At ZW Precision Hardware, we offer a range of advanced manufacturing services using cutting-edge technologies like CNC machining, multi-axis machining and micro-stamping process to produce high-precision components for various industries.

CNC Machining

We provide high-precision CNC machining solutions that include milling, turning, drilling and grinding. With advanced CNC technology and a variety of machines including five-axis and CNC lathes, we can handle complex parts for industries like automotive and medical devices. Our efficient processes, precise CAD/CAM programming and strict quality control ensure that we deliver high-quality, reliable components for both small and large production runs. In addition, we offer value-added services like material selection and post-processing to meet our customers’ specific needs.

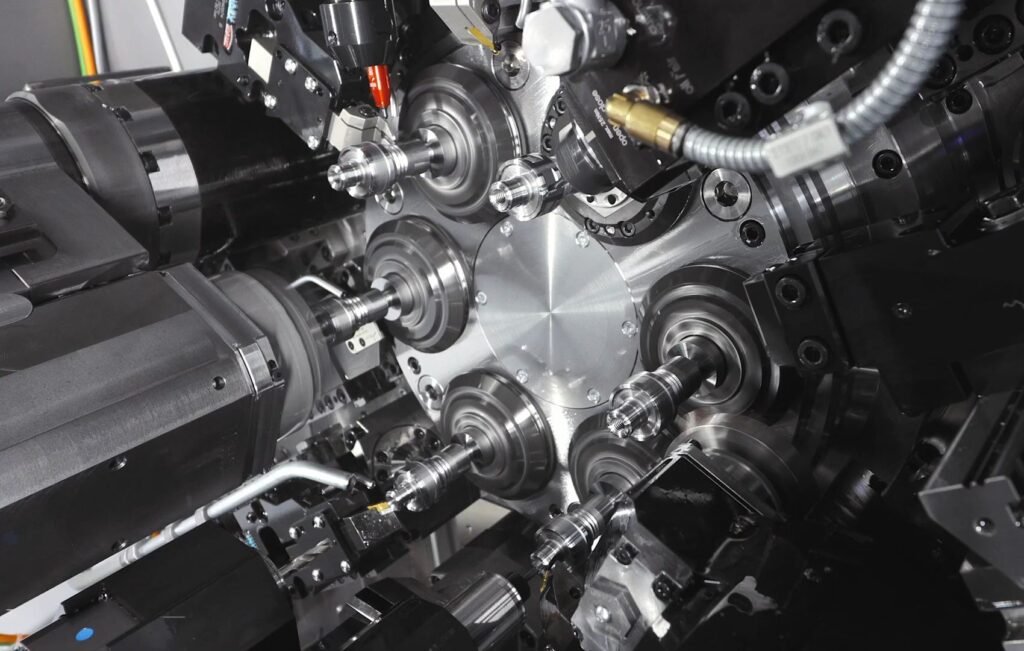

Multi-axis Machining

Our multi-axis machining services enable the processing of complex geometries by simultaneously machining multiple faces of a part. This reduces setup time, minimizes errors and improves accuracy. We use advanced multi-axis CNC machines to produce high-precision components for demanding industries such as medical devices and high-precision electronics. Our technology integrates CAD/CAM systems to ensure precise control and high-quality results, whether for small batches, prototypes or large-scale production.

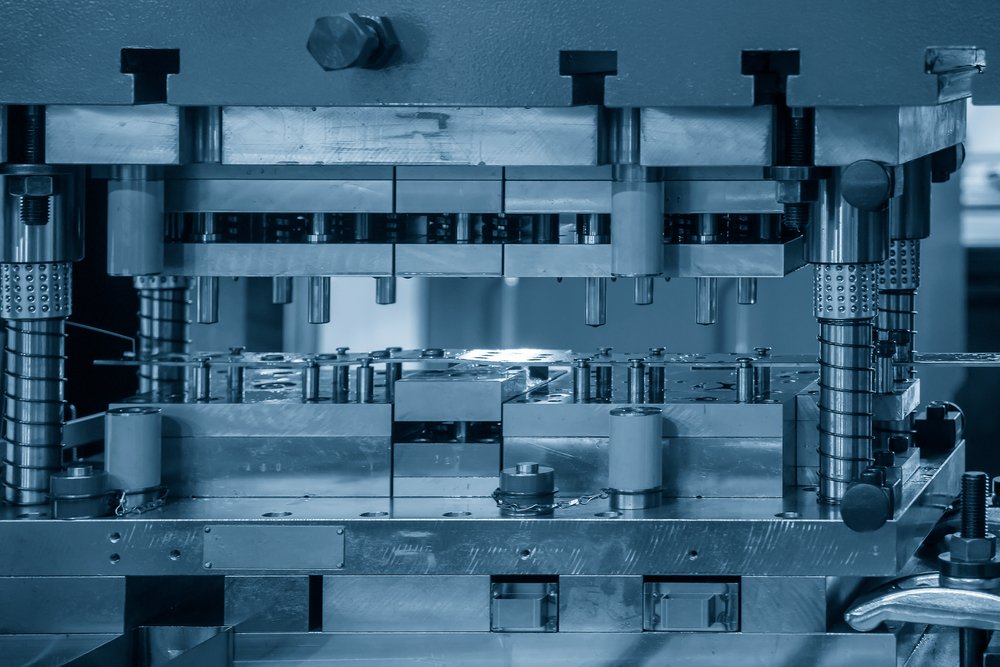

Micro-stamping Process

Our micro-stamping services cater to the production of small-sized metal parts with micron-level precision. Using high-precision molds and stamping equipment, we produce components with complex shapes and fine details for industries like electronics, medical devices and telecommunications. This process improves efficiency and reduces costs while maintaining high quality and precision. Whether producing sensors, micro connectors or other miniaturized components, we ensure each part meets stringent quality standards.

In all our services, we integrate advanced materials science, equipment and rigorous quality management to provide customers with customized and high-performance solutions that meet their exact needs. Whether for prototyping, small-batch production or large-scale manufacturing, we help clients reduce costs, shorten development cycles and enhance product performance.

.png)