We offer a range of advanced manufacturing services using cutting-edge technologies like CNC machining, multi-axis machining and micro-stamping process to produce high-precision components for various industries.

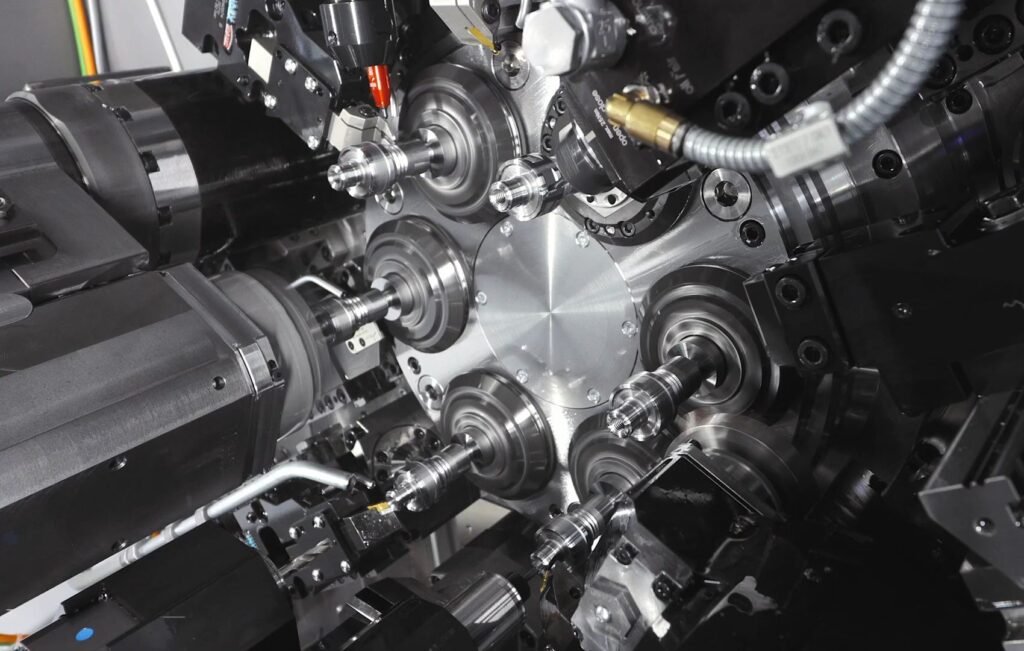

CNC MACHINING

We provide high-precision CNC machining solutions that include milling, turning, drilling and grinding. With advanced CNC technology and a variety of machines, including five-axis and CNC lathes, we can handle complex parts for industries like aerospace, automotive and medical devices. Our efficient processes, precise CAD/CAM programming and strict quality control ensure that we deliver high-quality, reliable components for both small and large production runs. In addition, we offer value-added services like material selection and post-processing to meet our customers’ specific needs.

MULTI-AXIS MACHINING

Our multi-axis machining services enable the processing of complex geometries by simultaneously machining multiple faces of a part. This reduces setup time, minimizes errors and improves accuracy. We use advanced multi-axis CNC machines to produce high-precision components for demanding industries such as aerospace, medical devices, and high-precision electronics. Our technology integrates CAD/CAM systems to ensure precise control and high-quality results, whether for small batches, prototypes, or large-scale production.

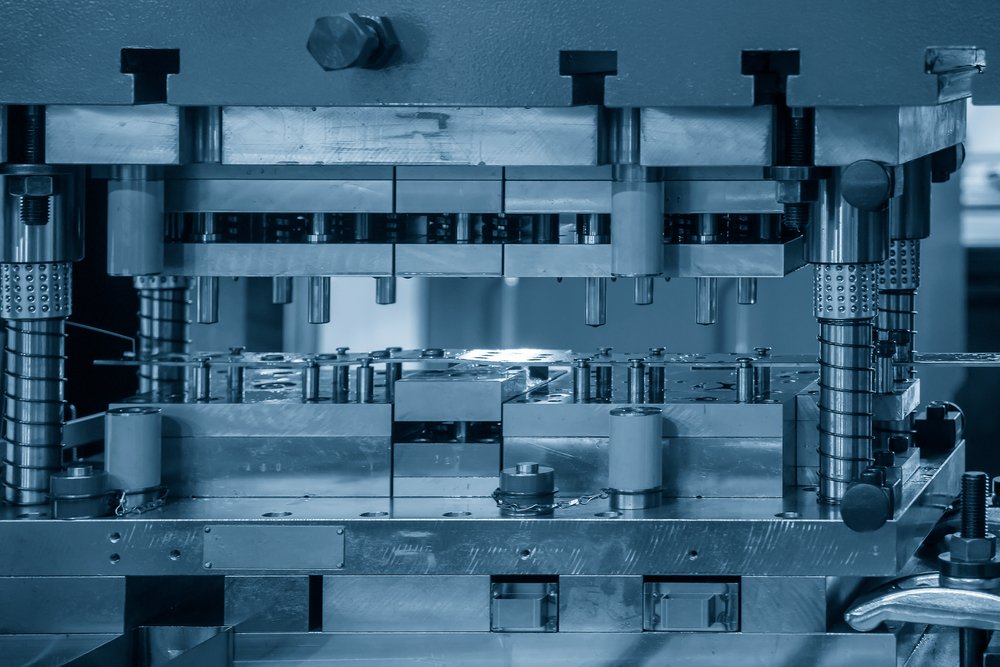

MICRO-STAMPING PROCESS

Our micro-stamping services cater to the production of small-sized metal parts with micron-level precision. Using high-precision molds and stamping equipment, we produce components with complex shapes and fine details for industries like electronics, medical devices and telecommunications. This process improves efficiency and reduces costs while maintaining high quality and precision. Whether producing sensors, micro connectors or other miniaturized components, we ensure each part meets stringent quality standards.

HOW WE DO BY MULTI-PROCESS MACHINING

We own different series of multi-function forming machines to support our manufacturing processes. Forming machine series are combined with many advantages, cooperating with precision manufacturing to full play its production capacity, which with high precision and strong productivity, using multi position design to finish wire feeding, stamping, and bending forming in one time continuously. They can produce the product with well surface, steady angle, high accuracy, Fast and Less waste after forming, which is a powerful tool in the forming machinery industry area.

The following is a showcase of some of the equipments:

| MODEL | CMM-12-236R Transfer Machine | ||

| Wire Diameter | 0.4-2.3mm | ||

| Max.Wire Feed | 10000.00mm | ||

| Min.Wire Feed | 0.01mm | ||

| Max.Wire Feed Length | Infinite length | ||

| Number Of Axes | 12 axes (including servo angle bender/Spinner) | ||

| Power | 14.75KW | ||

| Voltage | 380V | ||

| Software | Pentium Industrial Computer/Intel | ||

| Program Storage | Over 2000 | ||

| Voltage Regulator Power | 15000W | ||

| Air Compressor System | Air pressure | 5-6KG/cm | |

| Air cylinder | 3 pieces | ||

| Dimensions | Depth | 2020mm | |

| Width | 1440mm | ||

| Height | 1800mm | ||

| Machine Weight | 1700KG | ||

| MODEL | CMM-12-430R | ||

| Wire Diameter | 1.5-4.3mm | ||

| Max.Wire Feed | 10000.00mm | ||

| Min.Wire Feed | 0.01mm | ||

| Max.Wire Feed Length | Infinite length | ||

| Number Of Axes | 12 axes | ||

| Power | 26KW | ||

| Voltage | 380V | ||

| Software | Pentium Industrial Computer/Intel | ||

| Program Storage | Over 2000 | ||

| Voltage Regulator Power | 30KAV | ||

| Air Compressor System | Air pressure | 5-6KG/cm | |

| Air cylinder | 3 pieces | ||

| Dimensions | Depth | 3540mm | |

| Width | 2240mm | ||

| Height | 2200mm | ||

| Machine Weight | 4845KG | ||

| MODEL | CMM-12-610R | ||

| Wire Diameter | 2.8-6.0mm | ||

| Max.Wire Feed | 10000.00mm | ||

| Min.Wire Feed | 0.01mm | ||

| Max.Wire Feed Length | Infinite length | ||

| Number Of Axes | 12 axis (including servo angle bender/Spinner) depending on configuration | ||

| Power | 60.4KW | ||

| Voltage | 380V | ||

| Total Output Torque | 4036N | ||

| Software | Pentium Industrial Computer/Intel | ||

| Program Storage | Over 2000 | ||

| Voltage Regulator Power | 30kW | ||

| Air Compressor System | Air pressure | 5-6KG/cm | |

| Air cylinder | 5 pieces | ||

| Dimensions | Depth | 3470mm | |

| Width | 2200mm | ||

| Height | 2320mm | ||

| Machine Weight | 9000KG | ||

| Force (kN) | 350 | |

| Max. bending Length (mm) | 1250 | |

| Distance between uprights (mm) | 900 | |

| Opening height (mm) | 385 | |

| Throat depth (mm) | 200 | |

| Cylinder stroke (mm) | 120 | |

| Main power (kw) | 3.7 | |

| Oil(L) | 70 | |

| Upper beam Speed (mm/s) | Approaching speed | 150 |

| Working speed | 0-15 | |

| Returning speed | 160 | |

| Back gauge speed X axis | Stroke (mm) | 450 |

| Max. speed (mm/s) | 450 | |

| Back gauge speed R axis | Stroke (mm) | 100 |

| Max. speed (mm/s) | 75 | |

| Machine Dimensions (mm) | Length | 1500 |

| Width | 1200 | |

| Height | 2285 | |

| Weight (kg) | 2500 | |

In all our services, we integrate advanced materials science, equipment and rigorous quality management to provide customers with customized and high-performance solutions that meet their exact needs. Whether for prototyping, small-batch production or large-scale manufacturing, we help clients reduce costs, shorten development cycles and enhance product performance.

| Model NO. | HS-926 | Process Usage | Metal-Cutting CNC Machine Tools, Multi -Axis CNC Lathe |

| Movement Method | THK,PMI | Control Method | Metal |

| Numerical Control | Multi -Axis CNC Lathe | Processing Precision | 0.05~0.06(mm) |

| Performance Classification | CNC Lathe | Certification | CE |

| Specification | 1550*1060*1650mm | Production Capacity | 60sets/Month |

| Processing references | Maximum machining diameter | Φ26mm | |

| Maximum machining length | 190mm | ||

| Maximum axial bore diameter | Φ10mm | ||

| Maximum axial work wore size | M8 | ||

| Maximum spindle speed | 10000rpm | ||

| Radial max bore diameter | Φ7mm | ||

| Radial max bore tapping size | M6 | ||

| Radial power head max rotation speed | ER11:10000/ER16:8000 | ||

| Rated speed of radial power head | ER11:8000/ER16:6000 | ||

| Max workpice removal length | 100mm | ||

| Tool dimension | Number of knives installed | 6 | |

| Turning tool | 12X12 | ||

| Sleeve | Φ25.0 X 4 | ||

| Clip head guide sleeve | Spindle spring collet | TSUGAMI B0265CCR | |

| Power head collet | ER11,ER16 | ||

| Guide bushing | TSUGAMI BS-20#-B | ||

| Feeding speed | Z1/Z2/X2/Y | 30m/min | |

| Z1/Z2/X2/Y-asis feed velocity | |||

| X1 | 20m/min | ||

| Electric motor | Spindle drive power | 2.5/3.7KW | |

| Power head drive power | 1KW | ||

| For cutting fluid | 0.4KW | ||

| For cooling of spindle | 0.075KW | ||

| For lubricating oil | 0.01KW | ||

| Others | Spindle center height | 1060mm | |

| Barometric flow | 0.7mpa 0.5m³/min | ||

| Main circuit breaker capacity | 40A | ||

| Input power | 9.3KW | ||

| Weight | 2.6 | ||

| Overall size | 2250X1200X2000mm | ||

.png)