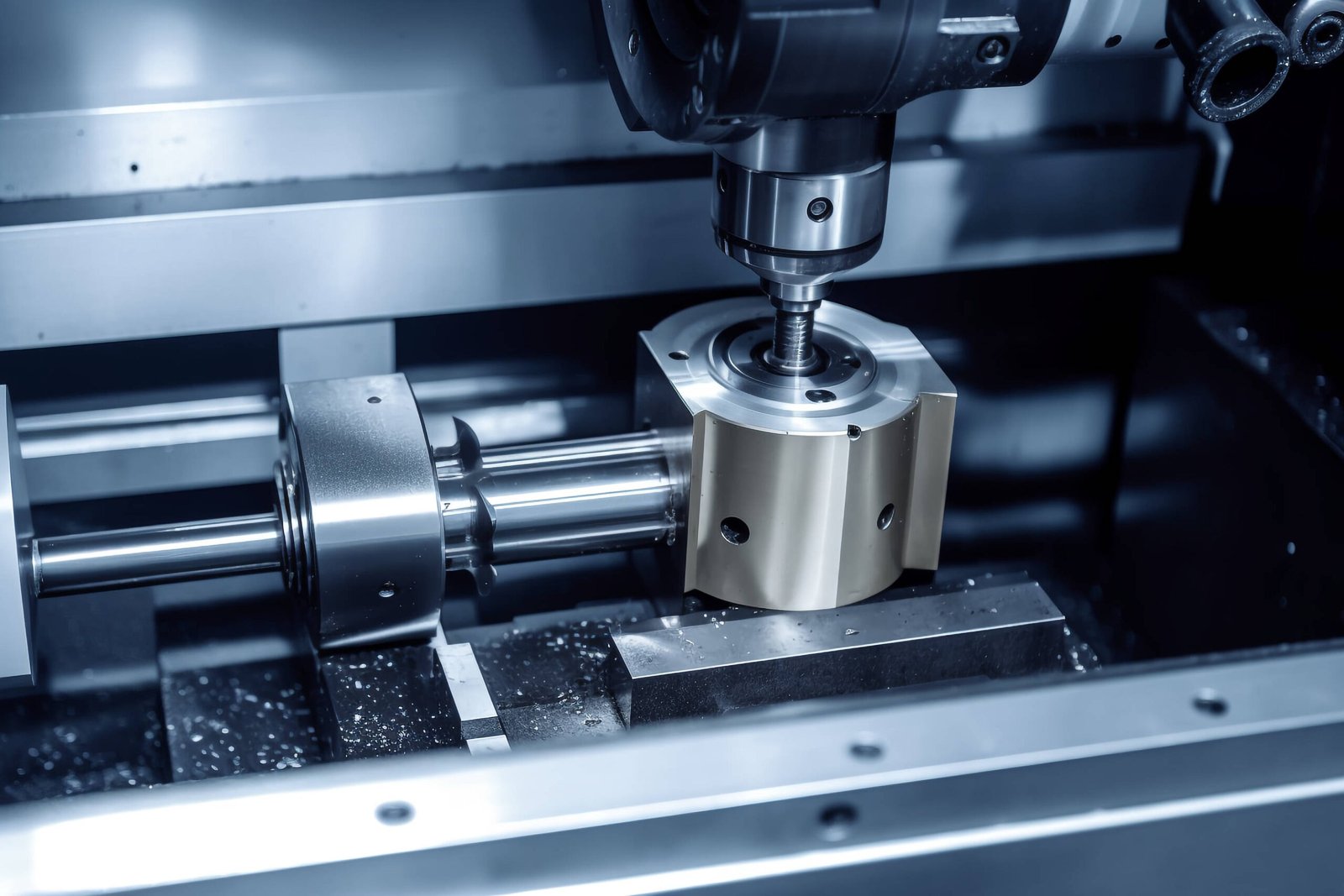

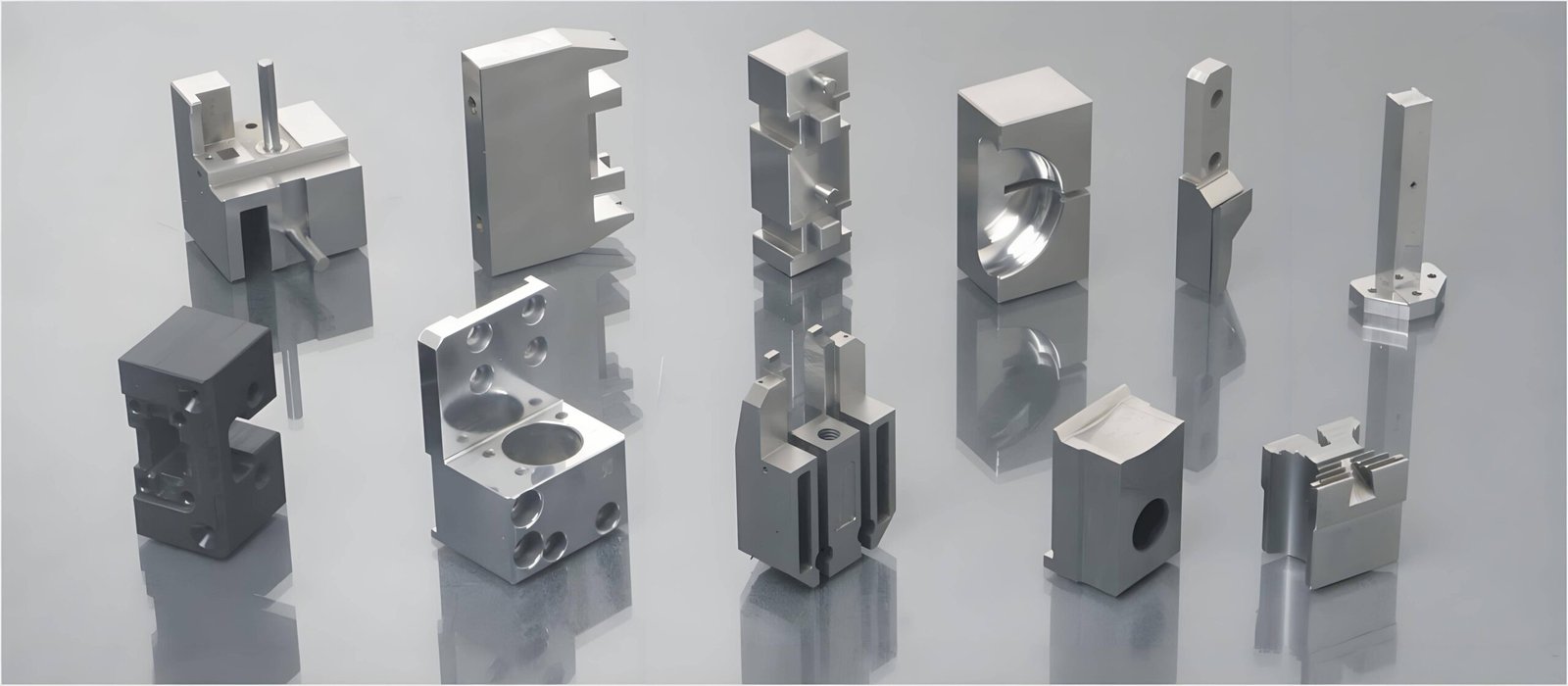

Our comprehensive process begins with detailed requirement analysis, functional optimization and material selection, utilizing advanced CAD/CAE software to achieve precise design modeling, ensuring optimal product performance, exact dimensions and exceptional quality. Cutting-edge manufacturing methods, including CNC machining, stamping, bending and specialized surface treatments, seamlessly transform sophisticated designs into high-quality finished components.

Specialized Component Solutions

ZW Precision Hardware excels in creating custom designs ideal for complex spring assemblies, intricate mechanical components and specialized parts with unique performance demands, such as high-temperature resistance, corrosion protection or compatibility with extreme operational environments.

Industry Applications and Quality

Whether your project involves small-batch prototyping or high-volume industrial production, ZW Precision Hardware effectively supports industries including automotive, medical, electronics, energy and construction. Through ongoing innovation and continuous optimization of our processes, we consistently enhance product quality, enabling our customers to achieve greater market competitiveness and cost-efficiency.

.png)