At ZW Precision Hardware, we recognize surface treatment and heat treatment as essential processes in metal component manufacturing, enhancing both material performance and longevity while ensuring superior aesthetics. These treatments play critical roles in improving durability, functionality and overall product quality.

Surface Treatment: Protection and Aesthetic Enhancement

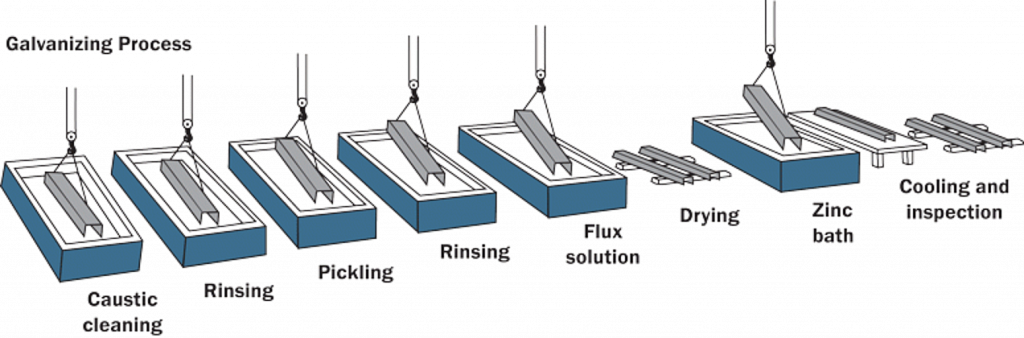

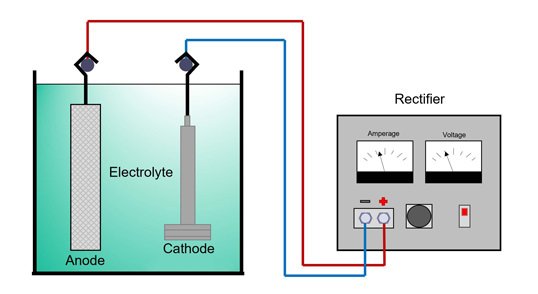

Surface treatment enhances corrosion resistance, wear resistance and visual appeal by applying a protective layer to metal components. Our advanced surface treatment techniques include galvanizing, nickel plating, oxidation, coating, polishing and electroplating. These processes not only increase durability in harsh environments but also meet stringent functional and aesthetic requirements. Surface treatment is widely utilized for spring assemblies, stampings, pressings and wire forms, particularly in industries where high precision and durability are paramount for both industrial and consumer applications.

Heat Treatment: Strengthening Mechanical Properties

Heat treatment is a crucial process that alters the internal microstructure of metal components to optimize key mechanical properties such as hardness, toughness and fatigue resistance. Our heat treatment capabilities include quenching, tempering, annealing and surface hardening, ensuring enhanced performance and structural integrity. For springs and complex mechanical parts, heat treatment is vital to achieving high strength, elasticity and long-term reliability. These processes enable components to maintain stability under high stress and extreme temperature conditions, extending their operational lifespan.

Integrating advanced surface and heat treatment techniques, we ensure our metal components meet the highest industry standards. By leveraging these processes, we enhance product performance, extend durability and provide tailored solutions that cater to the diverse needs of industries requiring precision-engineered components.

.png)